JK Fine Prints expands its label print business with a third Gallus EM 280

The Mumbai headquartered label specialist, JK Fine Prints has installed a third Gallus EM 280 as it plans to scale up its capacity from the present six-lakh sqm to one-million sqm per month. The latest flexo press joins the two other Gallus EM 280 presses at JK’s two-floored plant in Taloja, close to Navi Mumbai.

19 Nov 2018 | By Noel D'Cunha

The first Gallus EM 280, a seven-colour press was installed in 2006, while the second was installed in 2013. Like the 10-colour EM 280, the latest is a six-colour equipped with web guide, servo tension, corona treater, infeed and outfeed full servo, all units with active antistatic bars, chilled drums, auto ink pumps, two die-stations, two cameras, auto-register and plate mounter among others. It also has India’s first IST MBS 7 UV system.

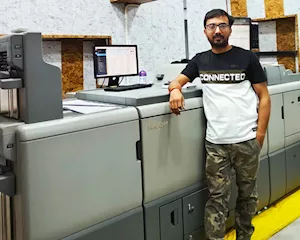

“We were full, running the two presses 24-hours to meet the requirements of our existing clients. But there were potential clients in the pipeline whom we could not cater. We don’t add new clients unless we are absolutely sure we can serve them,” said Himanshu Kapur, one of the three directors at JK Fine Prints who manages the company’s plant at Taloja.

Kapur’s cousins Karan and Rahul manage the company’s marketing and sales.

Explaining the rationale behind opting for a six-colour press, Kapur, said, “We bought the machine so that it can run CMYK plus a varnish and a special colour. Close to 64% of our jobs are six-colour, which will be pressed onto the new kit, giving us more time to concentrate on more difficult eight-and ten-colour jobs.”

JK Fine Prints supplies labels predominantly for the pharmaceutical, food and beverage, lubricant, automobile, FMCG and personal care, and has opted for the narrower 11-inch format press, bucking the trend where labellers are looking for wider 14- and 17-inch flexo presses. “It’s all about economics, and the benefit is either in time or money. We work on a set size and a line of similar press format means whichever press finishes first takes up the next job. Ideally, all three keep on rolling.”

Besides the three flexo presses, JK is equipped with two letterpress label machines, three Omegas, one hot stamping machine, fully automatic core cutting and a host of finishing equipment.

JK Fine Prints was established in 2006 by the Kapurs under the guidance of Kapur’s father, Surendra and uncle, Jatindra.

Fact file

- Established in 2006

- Speciality Self-adhesive labels

- Location Plant in Talojo

- Equipment Three Gallus EM 280 flexo press, two letterpress label machines, three Omega inspection system and a host of finishing equipment

- Employees 55

- Turnover Rs 35-crore

See All

See All