Bobst Ambition installation props up Neo Print N Pack packaging operation

The new Ambition 106 A2 has given the Bilimora-based packaging specialist in Gujarat a productivity boost.

06 Mar 2023 | By Noel D'Cunha

Neo Print N Pack in Bilimora has invested in a brand new Bobst Ambition 106 A2 folder-gluer that includes a four- and six-corner attachment; and a corrugation kit that will allow the packager to fold and glue corrugated boxes.

The new machine will complement its existing 1964-made Bobst folder-gluer and an India-made Al Fareed folder-gluer.

Nilam Naik, the CEO of Neo Print N Pack, said that the India-made folder-gluer was an emergency buy that he had to make to meet the demands during the initial period of the Covid-19 pandemic. "It's the Bobst Ambition 106 A2 that has played a key role in the success of our packaging business."

Speed and cost benefits

Before the new kit's installation, Neo produced four-corner pasting manually and required seven to eight people to do around 1.50-lakh mono carton boxes per day in an 8-hour shift. The operation would cost around 50 paise (Rs 0.50) per box, which includes the wastage of expensive adhesives and paper. Naik said, "Today, we produce the same number of cartons in two hours at the cost of 15paise, saving on wastages of adhesive because we use as much is required for the operation."

Naik entered into the packaging business in 1997, establishing a corrugation packaging plant. The corrugation business, Nipon Paper Product operated in a 32,000 sqft site in Bilimora, with three corrugation lines to produce c-, e- and broad-flute boxes.

In 2007, Naik moved into printing as Noble Offset, a small operation with a two-colour Heidelberg press and manual finishing machines to produce mono cartons. "It also supported the corrugation business because we used to outsource our printing job before we started Noble," said Naik. "After getting the experience of printing, in 2012 we established Neo Print N Pack at a new two-floor building on a 25,000 sqft plot, catering to both mono carton and corrugation."

Challenges along the way

While the corrugation business was in operation along with Neo, tragedy struck. Naik's brother Narendra, who was part of the business and management, could not pay attention to the company as his wife was diagnosed with cancer. She passed away a couple of years later, after which his brother withdrew from the business.

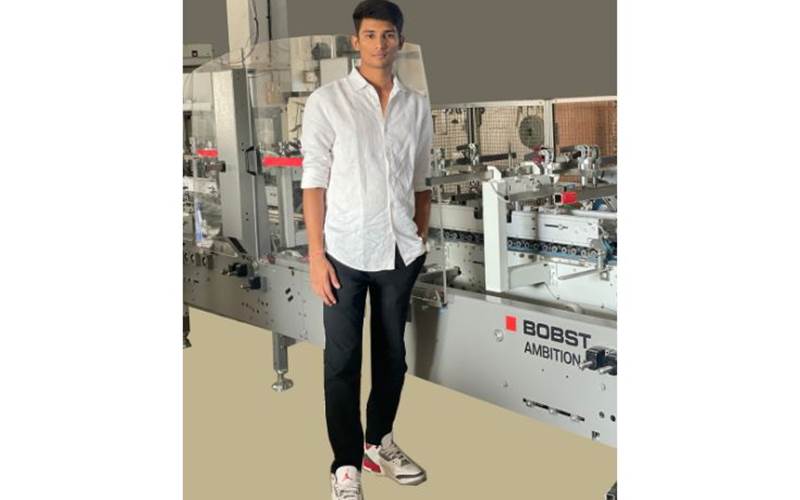

Nevil Naik with Neo Print N Pack products

Unable to cope with the pressures of the two businesses, Naik stopped the corrugation operation and concentrated on the mono-carton business. In 2017, he restarted the corrugation business shifting the operation to the Neo site, and continued to manage the companies.

Three years ago, Naik's son, Nevil, a civil engineer, joined the business and has been assisting Naik in running the packaging business.

Naik explained, "We restarted the corrugation business, but printing related. That business continues – producing micro-, e- and c-flute packaging boxes, supplying to clients in different industries including pharma."

The business curve

Neo converts around 220 tonnes of paper and paperboard monthly, close to 150 tonnes for mono cartons. Around 60% of the company business comes from mono-carton packaging, and 40% is corrugation, with a business turnover of nearly Rs 20-crore.

The company is equipped with a raft of single and multi-colour presses from Komori, Heidelberg and Oliver; punching and window lamination machines; offline coaters; and a UV conveyor for metalised and UV coating among others, for producing mono carton boxes. The corrugation has a 42-inch Comby corrugation machine; a pasting machine; two punching machines; and two stitching machines.

Naik added, "There's a strong demand for innovative corrugated packaging solutions, and the Bobst Ambition has been helpful."

Some processing plants need packaging to preserve and hold their products in freezing temperatures. While substrate, ink and adhesive are as important, delivering the finished products is also essential. Besides the demand from other industries, Bilimora, a coastal area, is also home to the fishing sector.

"Folding-gluing is the final stage of packaging that fuses the printed carton and adhesive to produce folded cartons ready for packaging. The lock-bottom feature and its precision become critical," said Naik, adding, "With the Bobst Ambition 106 A2, we are now able to handle an entire range of jobs rather easily."

In 2020, Neo found an equity partner which has infused funds into the business, and is a 50% partner. "It was a push we needed for our business and operations," said Naik, without disclosing further details. "We have decided to expand our packaging business and acquired a one-lakh sqft plot in Bilimora. We will move our operations to this bigger site with more machinery."

Neo, which employs 80 people, hopes to move to the new site by 2024 with a new name, and hopes to grow three times its size. "With the help of some exciting investment plans, we hope to grow into new markets and challenger brands that have sprung from the Covid-19 pandemic," Naik concluded.

See All

See All