Cosmo launches Microenz BS for textile

Cosmo Speciality Chemicals, a wholly Indian subsidiary of Cosmo Films, has announced the development of Microenz BS sourced through enzymatic process, making it an environment-friendly alkaline pectatelyase. Thus, it helps eliminate the challenges posed by the chemical when sourced through traditional processes, such as high ETP load, usage of very harsh chemicals, wastage of water and time, etc.

02 Jun 2021 | By Rahul Kumar

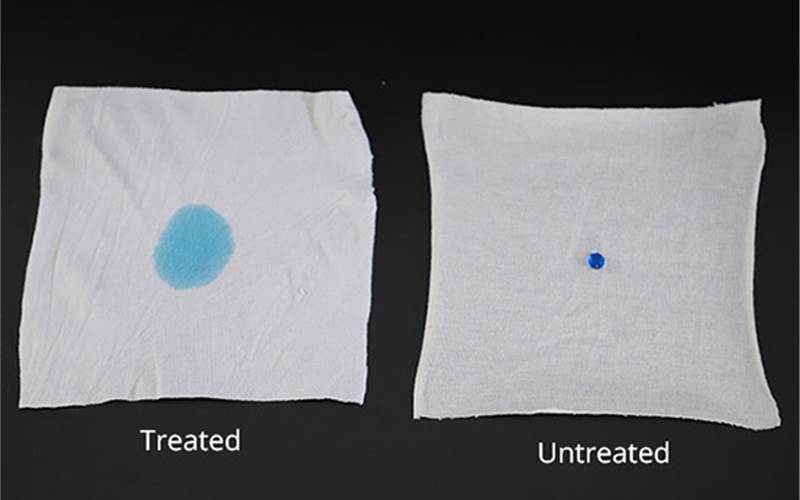

Embarked on the key product innovation principles of multi-functionality (performance oriented), process optimisation (energy, water and time saving) and sustainability (eco-friendliness), the advancement of Microenz BS ensures less fabric and garment damage as pectatelyase degrades the pectin from the primary cell wall of cotton without degrading the cotton itself, improved functional finish, lower yarn coefficient of friction, increased yarn elongation for improved weaving efficiencies, improved emerising and brushing properties, no degradation of cellulose and lower weight loss while being safe and easy to use as well as eco-friendly.

The chemical Microenz BS works in a way which is specially designed for the end users using alkaline pectatelyase as pectatelyase degrades the pectin from the primary cell wall of cotton without degrading the cotton itself. Microenz BS can also be used successfully for combined de-sizing and bio-sourcing (CDB). The dosage used for application is exhaust with doses 1.0% to 1.2%.

Anil Gaikwad, business head, Cosmo Speciality Chemicals, said, “For medium and darker shades on cotton yarn and knitwear, we suggest a one-bath-two-step pretreatment process. We propose an enzymatic pectinase treatment with Microenz BS 1.0 to 1.2% in combination with a mild peroxide bleach. This process includes a pectinase treatment as well as a mild peroxide bleach. The mild conditions lead to a softer handle in comparison to alkali-treated goods. Furthermore, bio-scoured cotton shows relatively good hydrophilic properties.”

See All

See All