Veepee, iTek Packz collaborate to produce stunning DuPont desk calendars by flexo process - The Noel D'Cunha Sunday Column

Printing calendars have always been in the realm of sheetfed offset process. Here the two companies with their combined know-how have displayed why flexo as a print process is a technology to reckon with.

This Sunday Column finds out how the calendar production was well put together

24 Jan 2021 | By Noel D'Cunha

Flexo, a process long considered second to offset and gravure has made strident progress. DuPont, a formidable force in the flexo plate and platemaking technologies, has upped the ante. It has a long history of continuous innovation for flexo plates and platemaking systems to deliver high quality and high precision.

DuPont’s drive to push the flexo print process further made the company to explore printing its annual calendar using the technology it was far too familiar with. Two years, ago it collaborated with two of its long-term partners, Bengaluru-based companies – iTek Packz and Veepee Graphic Solutions, to produce calendars using flexography.

The collaborators

When ITW Signode decided to sell the folding carton business, about 20% of the Wintek business, along with 60 employees engaged in the business, the second generation of the Wintek owners, who were also employees of ITW Signode after the acquisition, decided to buy it. In 2013, a partial team exited ITW and formed iTek Packz.

iTek started with a six-colour sheetfed press doing folding cartons. Gopi Ballarwad, who looks after the commercial part of the folding carton business says, Gassali, one of the partners who was sound with the flexo technology, wondered why iTek could not produce folding cartons on flexo. “In 2016, we visited a folding carton specialist in Manchester, United Kingdom. The company printed short-run job orders of 500 and 1,000 cartons on its Edale flexo press. We were impressed with the business model and decided to invest in the press.”

iTek’s flexo journey began with the installation of Edale FL5 flexo press in February 2017. It was a 10-colour flexo press with inline cold foiling, lamination and die-cutting units capable of running at a maximum speed of 200 m/min and print on substrates as thin as a 12-micron shrink sleeve film to 650-micron paperboard. “While doing the trials, we found we could produce quality cartons, quickly, and we could do the embellishments, all in one go.” In September 2019, the company installed a second Edale FL3 flexo press, a nine-colour configuration to boost its label printing capability.

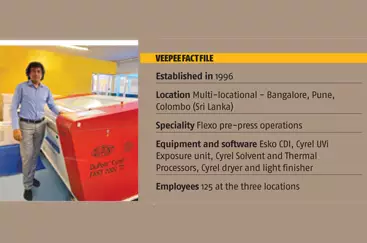

Veepee Graphic Solutions, the other DuPont collaborator in the calendar project, is among the top three flexo platemaking trade shops in India. Veepee is a process-oriented pre-press house. Everything has a standard operating procedure (SOP), which you usually don’t find in trade shops – be it flexo, offset or gravure.

The flexo pre-press specialist has been a DuPont customer since 1998. “We have been DuPont loyalists for over two decades,” says P Jaichandra, managing director at Veepee, which recently installed DuPont’s Cyrel Fast 2000TD solvent-less processor, the only trade shop using the device, and also rolled out DuPont’s new Cyrel Easy EFXR plates.

Going a level higher

The first two editions of the DuPont calendar were well received by the industry.

This time the theme was “Dances of the world”. Dance being an expression of the soul, has multiple emotions, it is a combination of art, culture and joy. Images were chosen based on printability and global appeal.

This was not like a regular job for us, says Jaichandra. The design planned had quite a few embellishments. “With a normal four-colour print anyone can make the calendar look different or, I’d even say outstanding. But here we focused on complementing the images through embellishments.”

The design and prepress took a good one month from the day Veepee received the images from DuPont till the first final print. Each and every single image was individually worked upon. Jaichandra says, “We were given an open hand to decide what exactly we wanted for the images.”

Jaichandra adds, “We began with profiling the press for this particular substrate [ITC’s virgin board]. We had done the profiling of the press and the substrate for the past two calendars, but then DuPont wanted to print 2021 calendars with the soon to be launched Cyrel Easy EFXR plates. Hence we created a new profile.”

From the design files to working on Adobe Photoshop the separations were accurately generated, including a complex white colour. “We produced the plate with a screening of 150 lpi to create the finest image reproduction. We have played around with varnishes, overcoating and also with foil,” explains Jaichandra.

The EFXR plates were processed on the Fast 2000TD solvent-less processor. “When we did the fingerprint using the substrate we found the ink lay with the EFXR plate was better than the solvent processed DuPont plates which we usually consume. This was a pleasant surprise because, with the solvent plates, we have to get into the nitty-gritty of improving the ink lay. This was the first time we didn’t have to do it,” remarks Jaichandra.

Cut to printing

iTek Packz printed calendars on the Edale FL5, which Ballarwad says, has enabled his company to win numerous international awards owing to its print quality, notably among them is the Flexographic Technical Association (FTA), New York, USA.

The 16-page calendar was printed on ITC’s virgin board. Barring the two-colour month and date, which was sheetfed printed, seven-colour flexo printing – CMYK plus orange, green, violet (OGV) and white. Each of the calendar pages were decorated with different embellishments like cast and cure, texture, gloss and matte varnish, foil and drip off.

Ballarwad says, “Every other page is treated with a different set of embellishments depending on how the design has to be accentuated. For example, the first month, January 2021 has Bharatanatyam as the theme. It has a silver foil, CMYK, OGV plus white, drip-off and gloss varnish. The white here is used uniquely. It is printed such that it gives the image additional opacity where required in the design.”

iTek used CMYK UV, OGV UV and varnish inks from various ink manufacturers. For iTek it was also the first time it was printing a job using the new EFXR plates.“Printing halftones with the new plates was a new experience. We could produce high-density print with very fine dots,” says Ballarwad, giving the DuPont EFXR plates his stamp of approval.

iTek has been constantly pushing the boundaries of flexo print process. Ballarwad explains, “While the cartons we have sent for awards did have embellishments, it’s our ability to produce halftone and dot quality that has earned us the recognition at FTA Awards for three consecutive years.”

Both Veepee and iTek have a common strategy – invest in the right equipment and technology, harness it and get the best out of it.

The two Bengaluru companies and their supplier, DuPont, have been working together to take flexo print process a notch higher each time. The flexo printed DuPont calendars are a result of such efforts, showcasing flexo technology to be capable of competing in mono carton or board printing which can open new avenues for the industry.

DuPont’s Take

A good validation of the trio’s success is that for the third year running, the DuPont Calendar is produced in collaboration with iTek and Veepee. Both iTek and Veepee have been customers for a long time and are masters of their respective fields. They always strive to do something unique. The two companies understanding of the flexo process is immense.

See All

See All