Nordson’s solution to eliminate single-use plastics for collating applications in packaging

Abhilasha Singh writes about the company’s patent-pending solution that could eliminate single-use plastics used in shrink wrapping applications.

04 May 2022 | By Abhilasha Singh

Over the last many years, single-use plastics have found themselves being used by packaging designers to perform the product collation function, among other things. Today, industries continue to employ single-use plastics as stretch wrap and shrink film to collate multiple units of product in their packaging

lines.

In some cases, the collated bundle is separated into individual packs at the retail outlet. Here, the retail outlet disposes off the waste shrink film. In other cases, the plastic wrap is taken off by the end user, as in the case of beverage cans. Though convenient, this model is unsustainable. According to one report, India is the third largest producer of single-use plastic and is responsible for generating around 56,000 tonnes of single-use plastic waste every year.

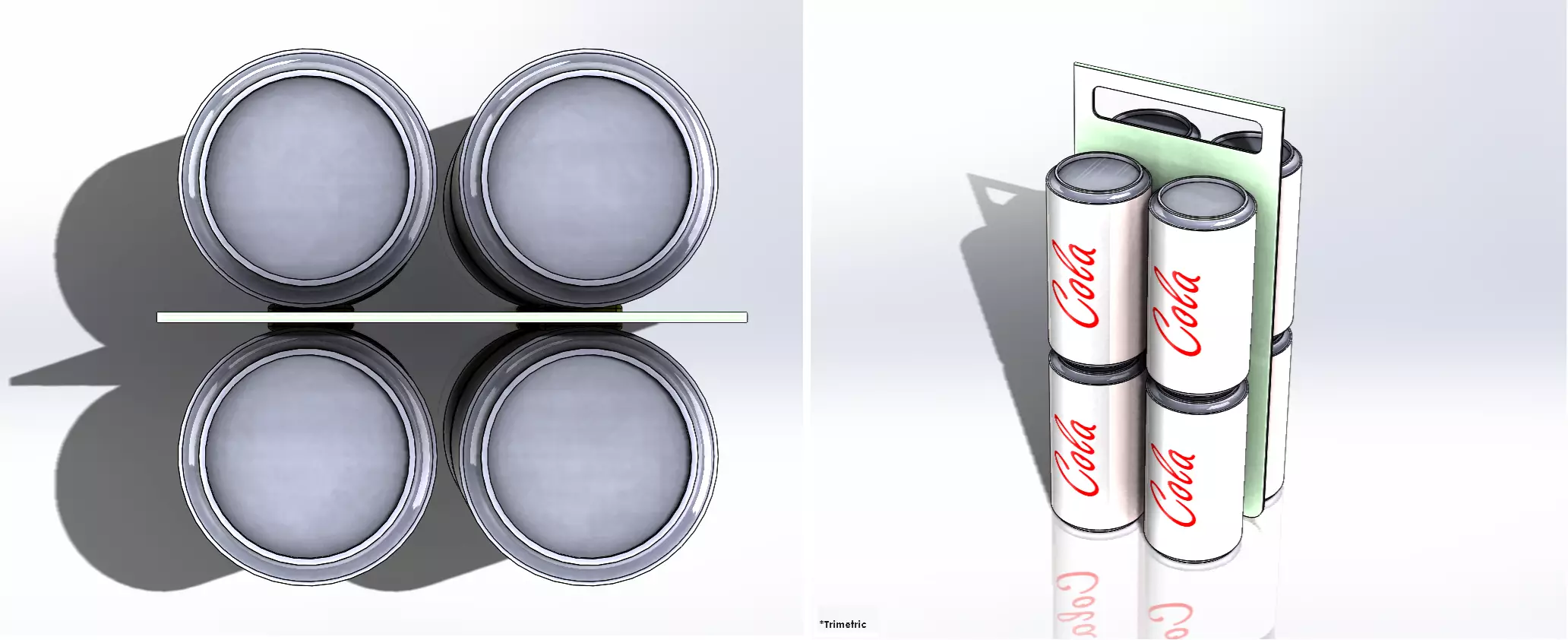

With global opinion and legislation turning up the heat against the usage of single-use plastics, Nordson India offers a patent-pending solution enabling manufacturers to do away with single-use plastics in shrink wrapped collating applications. To implement this process, all that is required is a carrier made of paperboard, textile, or a composite, along with a suitable pressure sensitive or fugitive adhesive. Part of the technology is in the selection of these materials, as not all work to produce desirable results.

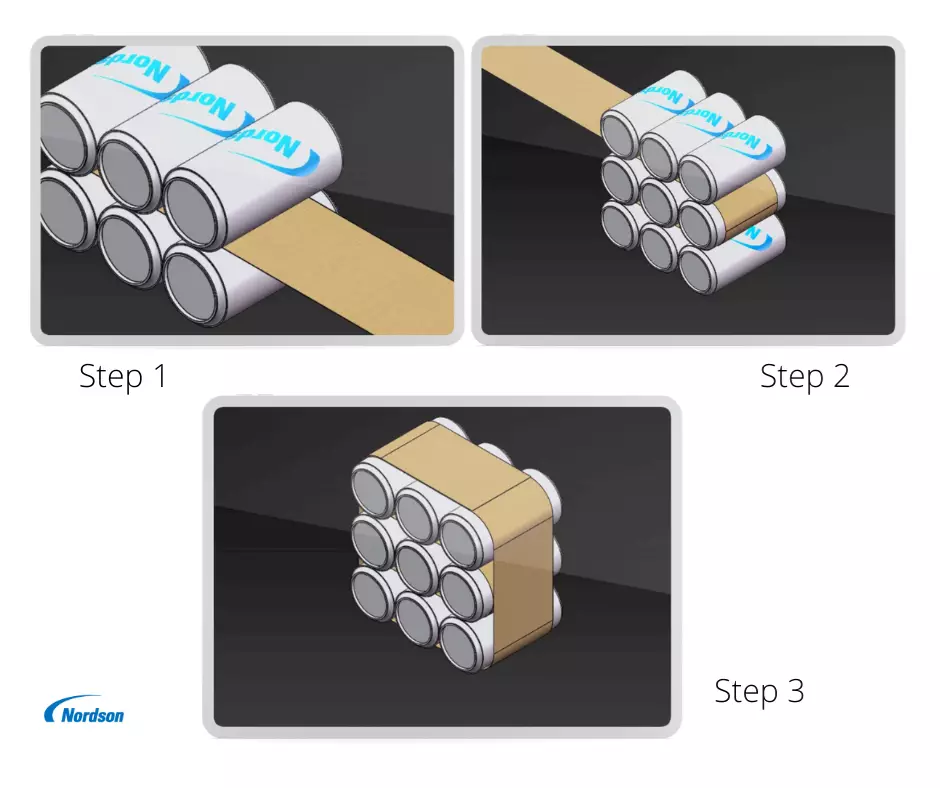

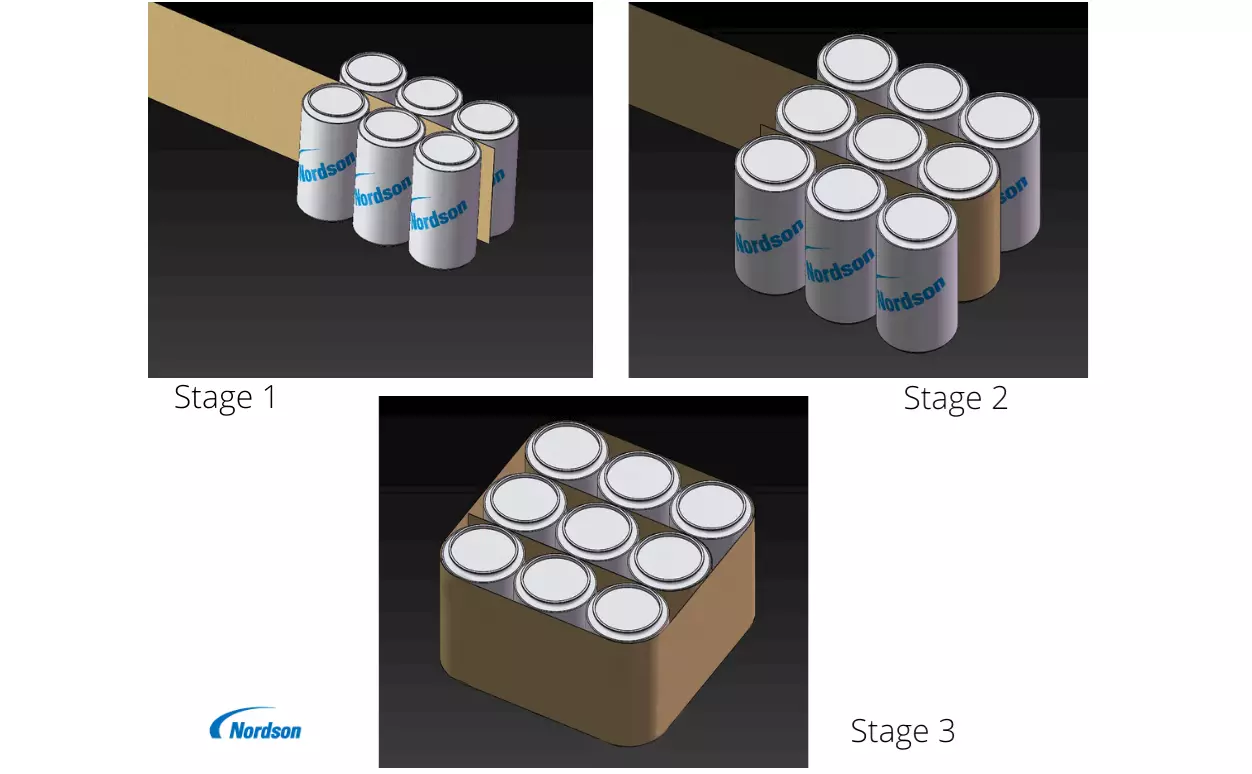

Adhesive beads are applied to both sides of the carrier in an automatic machine

To begin with, adhesive beads are applied to both sides of the carrier in an automatic machine. The product is then placed onto the adhesive and assembled into a collated bundle. The patent defines numerous shapes and sizes of the carrier, the kinds of products that could be collated and numerous

arrangements within the bundle.

There are numerous applications (all very promising), from the collation of books to the collation of personal care products.

The technology can be used for collation of books, personal care products and more

A similar technology also finds use in pallet stabilisation, where pallets are currently stacked and wrapped with stretch film. Yet another application is in tray packing, where small packs of beverages are placed on a tray and then wrapped with shrink film.

A question that is often asked is why products cannot simply be stuck to each to form a bundle. Extensive trials of this concept have shown that sticking products to each other is not practical. If the products stuck to each other are made of paperboard (for instance a carton of toothpaste), this process causes fibre tear in the carton when the products are separated from the bundle.

If the products are made of metal (for example, cans of beverage) or plastic (for example, bottles of shampoo) residual adhesive on the product after its separation from the bundle, would make it unsaleable.

Nordson’s technology is being brought to the Indian industry through OEM machine manufacturers. It is a transformative technology that will enable packaging designers and brand managers to make big strides in meeting their sustainability goals.

The benefits

- Elimination of single-use plastic in collation applications.

- Compliance with government regulations.

- Cost reduction due to the elimination of expensive single-use plastic

- Significant reduction in energy consumption.

- Enhanced convenience.

- Flexibility in the design of the collated bundle.

- Flexibility in the product shapes that can be collated.

See All

See All