Eleven days of the best of print and packaging - The Noel DCunha Sunday Column

On 28 May 2024, Drupa will open its doors to the print, paper, and packaging industry. With 18 halls and 1,40,000 sqm of space, the 1,400 exhibitors are gearing up to showcase their offerings. While the exhibitors are preparing their showcases, some have already done so.

In this Sunday Column (Part I in the Drupa Series), we share highlights of 19 companies and their products at Drupa.

16 Mar 2024 | By Noel D'Cunha

Indian visitors to Drupa will have an opportunity to witness industry-changing exhibits – billed as the event “to create the future”. Noel D'cunha and Rahul Kumar brings details of some exhibitors who have shared the details of their exhibit at the show.

Barbieri Electronic

Barbieri Electronic, the colour measurement devices specialist for digital large-format printing, will introduce its new spectrophotometer Spectro Swing QB for colour measurement in professional digital printing.

The Spectro Swing QB is a versatile tool that offers automated reflection and transmission measurements for flexible and rigid materials up to 1.2 mm thick. It is designed for industries working with non-textured cardboard, flexible non-textured materials such as paper and film, and labels.

Incorporating Barbieri QB technology, Spectro Swing QB enables precise colour measurement, calibration, and profiling of digital printing systems. Its automated reflection and transmission measurements make it a perfect fit for a wide range of materials, such as cardboard, paper, film, and labels. Its colour management process helps companies improve colour accuracy and enhance the quality of their products.

Baumer HHS

Baumer HHS, with its slogan for Drupa 2024, “Leaving an innovation fingerprint where others leave a carbon footprint,” is not just focusing on innovation but also on sustainability. The company's five areas of focus, including sustainability, digitalisation, customer care, innovation, and vision, are all under the theme “Yesterday’s pioneer—today’s benchmark”. This approach is why Baumer HHS's customer base is growing in the global packaging industry, as they can trust in the company's commitment to the environment.

Baumer HHS, a company with long-standing expertise in the industry, offers customers added value on all levels with its innovative solutions in industrial gluing. The company has been producing pioneering innovations for decades, particularly in the folding carton and print finishing segments. This track record is a testament to Baumer HHS's commitment to delivering high-quality solutions to its customers.

At Drupa, the company will showcase its sustainable approach to packaging and demonstrate its innovative solutions, including the revolutionary Side Seam Gluing Solution for straight-line boxes, the Xcheck DCM for monitoring product mix-ups in sheetfed die cutters using 2D codes, and the solution for securing pallet loads and controllers.

Visitors will also witness some world premieres at the Baumer HHS stand.

Canon

Canon is set to launch a new industrial-scale label printing press called Canon LabelStream LS2000 at Drupa 2024 in Düsseldorf. This water-based inkjet press is capable of printing at a speed of 40/m min and can print CMYK and white on various self-adhesive substrates, including synthetic and coated paper and film. It has a maximum printing width of 340mm and features a new 2400 x 1200 dpi printhead with an ink circulation mechanism to minimise nozzle-clogging and enhance the printhead's lifespan.

The ink set used in this press is designed to meet food safety standards. It is said to be the optimal solution for label converters looking for a digital press that can meet the demand for shorter runs of diverse, self-adhesive labels in industries such as household and personal care, where tight deadlines are a norm. High-density, water-based polymer inks have been developed specifically for printers, containing highly saturated pigments for a wide colour gamut. The inks form a thin layer on the substrate, reducing light scattering and optimising colour accuracy. They are described as being "almost imperceptible to the touch" and aim to maintain the look and feel of the printed material.

This press can use high-opacity white as an undercoat for other inks, making it compatible with transparent film media. Printhead maintenance, quality control, colour measurement, and adjustment are all automated processes for the Canon LabelStream LS2000. The digital front end of the press aims to offer tight workflow integration, ease of use, and efficient operations.

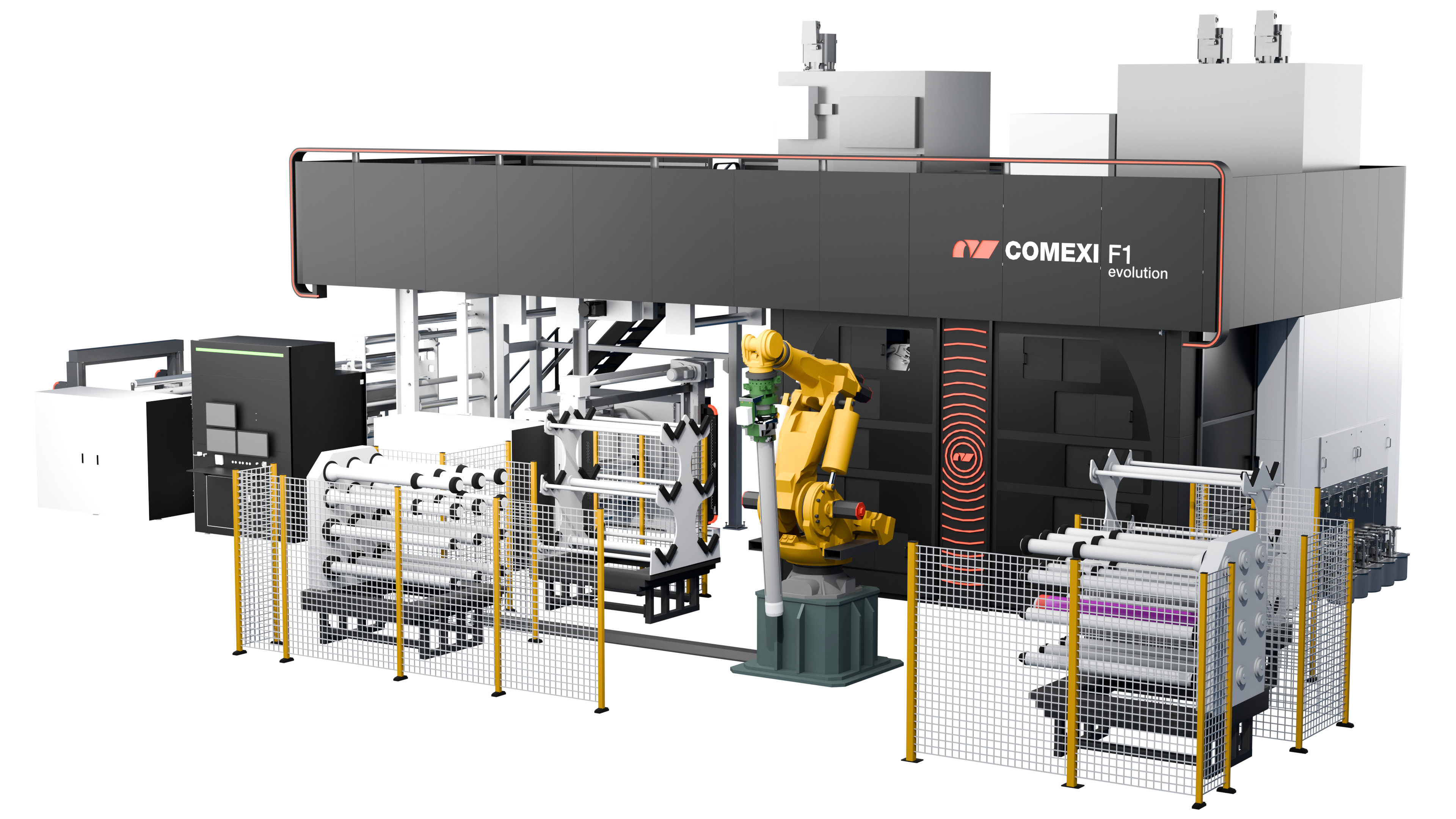

Comexi

Comexi will premiere a new flexo press. It is set to captivate the industry with the new F1 Evolution press launch at Drupa 2024. With a speed of 600 m/min and a printing width of up to 1690mm, this innovative press is designed to revolutionise how you print, with developments of up to 1260mm.

The F1 Evolution is capable of printing at a speed of up to 600m/min and a width of up to 1690mm with excellent robustness and drying capacity. It can be equipped with a robotic arm for sleeve and anilox changes and has GeniusTech automation for initial setup, adaptable drying, and fast cleaning.

According to Comexi, the machine is ideal for medium and long jobs and sectors where each print's profitability is crucial, such as hygiene products and food packaging printed on mono-materials without further processes.

Drupa 2024 will be a platform for Comexi to unveil a plethora of new solutions. Alongside the F1 Evolution, it will expand its range of offset presses, introducing a broader offset CI model for flexible packaging and paper markets. Comexi will also launch a colour closed loop system for precise colour control without print marks, digital printing solutions for enhanced profitability and sustainability, and the S2 DT slitter, equipped with dual laser heads and an inspection system for precise micro-perforation control and measurement. Get ready for a new era of printing.

Duplo

Duplo, a leading manufacturer of printing and finishing equipment, has launched its latest saddle stitching system, the iSaddle Senshi. The kit will be demonstrated at Drupa.

This powerful machine is designed for publishing, marketing, and commercial printing operations. Equipped with end-to-end automation, it easily handles complex jobs and short runs, making it a force to be reckoned with in the industry. Its heavy-duty stitching ensures durability, while its flat-to-finished book production speed of up to 5,050 A5 booklets per hour is unparalleled.

With the iSaddle Senshi, Duplo has raised the bar for productivity and efficiency.

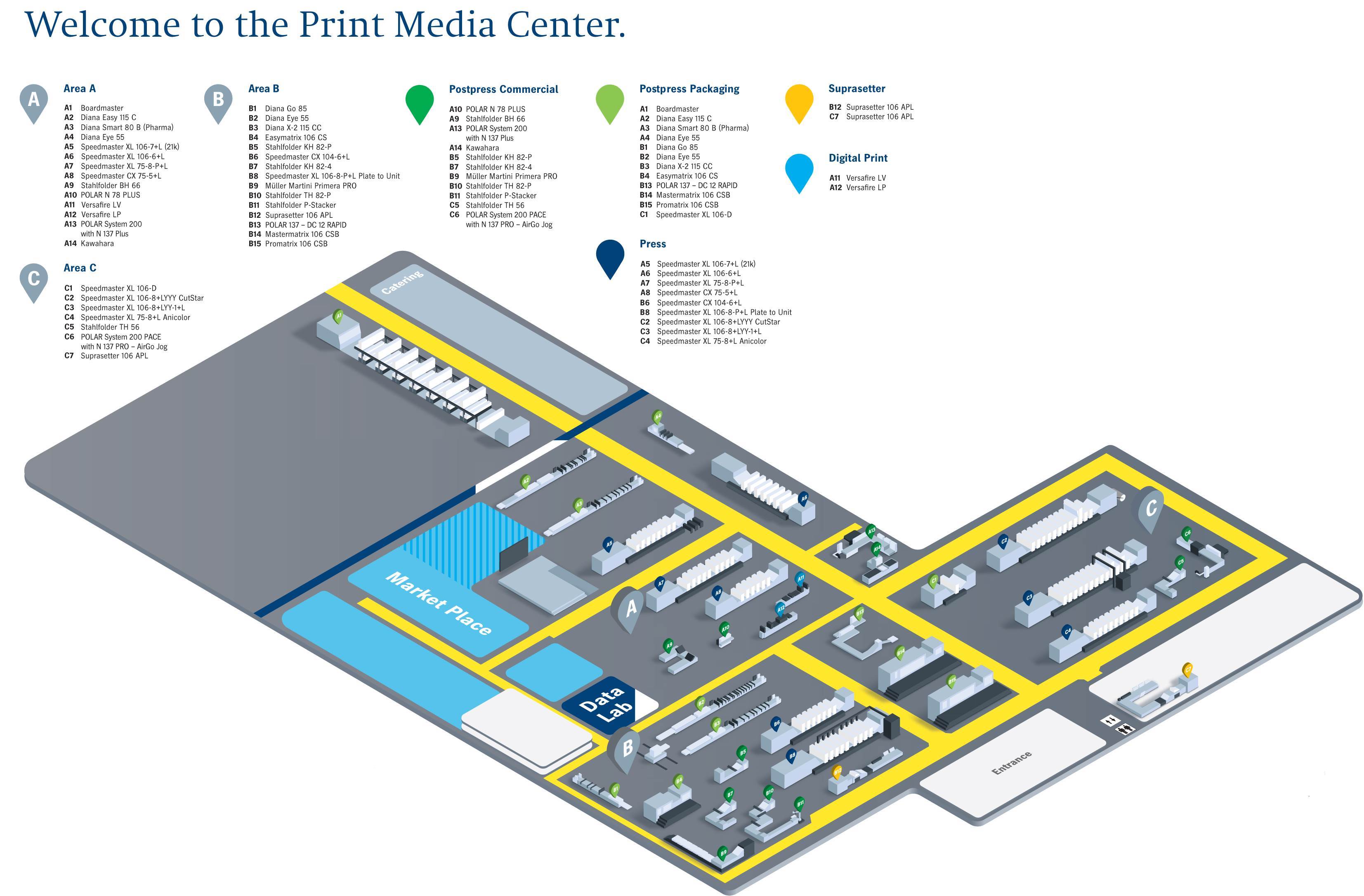

Heidelberg

Heidelberg will present a unique end-to-end, automated workflow for industrial packaging production designed to enhance competitiveness under cost pressure and changing conditions. This innovative solution includes robotics and automation in post-press, the Speedmaster XL 106, and the new Boardmaster with Intellimatch for high-volume packaging printing.

Heidelberg offers commercial and publishing printers a comprehensive end-to-end workflow featuring Prinect. This solution, which includes plate imaging, plate feeding, CutStar, and collaborative robotics in post-press, offers numerous benefits, including (specific benefits).

The Experience Center presents AI-based analysis tools, intelligent assistance systems, online services, and sustainable production solutions.

During Drupa 2024, attendees can visit the Print Media Center in Wiesloch-Walldorf for a range of interactive experiences. These include exploring the Print Application Gallery, Data Lab, and product tours, engaging in personal discussions with Heidelberg experts, and savouring the factory tours.

HP

Between 2016 and 2024 (Drupa 2020 did not take place), HP revamped its entire Indigo portfolio, including launching Series 5 products such as the 100K, its sibling 15K, and the V12 label press, among others.

At Drupa 2024, HP, supported by a comprehensive partner ecosystem, will spotlight eight automated production lines capable of handling 80 jobs and 25 different applications in the industrial print segment. In the large-format business, too, expect HP to showcase new solutions that meet the print service providers' high-level demands and optimise the work process.

Additionally, HP has announced that it will share actions to deliver on its commitment to reduce emissions by 50% by 2030, decarbonising print and packaging through technologies and inventive collaboration.

Intec

Intec's new B3-plus digital die-cutter, the ColorCut FB580, is a powerful machine that has all the features of bigger cutters. It can cut and crease in a single operation, allowing users to produce prototypes and light production runs easily. The device is highly specified and can cut a wide range of materials, from rice paper and synthetics to folding box boards, labels, and types of vinyl.

The ColorCut FB580 has a maximum substrate area of 440x580mm, and the operator can adjust its three-speed forces to accommodate intricate cutting or cutting straight lines fast. The software features QR codes, page marks, and a reverse side-cutting feature that reads the sheet edges. The device has a "no wires" option for repeat jobs that can be loaded via a USB stick.

Kodak

At Drupa 2024, Kodak will showcase groundbreaking continuous inkjet technology and solutions for traditional print, all designed to help printers maximise their profitability as the industry evolves.

New Kodak products, systems and technologies will be on display at Kodak's booth in Hall 5 as well as at the booths of industry partners. As a pioneer in technology innovation, Kodak will demonstrate its unwavering commitment to being the one-stop partner for printers' digital and traditional production needs.

Koenig & Bauer

German print and packaging equipment manufacturer Koenig & Bauer has announced their expected expenditure for the Drupa event, which is likely to be in the eight-digit range. As the world's population continues to grow, the middle class is also expanding, increasing demand for high-quality packaging. This has led to a need for more individualised, diverse, and high-quality packaging.

As a result of these trends, printing technology is becoming more sustainable, digital, and modular. This allows for more agility, cost-effectiveness, and efficiency, providing more possibilities for businesses. During the Drupa event, Koenig & Bauer will showcase a complete packaging workflow with daily live shows on their stand. Visitors will have the opportunity to experience the latest innovations in digitalisation and modularisation, including real-time production press data available through the cloud and AI-based productivity enhancement.

In the Touchpoint Packaging section, visitors will learn how packaging is conquering the metaverse, while the Touchpoint Sustainability section will feature an energy management system to reduce and optimise energy usage during production. Koenig & Bauer's printing technology, which includes offset, digital, flexo, and specialty printing, can be used on almost all substrates and is the right solution for businesses looking to meet the growing demand for high-quality packaging.

Komori

Satoshi Mochida, president and representative director, Komori

Komori, the Japanese manufacturer, is set to unveil a new environmentally friendly offset press and a next-generation digital printing machine at Drupa in May. The company celebrated its 100th-anniversary last year and defined its purpose for the next century as "Delivering Kando beyond expectations by contributing to society with print technology."

Komori has alliances with Landa for the Impremia NS40 B1 digital press and with Konica Minolta for the IS29S B2 format UV inkjet. Additionally, its presses have been updated with fresh features to reduce environmental impact, including improved controls, automated quality inspection, robot logistics, and energy-saving and paper waste reduction technologies.

At its 1,500sqm booth in hall 15, Komori plans to showcase a "seamlessly connected" smart factory that links MIS, pre-press, press, and post-press. Its KP-Connect cloud-based process management system is at the heart of the setup. The exhibit will feature Autonomous Mobile Robots (AMR) and MBO's CoBo-Stack collaborative robot.

MBO, which Komori acquired in 2020, also has its own space in the Postpress Alliance, which is adjacent to the main Komori space. The alliance includes Hohner, Bograma, Baumann, and NBS. According to Komori, the linkages of equipment to be shown in the Alliance area embody Komori's "open innovation concept."

Konica Minolta

At Drupa 2024, Konica Minolta is set to make a significant impact with its impressive stand occupying six inter-linked areas and two floors in Hall 8b. The stand, located at A40-1/A40-6, will be one of the largest at the event, showcasing the company's vision for the transformation of the print room.

Konica Minolta will also unveil multiple European premieres at the event, offering visitors an exclusive preview of the latest and most innovative printing solutions. The company will focus on labels, packaging, and embellishment, providing printing companies from around the world with insights into the benefits of digital print automation, end-to-end production workflows, and world-class software solutions.

Konica Minolta and MGI will collaborate to help visitors understand how they can leverage these technologies to enhance their business operations and achieve greater efficiency and productivity. With its commitment to innovation and customer satisfaction, Konica Minolta is poised to make a lasting impression at Drupa 2024.

Kyocera

Kyocera Document Solutions Europe is set to unveil its newest inkjet commercial printers at Drupa. The Taskalfa Pro 55000c and the TASKalfa Pro 15000c will be on display.

The TASKalfa Pro 55000c was introduced to the US market in 2023, while the Taskalfa Pro 15000c is making a comeback at Drupa. The Kyocera team aims to showcase the power of inkjet technology and these devices' small footprint.

The Taskalfa Pro 55000c, an inkjet technology, boasts energy efficiency and minimal maintenance, setting it apart as an ideal choice for the graphic arts space. Its media versatility opens a world of creative possibilities, enhancing productivity and unleashing your artistic potential. As Kyocera's inkjet portfolio expands, these two machines, particularly the Taskalfa Pro 55000c, take centre-stage at Drupa 2024, promising to captivate and inspire.

Kyocera experts will be on hand at Hall 8A/C20, ready to delve into the devices' various applications and address any queries about Kyocera's innovative technology.

Pratham Technologies (Indian exhibitor)

At Drupa, Pratham has booked a 188-sqm stand. In the field of insert-outserts, Pratham claims that it is on par with global leaders. But at Drupa, Pratham will be showing a robotic tray packaging machine. It will be a first-time innovation, perhaps, and it could be the first in the world, claims the company.

Pratham did not disclose the model name but said it is an end-of-the-line packaging system. Today, in Europe and the USA, there is a human resource crunch. It’s become one of their main headaches. Pratham saw this as an opportunity to develop an automatic machine that could replace human intervention.

Besides, the company will also launch the Superfold pile feeder PF 53, an automatic outserts and inserts folding machine. The outserts feeder machine is specially designed for handling think folding applications, while the insert is a high-speed feeder machine designed for handling Bible and coater paper.

Ricoh

Ricoh has revealed more information about its plans for the Drupa expo, including expanding its creature-based product names. The company's theme for the event is 'Henkakuverse', a Japanese term for transformational innovation, described as "a virtual production environment".

The company will showcase its Pro Z75 B2 perfecting inkjet press, also known as the Dragon, which will make its European debut at the event. The Dragon can print at 4,500 sph in straight mode or 2,250 sph for duplex/perfecting printing.

Ricoh will also show new sheetfed and webfed devices. Ricoh's new flagship webfed inkjet press, the Pro VC80000, which has AI capabilities among other features, will be launched at the event and is now known as 'the Harpy Eagle'.

Ricoh's new sheetfed digital presses, the 135ppm Ricoh Pro C9500 and five-colour Pro C7500 device have been named 'the Jaguars' after the big cat.

The company will also showcase new automation, workflow, and software tools and its Professional Services consultancy offering.

In addition, Ricoh's booth in Hall 8A will feature an immersive theatre experience at the centre of its stand, showcasing the Henkakuverse and its opportunities in a spectacular way.

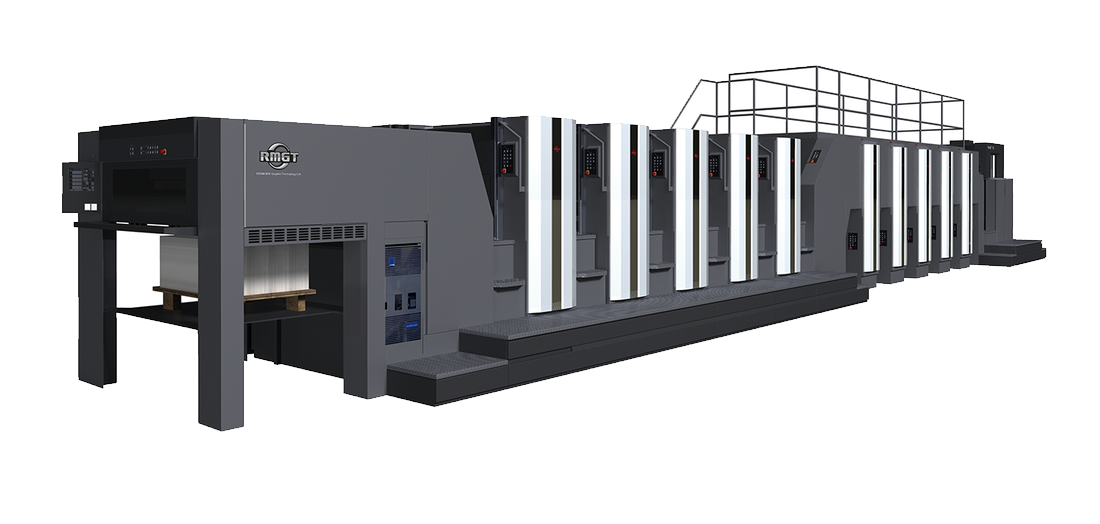

RMGT

RMGT will debut two new presses at Drupa

RMGT will exhibit at Drupa with the theme "Assist your potential with technological expertise and constant innovation." The focus will be on "Increased productivity for commercial printing" and "Further automation for package printing."

On display for the commercial print market and the packaging market will be the 970PF-8+LED, RMGT's eight-colour convertible perfector, available in straight configurations for up to eight colours and perfectors for up to 10 colours. The 1060LX-6+CC press is a 1,060 mm format six-colour offset press with a coating unit, extended delivery, and a printing speed of 17,100sph. These advanced presses feature new-generation skeleton cylinders and the most comprehensive automation packages available, resulting in higher operating rates and speedy job changeovers.

Screen

Screen has announced the completion of a new roll-fed digital inkjet press for commercial printing, direct mail, and publishing printing markets. The kit will be showcased at Drupa.

The newly developed Truepress Jet 560HDX has several print modes, allowing it to handle paper widths of up to 560mm at speeds of up to 150m/min with a maximum resolution of 1,200dpi.

The Truepress Jet 520HD, 520HD+, and 520 HD AD printers with the Truepress SC and SC+ ink sets will continue to be available. The Truepress Jet 560HDX is fully compatible with Screen's innovative Truepress ink SC2, a versatile high-optical-density ink set that allows direct printing onto offset-coated papers without any pre-treatment, opening up a world of possibilities for your printing needs.

The press is also equipped with a new fast-start operating system that ensures seamless integration of all internal hardware and software and pre- and post-finishing equipment.

StudioRip

At Drupa, StudioRip will showcase two main products: StudioRIP, their RIP and pre-press workflow software, and StudioRIP DTP, their inkjet CTP system.

The StudioRIP software and inkjet CTP system have been on the market since 2000 and 2014 respectively but are now being updated. StudioRIP is a RIP and workflow software used in the pre-press industry, covering a wide market: it drives CTP machines for offset and flexo, creates pre-press films for flexo, screen printing or other UV-exposure based technologies, prints proofs, drives inkjet printers for generic colour printing, and has a wide range of features like imposition, trapping, and ink duct control.

StudioRIP DTP is an inkjet CTP system which creates conventional aluminum offset plates using inkjet printers. While its quality is very similar, its price is a fraction of the conventional laser CTP machines. With the StudioRip software, the company will utilise the existing stand of the Epson SureColor T5405 printer and attach its plate positioning system to it. The UV exposure will be a separate, optional module, and the plate processor will be fully automated. These systems will be controlled through 3.5-inch touch screens with a user-friendly graphical interface.

Xeikon

Xeikon is all set to showcase its latest innovations at Drupa 2024.

According to Xeikon, it understands that printers and converters are now looking for sustainable solutions that can help them make future-proof investments. Therefore, Xeikon has invested significantly in developing de-inkable print technologies, environmentally friendly LED inks, innovative toner formulations, and toner compositions that use over 60% recycled content.

At Drupa, Xeikon will demonstrate its unique solutions for four key markets: Flexible Packaging, Corrugated packaging, graphic arts, and label printing.

In the flexible packaging market, Xeikon's Titon solution ensures food safety even when printing on paper-based flexible packaging, meeting stringent temperature, chemical, and mechanical resistance requirements.

In the corrugated packaging market, Xeikon's Idera technology delivers a food-safe solution within the post-print corrugated environment.

For graphic arts, Xeikon Sirius offers cost-effective technology for medium-run commercial print.

In label printing, Panther (UV Inkjet) and Lion (dry toner) technologies excel in speed and quality, offering two complementary processes that deliver sought-after sustainable benefits.

If you have an update about the Drupa show, please write to noel@haymarketsac.com or rahul@haymarketsac.com

See All

See All