Labelexpo Europe 2025 Preview: Polyart to Spande

From digital and hybrid presses to advances in pre-press, curing and finishing, Labelexpo Europe 2025 in Barcelona, 16-19 September is set to spotlight future pathways for label converters

15 Sep 2025 | By Noel D'Cunha

Polyart

Hall-Stand: 3G50

The France-based company builds its label and packaging story on five pillars: sustainability, digital printing, security, packaging and services. At the core is its recycled range, r-Polyart, r-Fluolux, r-Satinex and r-JetPrint Aquaskin, developed with post-consumer and post-industrial content. Polyart says these grades support circular economy goals while meeting recyclability, biodegradability and food contact standards. On print technologies, the company promotes substrates compatible with dry toner, water-based and UV inkjet, and HP Indigo, designed to deliver durability and eco-responsibility in equal measure. Security comes into play with tamper-evident materials such as Polyart TE, while LDPE and HDPE packaging films are claimed to bring sustainable advantages to flexible formats. Polyservices rounds out the five-pillar vision with toll coating, extrusion, gravure printing and lamination, offered as collaborative services for converters. Polyart positions this as a way to co-create customised substrates, keeping pace with fast-moving market requirements

Pluriservice

Hall-Stand: 3G30

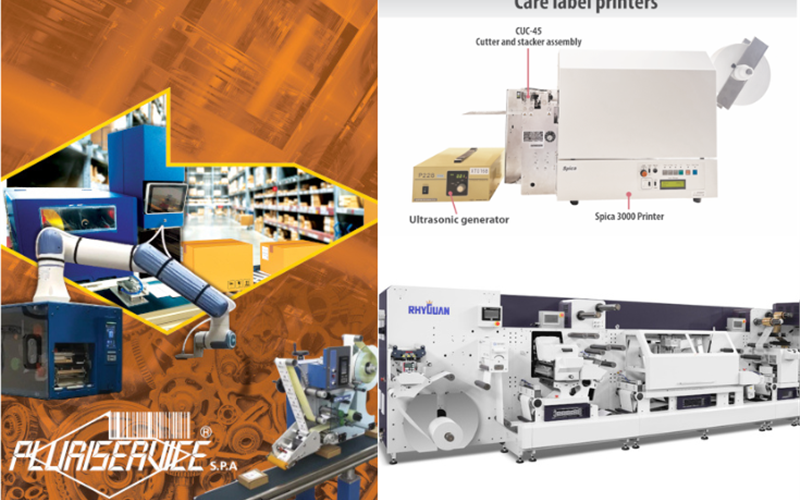

The Italy-based group will present a portfolio that blends labelling, robotics and software into complete automation solutions. The Apix Cobot Print Apply system will be a highlight, handling label retrieval and application across varied layouts and production lines with a modular design that simplifies maintenance. Alongside, Apix automatic labelling systems will demonstrate fast and precise application across product types, aimed at lifting both productivity and packaging quality. On the software side, the company will show tools for real-time production monitoring, warehouse management, data collection and print automation. Visitors can expect a joined-up approach to labelling and factory automation.

Polyonics

Hall-Stand: 5G85

The US-based manufacturer will unveil a new line of high-performance label materials aimed at electronics, automotive and aerospace applications. Built on coated polyimide, the labels are UL-certified, REACH and RoHS compliant, and flame-retardant. Advanced coatings will protect barcodes from abrasion, flux and aggressive cleaners, keeping them readable after exposure to heat and chemicals. Backed by pressure-sensitive adhesives formulated to hold through solder reflow and harsh wash cycles, the labels are designed to stay put where ordinary materials fail. With more than 30 years of R&D, Polyonics will present American-made solutions that combine compliance, durability and reliability in extreme conditions.

Printmark group

Hall-Stand: 3E14

Partnering with Japanese manufacturer Chuwa Co, Printmark Group will present the Spica Series textile printers for nylon and satin labels. The lineup includes care label printers for woven tapes and single-tag printers for sheet tags, aimed at efficient and flexible production. A highlight is the Spica 3000, which enables double-sided printing with up to three colours in one pass. Optional integration with the CUC 45 ultrasonic cutter ensures clean, sealed edges without fraying, enhancing label durability.

Ravenwood

Hall-Stand: 5A52

Ravenwood is teaming up with Henkel to spotlight a fully integrated linerless ecosystem. The partnership centres on exclusive Henkel hotmelt adhesives formulated for Ravenwood’s Com500 coaters and Nobac applicators, designed to run cleanly, support high speeds, and perform reliably even in cold chain environments. Together, the two companies are presenting the Circle of Linerless, which links approved adhesives, silicones, base paper, application machinery, design services, and end-of-line vision and X-ray systems into a seamless, sustainable workflow. Ravenwood says its linerless labels are 100% kerbside recyclable, with APCO accreditation under the Australasian Recycling Label programme. Testing conducted with BioPRIA and Monash University showed pulp yields above 93.75%, underlining their recyclability credentials. With all machinery made in the UK and 90% of Nobac parts sourced within a four-mile radius of its Norwich base, Ravenwood estimates its solution prevented 7,000-tonnes of CO2 emissions in 2024.

Rhyguan

Hall-Stand: 5D43

The China-based manufacturer will showcase a complete finishing line with six machines. Highlights include the SMART inspection system, paired with the Won automatic slitting rewinder to demonstrate both manual and automatic blade adjustment. Two classic models, the Top Plua flexo and die-cutting unit, and the compact Top die-cutter, return in upgraded high-speed versions. For wine labels, the Plus330 will feature a new silkscreen unit, silkfoil and heavy-duty hotfoil module. Rhyguan also introduces a multi-head semi rotary flexo press.

RK Printcoat instruments

Hall-Stand: L25

The UK-based pre-press colour communication specialist will highlight the FlexiProof 100, a machine that replicates flexographic press conditions for realistic printability testing. Incorporating a custom LED UV unit, the system replaces traditional mercury arc lamps and runs at speeds up to 100 m/min on a wide range of substrates. RK will also showcase the VCML Pilot coater for R&D and QC, alongside its GP100, K303S Multicoater, Esi Proof, Klox Complete and K Hand Coater lines.

Rotocon

Hall-Stand: 4D21

The South Africa-based supplier, in partnership with HS Machinery, will showcase three machines for label production and finishing. The spotlight is on the Chrome 450 flexo press, which the company claims delivers seamless operation, advanced embellishment and cost efficiency. Alongside it, the Ecoline RDF 340 will demonstrate digital label converting and finishing, while the Ecoline RSI 540 will run slitting, inspection and rewinding. Rotocon positions this line-up as a complete package for converters seeking modularity and performance on the press floor.

Rotometal

Hall-Stand: 3B99

The Poland-based specialist will highlight its composite sleeve technology and launch a new consumables division. With in-house R&D, Rotometal says it can tailor composite formulas to meet durability and performance requirements in narrow and mid-web converting. The consumables line, starting with UV inks and coatings, expands the company’s scope from tooling to integrated solutions. CEO Grzegorz Dołbniak notes the aim is to move beyond being a supplier to acting as a strategic partner for printers.

Roxi (CAB)

Hall-Stand: 3B93

The Germany-based company says its new Roxi label dispenser is designed to apply pre-printed adhesive labels at belt speeds up to 30 metres per minute. According to the company, Roxi ensures precise application on both flat and curved surfaces. It adds that the dispenser joins a wider range of cab systems, from desktop devices to modular units for automated plants. The company claims its focus remains on legibility, reliability and performance at the point of use.

Rudholm group

Hall-Stand: 7C53

The Sweden-based supplier will showcase its range of garment branding solutions spanning labels, trims and packaging. Its portfolio includes woven and printed labels, hang tags, heat transfers and badges, supported by globally recognised certifications. Packaging extends from e-commerce mailers to footwear boxes, while trim options include zippers, buttons and tapes. Rudholm also highlights its digital tools such as ShareLabel and Variable Data Cloud, integrating RFID and NFC. With 22 global sites, the company claims to deliver consistent, responsible solutions worldwide.

Spande

Hall-Stand:3E107

Provin Technos, the Indian partner of Shanghai Spande, will join the manufacturer at Labelexpo Europe 2025 where Spande occupies one of the largest footprints of the show. Across almost 1,000 sqm, the company is constructing a showcase of three flagship flexo presses that demonstrate both scale and engineering finesse. The S7 flexo press (fifth generation) stands as the centrepiece, an eight-colour, 450mm line fitted with dual die-cutting, LED-UV, hot air drying and one-touch changeover. Alongside it, the S5 Hybrid Press blends flexo and LED-UV inkjet with lamination, cold foil and a suite of finishing, a structure designed for versatility. Completing the set is the AC Series mid-wide web line, running at 250-m/min and spanning substrates from film to board, with in-line converting from roll to finished pack. For India, the first S7 will be installed at Citrus Packaging, Hyderabad, marking a landmark new foundation for local converters.

See All

See All