How QFP is producing 4,00,000 books per day

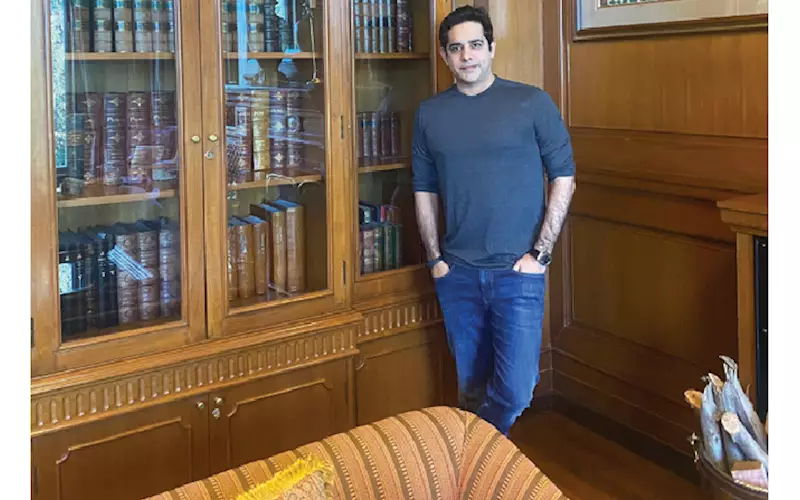

Within a span of eight years, Quarterfold is now one of the youngest and most enterprising book presses in India. “With continuous investments in production sources, our main focus has always been in the education sector, both in Africa and India,” founder and CEO Nilesh Dhankani. Words: Ramu Ramanathan

17 Feb 2022 | By PrintWeek Team

Quarterfold has installed the complete binding line of a Signa 16-station gatherer with WB@4000 inline and offline trimmers, standalone WB@3600 12-clamp binder, four stand-alone WB@2500 six-clamp binders. When PrintWeek asked Nilesh Dhankani, founder and CEO of Quarterfold Printabilities (QFP) about the rationale behind this investment, he replied, “Preparation is key. Even with the pandemic, we had to react quickly to the changing circumstances. With customer requirements increasing by the day, publishers have to keep up with the rising trends and demands of this ever-emerging market. This is what makes it inevitable for us to expand in line with their vision.”

Dhankani feels QFP has managed to adapt and pivot its set-up to help maintain steadiness in its operations. The company has expanded exponentially by adding a second factory and a fleet of double tower web machines; all in a matter of five months.

The fundamental attitude of QFP is to never say no to its publisher partners. For instance, during the peak of the pandemic, Quarterfold had to deliver two simultaneous projects with over eight million books in a time frame of 30 days. The task was completed in 26 days. “No matter how challenging the job, we never shy away from supporting our publisher friends. I guess that’s what makes us the pioneers in the educational printing domain,” says Dhankani.

QFP has not been resting on its laurels...

Dhankani says, “We have executed large projects and shipped close to 150 containers from both our factories within 45 to 50 days. Our benchmark is to ship out 60-plus (40ft containers) each month for the next financial year.”

Techno-commercial strategy

Both the QFP factories are in Taloja MIDC in Mumbai. The collective size of the factories is over 1.2 lakh sqft (with additional 15,000 sqft for packing and dispatch). And so, what started as a dream metamorphosed into QFP in 2014. A year ago, the company expanded to a second factory in the areas of print management, content development and publication support for its clients in the continent of Africa.

Dhankani explains the business logic behind this investment, “Our business is driven by consumption, which makes it all the more essential for us to meet the increased and varied demand of the print segment, head-on.”

The recent post-press investment will help Quarterfold in the production of books for the education sector. Dhankani says, “Our focus has always been the education sector.” QFP has been pivotal in executing major runs for its publisher partners (both in India and abroad). It’s forte: paperback hotmelt and section-sewing perfect bound books. With this new post-press installation, QFP has managed to enhance its capacity, reduce throughput time, and focus on automation and lean manufacturing.

At the moment, the factory boasts of serious press arsenal: a battery of 6x16-page four-colour web presses, 2 x 32 page Hi Tower four-colour web presses, four-colour sheetfed presses, 3 x 12-clamp binders + 2 x 16 station feeders withinlinetrimmers, 4 x 6-clamp binders, 12-station offline gatherer Muller saddle-stitcher, cold lamination, offline UV, foiling, punching, shrink wrap, and digital press.

When we enquired about how the installation process was, Dhankani says, “There are always going to be things to watch out for with web press installations. However, we are very well aware of our optimal needs because of our thorough understanding of our customers and the market trends in general.” He prides himself on having a dynamic team, which is backed by solid technical background. “The installations were a breeze”, he says.

QFP believes in the Willy Rogers quote: Even if you’re on the right track, you’ll get run over if you just sit there

Systems in place

How were the past 12 months for QFP in both the domestic and exports market? Dhankani says, “We have done well in 2021 and our revenues are back to pre-pandemic levels.”

One reason is the type of best practice being adhered to in the factory. The team has strived to achieve organic growth and trust from its customers. With innovation, new and continued developments in technology and in-house manufacturing, QFP has seen growth across all verticals.

Dhankani shares, “The best of the technology from industry is installed on our shopfloor that has always been handled by some of our best skilled operators and technicians. Our partners in growth - Impel-Welbound Group / Impel Services - conducts and provides the best in-house training to our operational staff on a regular basis.” And so, QFP has successfully done some of the most challenging turnarounds for its clients. The quality system and robust MIS ensures that the right product gets manufactured at the right time and in the right manner.

Dhankani says, “The team has matured to handle tasks effectively that include, but are not limited to: thoroughly studying the jobs, detailed project reviews (both pre- and post), daily analysis on performance and deliverables, online QC, control measures, waste monitoring, up to date MIS reporting and so on.”

He adds, The best of the technology is installed on our shopfloor that has always been handled by some of our best skilled operators and technicians. Our partners in growth - the Impel-Welbound Group- conducts and provides the best inhouse training to our operational staff on a regular basis.” And so QFP has successfully done some of the most challenging turnarounds for its clients. The quality system and robust MIS ensures that the right product gets manufactured at the right time and in the right manner.

From printing to box packing of the books, everything is done in both the facilities. QFP follows a lean manufacturing process that maximises productivity, reduces wastage and helps the group offer premium quality to its customers.

He adds, best practice is an ongoing process. I have always believed in empowering people, as that freedom helps in getting the best out of them. And yes, we are learning constantly, we are getting better, daily.”

Building on their strengths

Despite the pandemic, the company decided to take a risk and set up a new factory. The rationale behind it is Dhankani’s aim “to provide educational publishers with outstanding print services, delivery in short lead times and no compromise on quality.” These are calculative risks as QFP has a thorough market understanding and healthy projections. It took the company years of experience and market research to derive these risks.

The pandemic era has been tough. Dhankani says, “Over time and with continued investments in innovations and manufacturing developments (mainly to address the needs of our customers) I take utmost pride in saying that all of our customers are happy. They appreciate the risk we take and the efforts we put to fulfil our delivery commitments. We are truly honoured to gain their trust and respect.”

Looking ahead, Dhankani says, “Like I mentioned earlier, our line of business is consumption-driven and it is very essential to cater to both export and domestic markets. However, the good thing is that varied markets have varied timelines for delivery and this is what helps us effectively roll out projects throughout the year. I would not deny that there are times when we have had tremendous pressure when we receive unseasonal jobs (mainly from the export market).”

But then, that is the challenge the team at Quarterfold has perfected. It is a young team of dynamic and thorough professionals. And they seem to be book-ready.

Impel-Welbound Group / Impel Services installation at QFP

Description of the kit

Bindline @4500 with Signa Gathering, a perfect binder, conveyor and Trimit 30C

Speed of production

3500-4000 CPH on pallet

Key features

Online, state of the art, quick changeovers

One feature that impressed you

Automation; and its interface for operational controls

Tech support

On time, reliable and proven

Pallippuram Sajith, managing director, Impel Services (A Welbound group company) says, the general trend for book printing companies in the early days of exports to Africa was to invest in brand-new European binding machines. Then this changed with Indian printers opting for used equipment so as to keep the costs under check. This backfired badly due to “cost” of operating used equipment - be its inefficiency or huge costs of maintenance. Plus the quality issues that prevented them access to good publisher accounts. QFP has done the smart thing by investing in brand new Indian bookbinding line that is efficient and cost-effective.

“The Bindline 4000 series inline binders require 40% investment and 25% of the maintenance costs as compared to a brand new European machine. And these new machines deliver at least 30% more throughput consuming 50% energy and space compared to used equipment,” says Sajith.

See All

See All