Prinova Solutions: A digital leap in Chennai’s packaging scene

From a venture capital desk to a digital press room, Atul Sonthalia built Prinova Solutions with a focus on smart labels and consumer ties

28 Oct 2025 | By Noel D'Cunha

Atul Sonthalia’s entry into printing came not from legacy or inheritance, but curiosity and timing. While working at a venture capital accelerator, surrounded by start-up energy, he was already looking to strike out on his own. What drew him to printing and packaging was the versatility: products across categories, brands of every shape and size, and the chance to collaborate with a wide network of clients doing compelling work.

The spark came from a conversation with his now business partner. That nudge led to six to eight months of deep research and learning before taking the plunge. Sonthalia immersed himself in the sector, visiting Labelexpo India and HP’s Centre of Excellence in Singapore, captivated by the customisation and speed digital presses offered. “No plates, no long waits, just quick, customisable output,” he says. Digital printing felt like a tool built for the FMCG age, a bridge between brands and consumers.

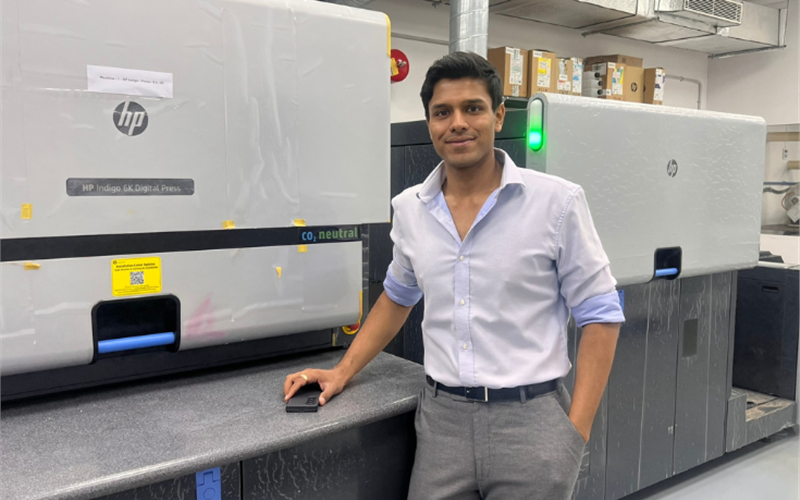

In May 2023, Prinova Solutions took shape in a rented 5,800-square-foot space in Chennai, anchored by an HP Indigo press. Sonthalia, a self-proclaimed newbie, built the plant with a startup’s scrappy mindset, learning on the fly. The press room, temperature and dust controlled, hums with precision, while a finishing line handles cutting, foiling, and more. His team of 18, including an all-rounder crew trained across machines, keeps the operation lean.

A new path with a digital press

Sonthalia’s journey to printing began far away from ink and presses. Two years ago, he worked in Chennai’s venture capital scene, studying tech startups at an incubator. Though surrounded by digital ventures, he craved building something tangible. A conversation with Sanjay Kumbhat, an acquaintance and Sanjay’s wife Sarika, now a Prinova partner, steered him toward printing. “It’s interesting,” Sanjay said, planting a seed. Sonthalia, curious, started exploring an industry he knew little about.

Sonthalia hit the ground running. The trip to HP’s Centre of Excellence in Singapore, the promise of flexibility: no plates, no cylinders, just digital precision, hooked him. “I liked the concept,” Sonthalia recalls, voice steady with conviction. Digital printing meant quick turnarounds, ideal for brands launching new products or testing specialty runs. While researching, he compared digital flexo hybrids, inkjets, and electrophotography systems, weighing liquid versus powder toner. Flexible packaging was the initial plan, but India’s crowded flexo market, thousands of units churning out low-cost labels, steered him away. “We didn’t want to be new entrants in that space,” Sonthalia says. Digital offered a niche, a chance to serve FMCG brands with small, customised runs. The HP Indigo, installed in May 2023, became Prinova’s cornerstone, chosen for its ability to print labels, sleeves, and even flexible packaging on one machine.

Sonthalia’s startup mindset shaped the plant. The 5,800-square-foot rented space houses a press room, finishing line, and pre-press team. Upstairs, an office holds his designers, though design projects were dropped to focus on production. “We were disturbing our flow,” he explains. The team, 70-80% retained from day one, reflects stability despite early hiring challenges. “As a startup, it was hard to build trust,” Sonthalia says. Now, recruiting is easier, but those first steps were a gamble.

The Indigo’s installation marked a turning point. May 2023 was when Sonthalia’s vision took physical form. He’d studied, traveled, and debated tech options, but now the press hummed in Chennai, ready to print. “I prioritised flexibility over everything,” he says, recalling his rookie logic. That choice, flawed or not, got Prinova off the ground, a newbie’s bold step into a crowded industry.

Press room precision

Sonthalia walks through Prinova’s press room with quiet pride, pointing out sensors that monitor temperature, dust, and humidity. He gestures to the HP Indigo press, the room’s centrepiece, where conditions are tightly controlled. “HP has SOPs, and we follow them exactly,” he says. The room’s parameters are non-negotiable; stray outside them, and print quality falters. Every detail, from air quality to material prep, keeps the press running smoothly.

Raw materials sit nearby, organised with care. Paper, supported films, and unsupported variants like string-free films and laminates line the shelves. “We bring material in 24 hours before printing,” Sonthalia explains. It acclimatises to the room’s temperature, a small step that prevents misprints. The Indigo’s precision demands this rigour, and Sonthalia’s team of 18 sticks to it diligently.

The press, a 13-inch model (330-mm), handles labels and shrink sleeves, with laminates as a newer focus. Sonthalia notes they print on laminates but do not seal them yet. “We are looking into flexible packaging with sealing,” he adds, eyeing 2025-2026. For now, the press room prioritises digital output, especially for brand security jobs requiring tight tolerances.

Colour management is another hurdle. The Indigo’s seven ink stations, CMYK, white, and two flexible slots, promise accuracy, but Sonthalia’s frank. “It’s not perfect.” For colour-obsessed clients, Prinova uses a spectrometer off-press and HP’s SpotMaster on-press. Shade cards set expectations: light, medium, dark. “We bind variation to an acceptable range,” he says, a practical approach that suits most clients.

The pressroom’s compactness is its strength. Sonthalia marvels at digital’s efficiency: “You don’t need big machines.” The 5,800-square-foot plant, excluding office, feels agile compared to analogue setups. Labour costs are low, one operator per machine, but ink, spares, and service contracts are steep. “It’s a trade-off,” he says, a lesson from building Prinova’s disciplined core.

Smart labels

Sonthalia sees packaging as a bridge to consumers. Prinova Solutions leans into this with smart labels, where 50%-60% of jobs use variable data printing (VDP): QR codes, serial numbers, or custom designs, for anti-counterfeiting or consumer engagement. He says, “It’s customisation, QR codes, variable numbering.” These features combat counterfeiting and strengthen brand ties, especially in pharma and cosmetics, where fakes are a rising concern.

The HP Indigo press is built for this. Its digital set-up prints unique codes or designs without pausing for plates, perfect for track-and-trace or anti-counterfeit labels. Sonthalia’s team handles one to two-crore codes monthly, each meticulously tracked. “Every code we produce is accounted for,” he says. Missing or damaged codes are destroyed, following client SOPs that differ job-to-job.

Security is a mindset, not just tech. Sonthalia ensures no samples of live security labels are kept. “They are destroyed if damaged,” he explains, nodding to the press running a sensitive job. Clients, from MNCs to startups, demand this discipline. Some send codes via databases; others email Excel or CSV files. “Everyone wants something different,” he says, but a generalised SOP covers most, with custom ones for high-volume clients.

Sonthalia’s vision extends beyond security. “Consumer engagement is what I’m selling,” he says. Smart labels let brands connect directly with buyers: scan a QR code, no app needed, and access a web app or product details. He envisions labels that surprise, like tonic water bottles with unique cocktail recipes. “Imagine five bottles, five recipes,” he muses, seeing packaging as a conversation starter.

This focus differentiates Prinova in India’s fragmented market. Digital printing’s flexibility allows Sonthalia to experiment with ideas flexo cannot match. “VDP offers hyper-personalised experiences,” he says. A brand can print 10 artworks in one run, each with unique codes or designs, without slowing the press. It is a niche that clicks with startups and MNCs, though pricing remains a challenge.

Sonthalia’s passion for engagement shapes Prinova’s path. “Packaging is not used enough for connection,” he says. Smart labels are his answer, blending security with creativity. Whether it is a pharma label guarding against fakes or a cosmetic bottle sparking buyer curiosity, Sonthalia’s VDP focus carries his belief: a label can protect a brand and tell its story, one scan at a time.

Finishing line balancing analogue and digital

Sonthalia calls Prinova’s finishing line its Swiss Army knife. He points to a single-station flexo unit with semi-rotary die-cutting that handles foiling, varnishing, lamination, sheeting, and in-mould labelling (IML). “It does a bit of everything,” Sonthalia says, noting its conveyor and static removal features. Paired with a flatbed die-cutter for hot foil samples and a slitter-rewinder, it completes Prinova’s post-press set-up.

Versatility brings challenges. Sonthalia admits the analogue finishing line clashes with the digital HP Indigo press. “Some flexo issues creep in,” he says. Dies slow things down. Digital printing skips plates, but die-cutting needs dies, which can take a day. “You print fast, then wait,” Sonthalia says, describing a bottleneck that undercuts digital’s speed advantage.

Substrates complicate matters. Sonthalia explains clear-on-clear films cannot use flatbed dies because they cut too deep. Prinova uses pricier magnetic semi-rotary dies instead. “Clients see no plates, but balk at die costs,” he says. A digital plotter, recently invested in but not yet arrived, aims to fix this by cutting dies digitally to match the press’s agility. “It’ll resolve lead times,” Sonthalia hopes, eyeing a smoother flow.

The flexo unit’s strengths shine elsewhere. Sonthalia notes it applies spot UV or foiling, though plates are needed, adding prep time. For IML, the sheeter and conveyor streamline output, but each job requires adjustments. “It is a challenge the first time,” he says. His team saves SOPs and parameters for repeat jobs, pulling them up to avoid relearning curves. “We have covered most materials now,” he adds, sounding seasoned.

Labour remains lean. Sonthalia cross-trains operators from rollfed to flatbed, and slitter to sheeter, to minimise downtime. “If someone is out, we are covered,” he says. Unlike the Indigo, where HP certification limits flexibility, post-press allows this all-rounder approach, keeping Prinova nimble with its small crew.

Maintenance is uneven. Sonthalia says the Brotech finisher faces service issues, prompting thoughts of replacement. “It has been a challenge,” he admits. The Sankit cutting machine, an Indian brand, holds steady, but all machines face downtime, typically once a month and usually fixed in hours.

Sonthalia is planning digital embellishment next. “The day we go fully digital on finishing, it will be as easy as printing,” he says. Digital die cutting is a start; digital foiling or varnishing could follow. These upgrades align with Prinova’s digital-first ethos, reducing analogue bottlenecks. “We are getting there,” Sonthalia says, nodding to his start-up’s iterative growth.

Future growth with consumer focus

Sonthalia’s sights are set on expansion. Prinova Solutions’ rented space has outgrown its Chennai base. “We are out of space,” he says, planning a Greenfield move by 2025 or 2026. A plot is secured, and talks are underway to build a larger facility, spacious enough for new machines and bigger goals. “Any further expansion happens there,” he adds, voice firm with purpose.

Consumer engagement fuels his plans. Smart labels with variable data printing (VDP), including QR codes and custom designs, are Prinova’s niche. Sonthalia wants to deepen this. “A label can tell a story,” he says.

Sonthalia’s vision remains consumer-centric. “Every package should start a conversation,” he insists. Whether through smart labels that verify authenticity or QR codes that share recipes, he sees packaging as the final and most personal touchpoint between brands and buyers.

To read the complete feature, subscribe to our magazine and get your hands on the latest edition (October 2025) of PrintWeek magazine

See All

See All