Mumbai's Inndus Cards & Gifts boosts production with Esko Kongsberg X

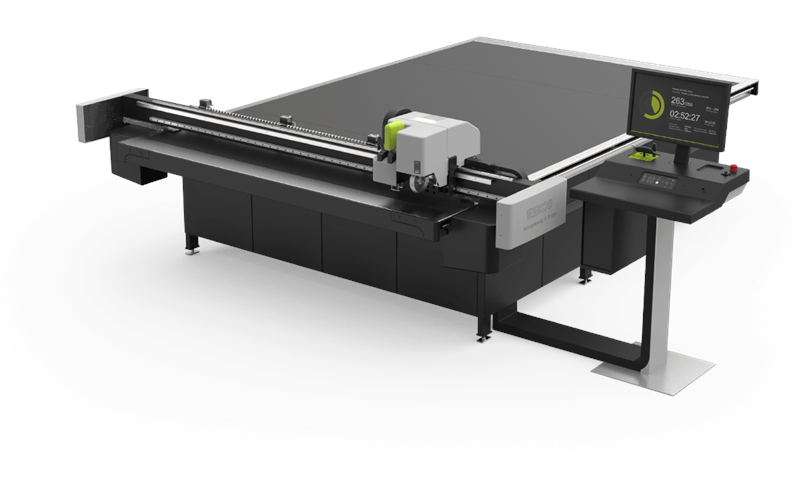

Mumbai-based digital printing company Inndus Cards & Gifts has expanded its offering with the installation of latest Esko Kongsberg digital finishing equipment to enable the company to move into in-house serial production.

02 Apr 2020 | By Aultrin Vijay

Based in Goregaon, Inndus Cards & Gifts caters to corporate customers in the financial services, hospitality, information technology, and eCommerce sectors. The company prints, manufactures, and supplies a variety of printed and fabricated items such as paper bags, presentation folders, sun board POS cut-outs, boxes and stickers. As part of its growth plans, Inndus purchased and installed an Esko Kongsberg X cutting table to extend its product range capabilities.

Shailesh Sharma, founder and managing director of Inndus Cards & Gifts said, “The main reason for buying the Esko cutting and creasing table was that we wanted to increase the variety of products we were producing, by leveraging our expertise in the digital printing business.”

“Since we do a lot of work where the quantities of specially-shaped and fabricated products range from just 10 through to 300 finished units, we wanted a technology that would help us bypass the conventional die-punching process. The digitally-driven Esko sample-maker made perfect sense,” Sharma added.

Inndus currently uses its Xerox Versant 80 and IGen 4 presses for digital printing for short-run and personalised products and has other wide format and flatbed inkjet printers for larger products. Before the commissioning of the Esko Kongsberg X table, Inndus was using a China-manufactured table for sample making but not production, not even for its short run work.

“When we decided to go beyond just sample making and into in-house serial production, we opted for Esko,” said Sharma. “Esko is a pioneer in this field, with a fantastic and powerful support system in India, which we really appreciate.”

He asserted that the most significant advantage the Esko solution offers is that it helps printers add a great deal of value to their products, which in turn gives them the confidence to charge a premium for their products.

“The fact that the precision of the Esko table helps us make our products look different and better from the other run-of-the-mill products on the market is what gives us confidence. If you fully and optimally utilise the Esko table, you can do wonders with it,” Sharma added.

For its print and fabrication work, Inndus is mainly processing sun board, kappa board, paper, PVC, and rigid sheets. The print shop is currently running the Esko Kongsberg X for about eight hours every day.

According to Sharma, investing in an Esko Kongsberg table is critical for any printer who has multiple digital printing machines and produces short run products that require creasing, folding and cutting in unique shapes. He argued that a robust finishing department is an essential ingredient for a printer’s success.

“In my opinion, a digital printer who has two or three presses should invest in a Kongsberg table instead of going for another press. The Esko Kongsberg X will turn out to be a better revenue generator. Also, it is always easy to outsource printing jobs but very hard to outsource finishing jobs. A robust in-house finishing department gives you control over both quality and your delivery schedule,” he said.

However, Shailesh cautioned that in order to fully exploit Esko digital finishing solutions, a printer should have an excellent design department. “For the Esko table to work like a charm, you need to have a strong design team as well!” he said.

See All

See All