Women in print, and the value they bring to their print businesses - The Noel DCunha Sunday Column

In today’s Sunday Column, Part III in the series of Women to Watch, are seven women across an array of print departments, from pre-press to press, handling design, plate production or development of new products. These seven women share their experiences, their challenges and how they excel. Read on...

24 Feb 2024 | By Noel D'Cunha

Ayushi Keshri, packaging development manager, Cargill India

As a packaging development manager, Ayushi Keshri is responsible for designing and developing innovative packaging solutions that meet the needs of clients or customers. It involves creating prototypes, running tests, and assessing the performance of the packaging.

Keshri explains, "My responsibility is to ensure that the packaging material is both stable and cost-effective while also meeting regulatory requirements." For this, Keshri collaborates with different departments to coordinate processes and procedures, develop specifications, and implement SOPs and work instructions that will enable the organisation to achieve its objectives. "I also work to identify and resolve any operational issues in a timely manner."

Recently, Keshri worked on developing a solution for the long‐standing market complaints regarding neck buckling and body damage to the Rath 15-litre bucket SKU. “After multiple trials and valuable feedback, we designed a special die-cut carton that can increase the vehicle load ability and keep the buckets safe during transportation and storage.”

The result: a two-fold increase in productivity that exceeded the company’s initial expectations. “Not only has our new packaging solution delivered exceptional results in terms of productivity, but it has also received overwhelming positive feedback from our customers. Consumers have reported that the packaging is both functionally and aesthetically pleasing, demonstrating our commitment to providing consumer-centric solutions that meet their needs and exceed their expectations,” says Keshri.

Ekta Chandan, founder, Aum Paper Products

.jpg)

Aum Paper Products is a Bangalore based ISO 9001:2015 and FSC-certified company specialised in the manufacture of paper packaging.

After 16 years of management and packaging development experience, Ekta Chandan founded Aum Paper Products in 2020. “I wanted to develop packaging solutions with a vision of Aaum, the spiritual chant that resonates with human conscience,” says Chandan. She also believes in sustainable business, whether it is about sustainable economic growth or environmental sustainability.

Chandan has done her MBA from a university in USA, and is also a board member and serving director in the parent company, Trimurti Group of Companies.

Aum offers solutions for eCommerce, FMCG, and retail. The company serves large- and medium-sized businesses, including eCommerce giants. Chandan aims to make the company the largest sustainable packaging company. "We purchased four acres of real estate for immediate expansion needs and plan to generate 50% of their energy from renewable resources," says Chandan. The company aims to be carbon neutral by 2030 to align with its core mission of creating sustainable packaging solutions.

Chandan's drive for innovation stems from her frequent visits to customers' warehouses, where she gains a better understanding of changing requirements. During one visit, she noticed the need for more efficient packaging. This led to the development of a two-ply expandable corrugated mailer envelope as a sustainable alternative.

This envelope is designed for packaging and transportation needs. It has crease lines to allow expandability and comes with single or double glue strips. The dual glue strip is primarily used for reverse logistics. “It is also tamper-proof. It can be numbered all around, and a tear tape is provided for easy opening. A special ink across the flap turns pink when it comes in contact with heat, indicating any tampering,” explains Chandan.

The two-ply expandable corrugated mailer envelopes challenge conventional packaging and are not only cost-efficient but environmentally friendly.

Aum Paper Products has become one of the fastest-growing companies in India. Recently, the company won the Quality Excellence Award at the India 5000 Best MSME Awards 2022.

Right from procurement of raw materials to delivery of finished goods, Chandan continuously ensures the vision is always kept aligned in everything that the company, Aum, does.

K Indhumathi, owner, Mandagini Agencies

Born in a family in businessmen and married into a family in the packaging domain, K Indumathi has been there and done that.

Managing a women's empowerment organisation that focuses on delivering high-quality, high-quantity, recyclable, biodegradable, sustainable, and user-friendly products, Indumathi's main task is to oversee and control operations, leading a team of well-qualified women technocrats.

According to Indumathi, changes in the packaging sector are constant and unavoidable. “Our main objective is to provide innovative and valuable products that meet the needs of manufacturers and ultimately satisfy consumers. We aim to help our packaging customers achieve a zero environmental footprint by 2025.”

While sharing glimpses of her achievements, Indumathi says the optimised packaging design process adopted by Mandagini has resulted in a 20% faster turnaround time without compromising quality, streamlined production workflows, reducing production time by 15%, resulting in significant cost savings. “We have developed and designed packaging for 50+ products, which has resulted in increased brand awareness and sales,” says Indumathi.

The see-through specialty sealing wads Mandagini produces blend elegance with quality. “The increasing importance of product presentation has led to higher expectations from consumers in the era of artificial intelligence. With a scientific background, we prioritise both inner and outward presentation to meet customer needs and expectations,” says Indumathi.

The result: An enhanced wad outlook that is transparently elegant revealing inner content. It consumes less board, sealant and temperature threshold, making it a cost-effective product. “One can pull it open, peel the seal or feel the seal,” says Indumathi about the ease and convenience of handling the product. The wads are inert, non-reactive and have an oxygen barrier, which protects and preserves the packed product’s nature.

The company also produces eco-barrierr bio-board, which Indumathi claims has properties such as oil, water, and aroma retention, is 100% seepage proof and is eco-friendly.

Kaveri Satija, Janvi Arts

The 21-year-old Kaveri Satija is a business manager with a diverse skill set, including designing, machine operations, accountancy, and overall management. Satija has undergone specialised training in flexopolymer platemaking through the Flexography Technical Association.

“My passion for design started at a young age, and I have spent countless hours perfecting my skills using various software tools like CorelDraw, Adobe Photoshop, and Adobe Illustrator,” says Satija. Her design and machine operations expertise enables her to multitask efficiently, ensuring that projects are completed on time and to the highest quality.

Satija started working with the graphic design team at her family-run business, Devi Graphics, over four years ago. She quickly progressed to head the team while also managing client relationships. By early 2022, Satija considered diversifying its offset pre-press business to the flexo industry. "After evaluating technology options, we decided to invest in a flexo pre-press set-up. I also gained formal education through online courses from the US Flexographic Technical Association (FTA). That's how Janvi Arts was established."

With this newly diversified flexo pre-press house in 2022, Satija took on new responsibilities as a full-time business manager, leading client relationships, operations, and accounts. This involved putting her academic understanding into practice while learning with the help of experienced professionals how each variable in flexo pre-press needs to be closely controlled in order to get an optimum digital flexo plate that performs well on press. “At 21, setting up and running a flexo pre-press business has been one of my biggest achievements,” says Satija.

And then came bigger success. In an industry where years of experience is a standard ask, using her skillset and tenacity to win the trust of customers has been Satija’s most valuable success. “Every interaction with my clients and even within my team reaffirms my commitment to continue persevering to deliver more and better than the day before,” explains Satija.

The efforts paid off when Satija won three big label converter accounts - Leo Packaging, Arihant Labels, and Grand Tech, all three on the same day. Of course, many more followed.

Preeti Jaiswal, AGM NPD and MR, Jupitar Laminators

A mechanical engineer with 15 years of experience in flexible packaging, Preeti Jaiswal says her objective is to provide sustainable packaging solutions to her company’s customers.

Jaiswal’s journey in Jupiter has allowed her to work on different fronts, such as new product development, quality assurance and several certification compliances. “My learning curve has been very high, and this has encouraged me to do little more than what is expected,” says Jaiswal.

Under Jaiswal’s leadership, Jupiter developed a new product for a customer, which was a success. “We are supplying approximately 20 MT of the said product per month.”

On the other hand, Jupiter has developed paper and foil base lamination, which supports wrapping sandwiches/burgers. “The paper side keeps the packaged stuff safe from exposure, while the foil helps retain the heat the favour. We have started exporting this product now,” explains Jaiswal.

Jaiswal says that in 2022, Jupiter developed 220 samples with a trial success rate of 90%.

Jaiswal is currently working on developing recyclable (polyolefin-based structure, homogenous structures), reducing laminate usage, and eco-friendly compostable and cost-effective laminates. “With a focus on sustainability, we have recently started printing with a water base instead of the solvent base. This not only gives us an edge over our competitors but also allows us to reduce some footprints and do some justice to the environment.”

More power to Jaiswal.

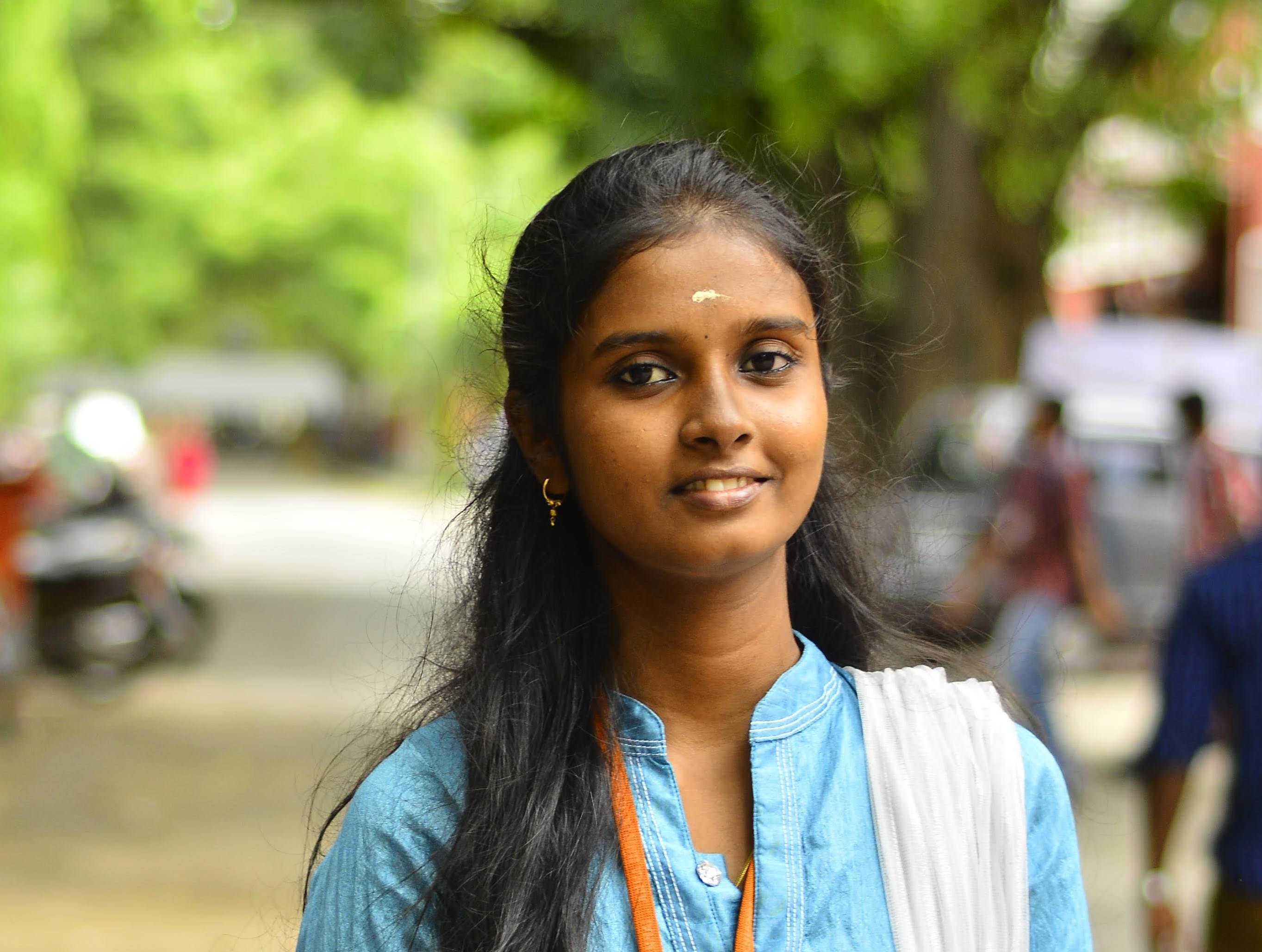

GR Shreenidhi, assistant manager – technical at ITC Printing & Packaging Business

Since her school days, GR Shreenidhi has believed in the importance of extracurricular activities alongside academics. That's why she chose a career in printing and packaging. “It's a growing industry that balances my interests and professional career,” says Shreenidhi. “I enrolled in Anna University in 2016 to pursue my engineering degree in printing technology.”

Shreenidhi had several chances to showcase her leadership skills during her engineering course. As a testament to her leadership abilities, she was bestowed with the Alumni All-Rounder Award in Imprint ‘19 at a national-level technical symposium in 2019.

Few of Shreenidhi ’s notable projects during college education include Spinach/ natamycin/ laponite nanocomposite paper: Alternative food packaging material exhibited in a poster presentation in the Indian Institute of Food Processing Technology, Thanjavur; and a paper presentation on the Preparation of paper board from waste at National Level Technology Exhibition 2019, College of Engineering Guindy, Chennai.

With more industry exposure and leadership experience, Shreenidhi was able to secure an internship opportunity at ITC. During this internship, she worked on optimising ink consumption at multiple offset printing machines. “As a result of my hard work and dedication, I received a pre-placement offer from ITC Packaging & Printing Business, one of the leading players in the packaging industry.”

From product development engineer at ITC to assistant manager – technical, Shreenidhi has worked on various opportunities ranging from creativity, innovation and sustainability.

Simran Sabharwal, co-founder, Ardour Group

Simran Sabharwal thrives in the male-dominated printing and packaging industry. With over 20 years of experience in banking, NBFCs, and media, she excels as both a contributor and team leader. Sabharwal manages B2B and B2C sales and operations in start-up and multinational corporations.

Ardour Group comprises three businesses – Ardour Pack, Ardour Flex and Ardour Polymer. Ardour Pack, incorporated in 2019, provides branding solutions and converters of all kinds of labels. Next, it expanded to Ardour Flex, providing packaging solutions and Ardour Polymers, which are manufacturers of raw packaging materials.

Using her extensive experience, Sabharwal has successfully created winning strategies for Ardour Group. She firmly believes that continuous innovation, strong technology, uncompromised quality, and impeccable pre and post-services are the key elements to carving out a niche in the highly competitive printing and packaging industry. “To achieve this goal, the company must function as an established corporate entity rather than as a promoter-driven organisation,” says Sabharwal.

Ardour's vision is to become a leading partner in success and provide a one-stop shop for all packaging requirements. Under Sabharwal’s leadership, Ardour has been recognised as one of the top 10 packaging start-ups in 2021 by The Industry Outlook.

Sabharwal is a firm believer in a customer-oriented approach and envisions fostering growth by becoming a partner in success. This has resulted in 95% plus client retention, and each client's share of wallet has increased in the last three years.

Despite facing two Covid-19 lockdowns since its inception and many more challenges that come with being a start-up in India, Sahbarwal's resilience has driven Ardour Group towards becoming a stronger and more result-oriented organisation.

The Women to Watch Awards in 2024 is powered by Manugraph in Association with TechNova and Vinsak

See All

See All