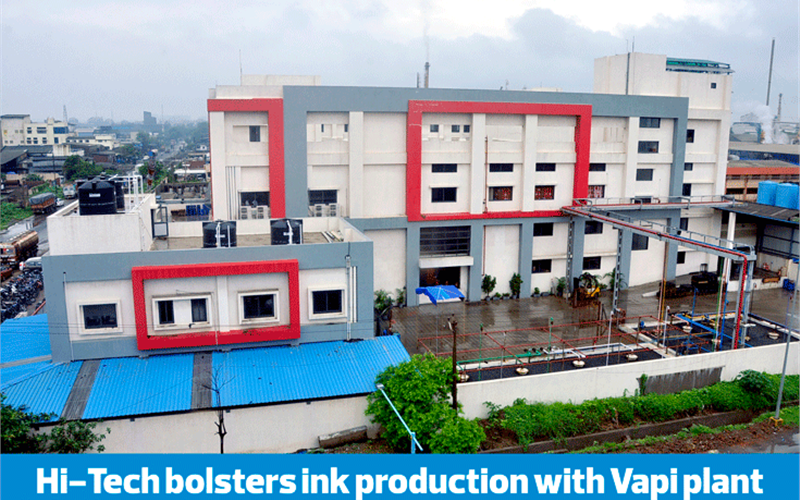

Hi-Tech bolsters ink production with Vapi plant

The new facility, which is three times the size of its existing plant, has been set up keeping in mind the growing demand for printing inks. Abhishek Muralidharan of WhatPackaging? speaks to Hi-Tech Inks' Karan Mahajan about the investment

07 May 2021 | By Abhishek Muralidharan

Hi-Tech Inks has opened its new factory, an ambitious project kick-started in early 2019, in Vapi. This will bolster its ink production capacity and enable the company to tap into new markets.

With a constructed area of about 1,00,000 sqft, the newly-built facility has an installed capacity of 1,600 MT, which can further be increased up to 2,200 MT as required. The factory is almost three times the size of its existing plant.

Speaking about the investment, Karan Mahajan, managing director, Hi-Tech Inks tells WhatPackaging?, “Let’s just say that the investment was large enough for not wanting me to invest for quite a few years going forward.”

Mahajan says the plant was designed keeping in mind the future demand for printing inks, without sacrificing the safety aspect. Pointing out a fire accident that took place in the past, he said the new facility is equipped with “state-of-the-art safety parameters”.

“Simultaneously, I wanted to provide a very comfortable and spacious environment for my team members. These things do not come cheap; especially in the location, we are in right now. We are currently employing close to 200 people, which includes about 65 contract workers,” Mahajan adds.

Mahajan: The plant is equipped with state-of-the-art safety parameters

Safe production

Hi-Tech Inks manufactures all types of solvent-based inks to serve the gravure and flexo printing demands. The company is also geared up to segregate production between the conventional toluene-based inks and the environment-friendly non-toluene inks.

Mahajan divulges more on the product safety norms at the factory: “In solvent-based factories, every product requires safety norms to be followed, as the solvent itself is the most hazardous product. Based on this, we have installed state-of-the-art safety equipment, which includes fire alarms, smoke detectors, water sprinklers in designated areas and a 3,00,000 litre water tank and foam generating units for fire-fighting.

“We also conduct regular fire and safety training for all our employees and have designated teams within the factory responsible for each area. Regular checks of earthing pits are also done periodically.”

Apart from India, the company has been operating in Sharjah, UAE. It has a warehousing and blending facility, which services the entire GCC and the Middle East. It also caters to most of Africa from its Sharjah office.

Mahajan believes that the markets outside of India have definitely been affected more than India due to the ongoing pandemic. “The markets have been much slower with demands also being on the lower side,” he adds

The second wave

The second wave of the pandemic struck India at a time when the country was limping back to normalcy. “Honestly, you only realise the seriousness when it comes knocking at your doors or starts affecting your near and dear ones,” Mahajan expressed.

He says the real impact of the second wave started being felt in April, and the cases spiralled out of control, burdening the medical infrastructure. However, it did not affect the factory operations in a big way.

“We have been following the necessary safety and Covid-19 related protocols for over a year now and I think that has helped in keeping things in check,” he adds. “Yes, there have been a few cases that have come up, but if you take the necessary precautions and protocols, you can curtail the spread of the virus. Our employees have been very supportive and understand the seriousness of this virus and thus the self-awareness also makes a huge difference.”

The newly-built facility has an installed capacity of 1,600 MT which can be increased up to 2,200 MT

The company followed the standard Covid-19 protocols such as sanitisation of vehicles and work spaces, checking body temperatures, frequent oximeter checks, social distancing, and WFH whenever possible. Apart from that, the company also tweaked its shift timing and the number of people in each shift to maintain distance between each employee while working.

“We also added a health coverage policy for all our employees last year before the Covid-19 pandemic struck and that has been hugely appreciated by the employees,” claims Mahajan.

Supply chain management

Mahajan points out that managing the supply chain has been a huge battle for everyone and “we are no different”. “Unfortunately, there have been a series of unprecedented events, which coupled with the pandemic, created further challenges,” Mahajan states.

However, he feels that the company has not done anything differently. “We have kept the same strategy for procurement and stock planning that we used to maintain pre-Covid. I don’t think panic buying and over-stocking help beyond a certain point and that is then a reason to start having cash management issues,” he says.

“I would be lying to say that stock planning has been easy, it’s been very stressful and probably needs to be attended to multiple times in a day. But, I feel this is also an experience that the team will learn from and help them get prepared for the future,” he adds.

The new plant is set to bolster Hi-Tech's production capacity and enable it to tap new markets

Normalcy is far

“It’s still early to start thinking of recovery,” says Mahajan, adding that total recovery is very far from our reach. “Unless and until the entire world is free from this, recovery is not possible.”

Mahajan remarks that the industry is heavily dependent on imports and the trade gets challenging as per the situation of the exporting country. “So far, it seems that vaccination is helping to some extent and the entire globe needs to focus on vaccination drives so that we could stop the third or fourth wave from coming,” he adds.

“For the most part we have handled the situation to the best of our ability,” says Mahajan. “Like any entrepreneur, you always feel there is the scope of improvement, but overall, I am quite satisfied with how my team has handled the entire situation.”

However, Mahajan is disappointed by the current situation of the country. “To see people suffering the way they are is cruel and difficult to watch,” he says. “Let’s hope that the sufferings come to an end soon and start focussing on positive things ahead of us. Until then, stay safe and stay strong.”

See All

See All