Me & My... DuPont Cyrel Easy plates

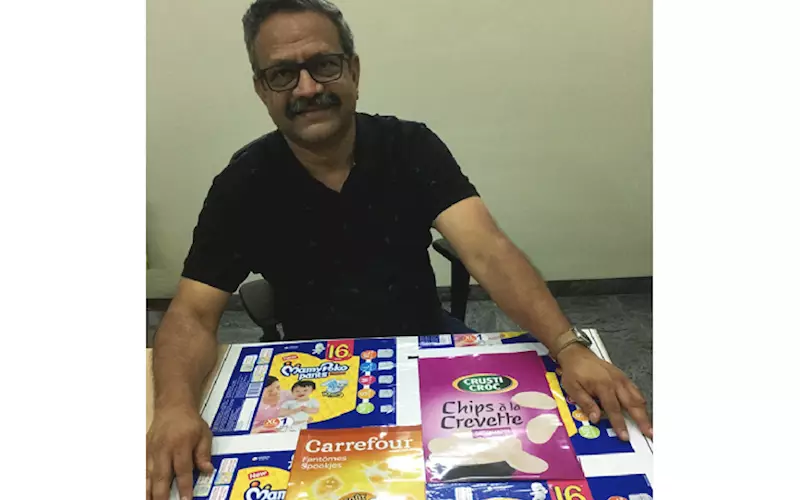

Vinay Nalawade, director-packaging business, Parakh Agro Industries, explains why Cyrel Easy plates are best for high resolution and critical jobs

13 Aug 2018 | By PrintWeek India

Please describe your company.

Parakh Agro, a part of Parakh Group, based in Pune, is the first mid-size Fortune 500 FMCG company in India (2017). The packaging business has a print capacity of 12,000 tonnes per annum with four CI wide web flexo print machines, three film extrusion lines, and two lamination lines, besides pouch making and slitting machines. We have specialisation in adaptive packaging that’s high on quality, low on cost and limitless in possibilities. The key to managing this ambitious portfolio is based on three simple principles — expertise, partnership and trust.

When did you start using DuPont Cyrel Easy plates?

We started using Cyrel Easy plates in 2016 for jobs which were critical to quality and had long print run.

What are the properties of the products you like?Definitely higher ink transfer and higher resolution. Very less ink fill up which reduced press stoppages. Cyrel Easy plate material enables less dot gain which is a good feature for quality, halftone long print run length jobs.

Why did you decide to use the product?

Most of the jobs we do are high resolution and critical to quality for PHC and exports segments. Better lay and less press stoppages were our needs. Cyrel Easy was the best fit after the initial trials and with our repro house, Veepee Graphics, and DuPont India team’s support, we could master it over time. Backing tape selection is also an important factor which should not be overlooked. The plates deliver high ink transfer, colour saturation and higher consistency, long runs resulting in improved press efficiency. The new Cyrel Easy technology platform simplifies the pre-press process by building the flat top digital dot directly into the plate, resulting in increased productivity and consistency.

Is there anything that you do not like or can be improved?

Vignette ending can be improved, may be with a combination of pre-press software modifications and plate processing qualities.

What’s the quality like?

The quality we are producing from the Cyrel Easy is comparable or even better than a rotogravure print. It has improved colour saturation and high ink transfer. Halftones are much better.

How easy is it to use?

We did not face much issue to use these plates on a regular basis for most of our jobs. We did most of the designs on DuPont plates and converted all to Cyrel Easy plates.

Would you say that it offers value for money? Please explain how?

Yes, I feel it offers value for money. If you look from an overall performance index and cost saving consumable, it makes sense to use Cyrel Easy plates. Definitely, job start up scrap and during job run scrap goes down by significant amount. Moreover, it’s a fit for a convertor who is quality conscious. In this highly cost competitive packaging market, internal operational efficiency plays a key role in profitability. Less machine stoppages is one very important point. Cyrel Easy plates definitely play an important role to support the convertor to increase profitability.

Were there any difficulties experienced during the consumption or while operating on the machine?

Initially, while using the plates in cyan colour, we faced high dot gains, which was difficult to run continuously on press. With the expertise of our repro house, Veepee Graphics, and the support of DuPont’s global team, it was resolved soon. The repro house also had to modify a few settings to cope with Cyrel Easy plates on a consistent basis. Even few changes were made in ink chemistry to cope with this issue successfully.

See All

See All