Industry report: How technology is fueling a revolution — The Noel D'Cunha Sunday Column

Across books, labels and packaging, the Indian print industry is no longer responding to trends defined elsewhere. Instead, it is reshaping what trends mean by allowing printing technologies to leapfrog applications, compress timelines, and dissolve old boundaries between scale, craft and creativity. PrintWeek's Book of Trends captures this shift not as a forecast, but as evidence, as PrintWeek team finds out

18 Jan 2026 | By Noel D'Cunha

India's printing and packaging sector is undergoing a profound structural shift, according to PrintWeek's The Book of Trends. The industry is no longer adopting global technology trends, passively. Instead, a new 'application-first' model is taking hold, where market demand for books, labels, and packaging is driving technological adoption and innovation. This is allowing Indian players to compress timelines, dissolve traditional boundaries between scale and craft, and redefine what success looks like.

Printers and converters are no longer asking what a machine can do. They are asking what an application demands, and then bending technology, workflows and materials to serve that demand. The result is not incremental progress, but leapfrogging. Capabilities once confined to niche or premium segments are now appearing at unexpected scales and in unfamiliar places.

This is not a story of one technology winning over another. It is a story of boundaries blurring, and of scale, speed and sophistication being redefined.

Books: mastering controlled complexity

Books offer the clearest illustration of this shift. At one end, education publishing continues to demand massive print runs, unforgiving deadlines and absolute reliability. At the other, speciality, trade and print-on-demand titles are stretching finishing, personalisation and material intelligence.

What stands out is how these worlds now overlap. Education books with print runs exceeding 100,000 copies carry design intelligence once considered indulgent. Two-colour strategies pairing black with a Pantone shade guide comprehension, while 50- and 60-gsm papers used for UPSC and NCERT titles deliver opacity without weight.

Complexity has migrated into the factory. Large-run textbooks now integrate section sewing, rounded spines, ribbon markers and hard-case binding within single workflows, demanding orchestration across press and post-press rather than brute-force production.

At the other end, digital printing has redrawn the idea of a short run. The Book of Trends documents everything from single-copy jobs to runs of 3,000–3,500 copies on digital web presses for coaching-class publishers. One standout title featured nearly 50 types of personalisation within a single book, requiring exceptional control over data, pagination and paper engineering.

Speciality and trade books push this further. Multi-volume encyclopaedias printed digitally combine four-colour covers, slipcases, foiling and PUR binding. Sprayed and multi-colour book edges are no longer novelties, but deliberate design choices that turn the book block into an object of desire.

The picture that emerges is one of controlled complexity. Book printers are mastering multi-stage binding, diverse materials and exacting finishes. The leap here is organisational as much as technological. The modern book printer is a systems integrator.

Labels: tactility meets scale

If books demonstrate control, labels demonstrate ambition. Always technically demanding, labels have now embraced sensory design at industrial scale.

A honey label mimicking butterfly wings lifting off the bottle exemplifies this shift. Using flexo plates, thin fibres and controlled creasing, a static surface becomes kinetic. Elsewhere, a whisky label simulated leather grain on plain paper, convincing enough to help the brand expand into more than 70 international markets.

What defines the leap is scale. Intricate foiling, tactile varnishes and layered effects are now being produced across runs exceeding 1,50,000 labels, demanding repeatable finishing discipline as much as press capability.

Shrink sleeves add further complexity. One coffee liqueur brand integrated foiling and tactile effects onto sleeves engineered to distort perfectly around complex bottle shapes. In another case, copper foils and textured varnishes appeared on custom die-cut sleeves without loss of clarity after shrinkage.

Sustainability is no longer a constraint. A dairy brand’s one-million-label run on recyclable LDPE film delivers durability and food safety alongside sharp illustration. Labels have become storytelling surfaces, tactile experiences and sustainability statements in one.

Mono cartons: precision at pace

Mono cartons sit at the crossroads of print, packaging and logistics. They must protect, inform and attract, often simultaneously. The Book of Trends shows how technology enables this with speed and finesse.

Food and beverage cartons reveal substrates chosen as deliberately as inks. Dry fruit boxes use stiff virgin boards to support cavity structures, gold foiling and windows without warping. Tea cartons rely on coated boards that accept botanical artwork and metallic highlights without cracking at folds.

Material intelligence extends further. Boards resistant to oil migration keep artwork crisp on bakery cartons. Whisky cartons lean on high-bulk boards capable of holding deep embossing and metallic gradients without compromising glued edges.

Digital and hybrid workflows are central here. Short runs for launches and regional SKUs move quickly, while gravure and offset dominate long-run laminated structures. The leap lies in how seamlessly these workflows coexist.

Mono cartons have become precise instruments of brand communication, engineered for transport stress and shelf impact alike.

Rigid boxes: engineering experiences

Rigid boxes best capture packaging’s shift from function to narrative. Once defined by sturdiness, they are now vehicles for interaction and memory.

An influencer kit produced in just 100 units combined HP Indigo printing with EVA foam inserts cut on digital tables, proving luxury need not depend on scale. Another box used a rise-up mechanism to lift perfume bottles as the lid opened, turning unboxing into choreography.

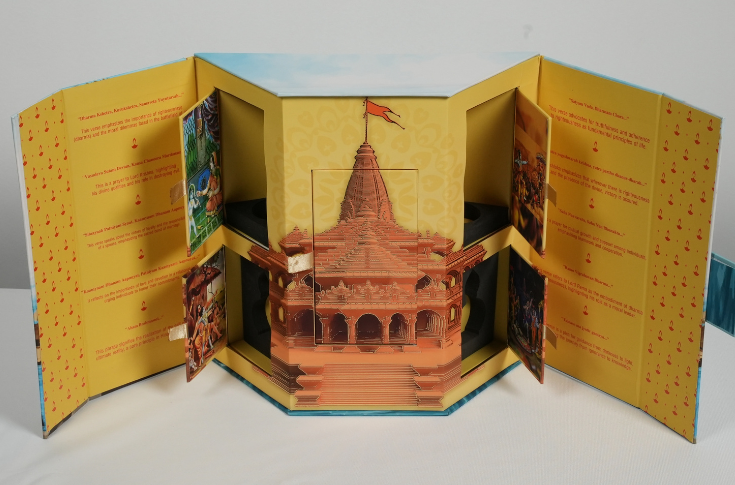

Festival gifting pushed this further. A Diwali dry fruit box balanced vegan leather handles with brass locks. A Ram Mandir-themed perfume set used pop-up engineering and devotional storytelling. A pyramid-shaped baby shower box solved functional challenges through modular, Lego-like design.

The most striking example was a Ganpati mandap box for a real estate brand, integrating CNC block filing, foiling, embossing, lighting and sound. Built from Kappa board yet styled to resemble carved wood, it was less packaging than installation.

Sustainability underpins these innovations. Magnet-free closures, recyclable structures and efficient board usage show luxury no longer depends on excess. Rigid boxes are no longer endpoints. They are experiences designed to be kept and remembered.

Presses become production platforms

Printing technologies are no longer operating in silos. Offset, digital, flexo and gravure are defined less by what they replace than by what they enable together. The modern print floor is organised around outcomes.

Digital presses such as HP Indigo, Gallus Labelfire and Canon now sit at the heart of workflows spanning rigid boxes, labels and research cartons. Output is routinely paired with digital cutting tables, EVA foam systems and advanced post-press lines, making the press a starting point rather than a destination.

In books, Canon digital presses underpin encyclopaedias, trade titles and short-run education books with covers, slipcases, foiling and embossing executed end-to-end. Jobs once split awkwardly between offset and specialists are now integrated.

Flexo has shed its single identity, combining screen units, cold foiling and inline UV to scale boutique finishes. Gravure continues to dominate flexible packaging, but increasingly interacts with digitally printed cartons, labels and promotions.

Post-press systems, from Scodix- and JetVarnish-type embellishment to advanced adhesive technologies using EVA, PO and PUR, act as quiet connectors across segments.

Presses are no longer endpoints. They are platforms within integrated production systems.

When trends are built on capability

Trends once announced themselves through surfaces and finishes. Today they run deeper.

Rigid boxes with rise-up mechanisms and magnet-free closures are not stylistic flourishes. They reflect mastery over board behaviour, cutting precision and adhesive performance. The trend is reliability at scale.

In labels, the signal is repeatable tactility. Leather-grain effects, butterfly-wing structures and sand-touch coatings are scaled across tens of thousands of metres without loss of registration.

Books offer another signal. Sprayed edges, multi-colour book blocks and fabric-textured covers show printers confident enough to treat the book as a designed object.

In mono cartons, trends are structural. Boards resistant to oil, humidity and stress enable windowing, embossing and metallic effects to coexist. Digital enables speed, offset and gravure deliver scale.

Across segments, trends are no longer about what looks new. They are about what can be executed consistently, repeatedly and at pace. That is why the trends in this Book feel durable. They are built on production intelligence, not fashion.

Postscript

The Book of Trends is the result of months of work by the PrintWeek editorial team, which sifted through more than 1,000 print and packaging samples submitted across categories for the PrintWeek Awards. Each sample was evaluated not just for visual appeal, but for how technology, material choice and execution came together to solve real-world challenges. The result is a curated record of how print is being reimagined across books, labels and packaging.

The Book of Trends can be downloaded free of cost. Click here.

See All

See All