Me & My: Screen Truepress Jet L350UV

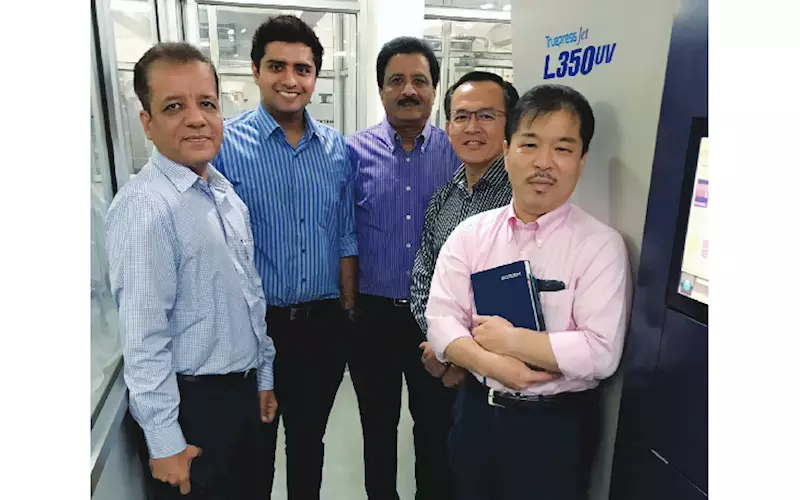

The father-son duo, Manish and Aarjav Hansoti of S Kumar Multi Products, share their experience of using India’s first Screen Truepress Jet L350UV

16 Oct 2020 | By PrintWeek Team

Tell us about your company.

S Kumar has been in the print business since 1984. It started with computer stationery, and in 1995, diversified to labels, and other print segments. Our major clients include companies in the lubricants manufacturing industry, edible oil industry and food industry. We specialise in large volume flexo jobs and medium-run roll-to-roll offset jobs.

Why Screen Truepress Jet L350UV?

Looking at the market condition and its demands, we experienced that the trend is short to medium-run jobs. Buyers wanted something new and exclusive, such as paddle-free or variable data printing jobs. This was the main reason for installing the Screen press.

What are the key benefits of the machine?

The machine provides a special raised effect printing, which is similar to the effect achieved in screen printing. I believe this is the USP of the machine. In addition, it enables us to intricately print even the smallest of dots. The print quality we achieve through the press in a single pass is excellent.

Any economical advantage the press offers?

One major advantage is that there are no click charges involved compared to other press manufacturers. In addition, we don’t have to pre-coat all the materials and the most obvious savings of flexo charges.

What difference in quality have you experienced?

As far as the same substrate is used, the clarity and consistency is maintained from the first supply to even the tenth supply. We are also able to match 80-85% of the Pantone shades accurately so as to give the client consistent print always. The printing is also more vibrant.

How easy is it to operate?

The machine is quite easy to operate. The interface is simple and the auto inkjet head cleaning system makes it easy for the operators to maintain. Plus, there are hardly any errors while running.

Do you see the press boosting your clientele?

Yes. Credit to the press, we have established a new offering for our existing clients. Earlier, for short quantities, our clients had to get labels printed on offset and paste them manually. With digital, they have the option to procure even 2,000 labels in roll form and get consistency in application and batch coding that they really appreciate.

We are also targeting new clients from all over India with our label-on-demand service that is very helpful for small companies and start-ups. We have worked hard to penetrate the marketplace and after 18 months, we are getting good numbers of small jobs.

Long runs are getting shorter, but are they so short that you have to rely on digital?

Yes, it is considerably short. And this has become a new market trend. Clients are coming up with way more SKUs than earlier. So for printing a job with 10 SKUs with the same size and a quantity of 4,000-5,000 each is much easier and quicker to print on digital than on flexo or offset.

Is the ink cost of the press viable?

The ink cost is very high as compared to flexo or offset. For instance, if the flexo cost is around Rs 1,500, for UV inks it is close to Rs 8,000-9,000 per kg for such digital presses. But digital is not a replacement of flexo, it complements flexo. When quantities are lower, flexo is not viable and then digital helps you in saving time and money irrespective of the ink cost. Installations of more digital presses might help in reducing ink cost in the future and we can start printing longer runs. We expect reduction in ink cost, which would be viabile for medium-run jobs.

What about job changeover?

While using flexo, our job changeover time was 30 minutes. In today’s date and time, one cannot afford to lose that kind of time when you have to run 30-odd jobs of smaller quantities. With Truepress, the time is much less.

How quick is the press?

We produced close to 25 jobs in a span of two days, which was only possible due to the Truepress Jet L350UV. We now have the capability to produce different SKUs in 24 hours. More than the speed of the press, you require a very strong, efficient and quick pre-press team.

Conclusion:

User’s verdict

- Speed ★ ★ ★ ★ ★

- Quality ★ ★ ★ ★ ★

- Reliability ★ ★ ★ ★ ★

- Value for money ★ ★ ★ ★ ★

Supplier’s response

Ajay Aggarwal, MD and CEO of Insight Print Communications, which represents Screen in India, says, “I believe every label converter will need to go digital sooner. Already, we have seen in the US and Europe that more digital presses are being bought by customers instead of conventional presses. Moving forward, we expect more and more short runs. The Truepress Jet L350UV press with media versatility does not need a primer coating for about 85% of label jobs. A corona unit is an option. The ink light fastness levels rates at seven for all the colours on the Bluewool scale. It can print on filmic substrates, as well as Tyvek, paper, flexible packaging, lamitubes and paperboard. Thus, it can be a machine for multiple applications.”

Contact details:

Sunil Thakeria

Insight Print Communications

www.insightwithin.com

Email: sunil@insightwithin.com

Mobile: + 91 98200 25665; Tel: + 91 22 48953417

See All

See All