Vasai’s Mayura Offset turns to Bobst Accubraille to expand converting options

Mayura Offset, the packaging specialist from Vasai, a print hub around 60kms from Mumbai had started its research to overhaul its folding-gluing equipment during Drupa 2016, which ended in the installation of Bobst folder-gluer closer to the end of 2020. The multipurpose Bobst Expertfold 80 A2 installed in October 2020, includes the Braille attachment, Accubraille.

02 Aug 2021 | By Noel D'Cunha

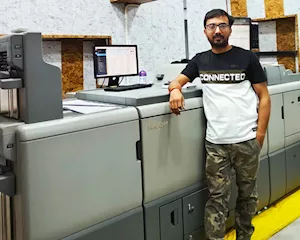

“We had the older Bobst Media 68 machine previously and really required an upgrade due to a need to do a bigger variety of cartons as our business grew with time,” said Piyush Sinha, managing director at Mayura.

Mayura’s 1996 make Bobst Media 68 capable of running at 300m/min, had options of converting lock-bottom carton jobs but not all section and patterns were possible. “For example, the injection cartons and bigger boxes,” said Sinha. The Media 68 was limited and for more standard sizes and we had to up our game in finishing and converting.”

Established in 1987, Mayura began as a small letterpress unit and evolved to become a sizeable packaging converter. From a turnover of approximately Rs 2-crore as a letterpress unit to approximately Rs 70-crore today, equipped with four Heidelberg multi-colour presses and a single-colour press used for varnishing, a Mitsubishi two-colour perfector; Bobst die-cutting machine, an Acme folder-gluer, H+H outsert folding machines, and a Pratham leaflet folding machine, the company has made stunning progress, specialising in cartons, inserts and outserts for the pharmaceutical industry.

The Bobst Expertfold can produce produces boxes in different styles using a range of materials at a speed of up to 450 mtr/min. “It is easy to operate, delivers both striking productivity and boxes of unrivaled quality. It also allows us to simultaneously carry out other inline processes such as Braille embossing with Accubraile, making it ideally suited for the pharmaceutical and cosmetic markets.”

The company’s pharma clients include Cipla, Emcure, Glenmark, Intas, L’amar HealthCare, Macleods, Mylan, Piramal, Ajanta Pharma, FDC and Dr Reddy’s among others. While the pandemic has been harsh on many industries, the pharma sector by and large has been less impacted. “There was an uptick in our business which is reflected in our order books. We do not provide our clientele just packaging service in the form of cartons, but it’s an entire packaging concept that entails packing, protection, and preservation. Our ethos has always been to invest in equipment which can ensure limiting our packaging variations, continuity of supply as well as use it to develop new products,” said Sinha.

Among other things, for Sinha Bobst’s backup and after-sales service, pipped other rivals. “It’s a great technology,” he said. “We were looking for major cost savings in terms of executing lock bottom of different formats which came very easy on the Expertfold. The cost-saving factor was a plus for us and after getting the machine – the majority of our jobs converted from manual to direct converting on Bobst.”

Sinha explained, “Before we used to Braille embossing on die-cutter which was time-consuming and took huge time for make ready. Now with the Accubraille we can produce Braille jobs inline with less than five minutes of job changeover, better consistency, and higher productivity with production speeds of up to 70,000 boxes/hr. With the Bobst Accubraille, we have released time on die-cutting for die-cut jobs, while our production capacity for Braille cartons has increased three-fold with Expertfold.”

As for the Bobst sales and services team, it was quite a good experience, said Sinha. “From the point of sale to installation of the machine to after-sales services, it’s been nothing short of impressive.”

See All

See All