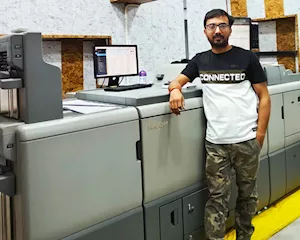

Rahil Dhami: Work can get monotonous at times, hence re-energise

In the Rapid Fire questions series, PrintWeek asks Rahil Dhami questions about print and beyond

21 Jun 2021 | By Charmiane Alexander & PrintWeek Team

What is the trait you most deplore in our industry?

Printers tend to save print/packaging costs which eventually leads to a lower research and development. It affects the evolution of the industry as a whole and the development for new innovations.

What is the quality you seek when you hire?

A strong sense of ownership. It promotes accountability and innovation. The mindset shift from the company’s work to my work is important. Qualities like handling cost effectiveness, material handling and machine maintenance is also essential.

As a print company, how do you keep up with industry trends?

I follow label associations like LMAI and IFCA. I check their websites regularly for information on developments, new machineries, printing techniques etc.,

Describe your day in two sentences

My work at the office mainly involves monitoring work processes, identifying bottlenecks, communicating action plans and setting up SOPs. Work can get monotonous at times, and hence networking and re-energising becomes necessary. I like going out for long drives after office hours.

What is the greatest strength of your firm?

We offer the shortest lead times for repeat order labels and blank labels in the industry at an economical rate. The reason behind it is because we manufacture in high volumes.

One print job you wish you had done?

Print liquor labels like Old Monk because of its design, value and volume.

Your thoughts on the future of packaging?

I see the future of packaging to be optimum, compact and minimalist giving highest priority to minimal or zero wastages.

Packaging innovations that could be the new normal?

The use of smart labels (RFID/NFC/QR codes) or IoT enabled tags to communicate the product details like nutritional value, manufacturing details and live time status of the shipment for shipping labels. Apart from that, recyclable labels and adhesives like RCA (recycling compatible adhesives) could be the new normal.

What do you most value in your customers?

My customers understand the importance, usage and functionality of label application in the supply chain.

What is your most ‘wow’ moment?

I was extremely happy when we successfully customised a rotary die-cutting machine to suit our high production needs for a few specific jobs. It helped us achieve 35% higher production at an economical rate.

What is your favourite Make in India print brand?

UFlex, due to its constant innovation on providing better solutions and adopting newer technologies for manufacturing.

If you could change one thing about your firm, what would it be?

I would like to improve the automation and material handling processes. Minimising the down-time and providing a convenient handling for the heavy weight items is vital.

See All

See All