How AGPC has been empowering its students with tech skills — The Noel D’Cunha Sunday Column

Arasan Ganesan Polytechnic College (AGPC) in Sivakasi has been conducting training programs. This includes a one-day Photoshop training program for print students and a two-day training program for diploma students. Dr M Nandakumar, ME, PhD and principal and HOD of Printing Technology at AGPC, shares the highlights.

22 Jun 2025 | By Noel D'Cunha

An eyewitness told PrintWeek that the two-day training program at AGPC was buzzing with energy. Mechanical, Electrical, and Electronics Engineering Diploma students, who had just secured placements abroad in leading printing organisations, were gathered in the main hall.

V Nambirajan, a distinguished printing course trainer from Chennai, led the training. Nambirajan covered topics such as types of corrugated flutes, offset printing process and offset printing machines, flexo and gravure printing processes, digital printing process, graphic design software, cost estimation techniques, importance of internships in printing presses, paper GSM measurement, and use of magnifying glass for print sample verification.

On day two, the training shifted towards the technical aspects of their new roles. Experts from the printing organisations conducted workshops focusing on the latest technologies and processes. Hands-on activities allowed the students to apply what they had learned, and the interactive sessions fostered collaboration and problem-solving. The nervous students began to find their confidence, realising they were well-prepared for the challenges ahead.

The training program concluded with a ceremony where each student received a certificate of participation. Dr Nandkumar says, "As they walked out of the hall, there was a palpable sense of optimism and readiness. They were no longer just students; they were about to embark on international careers, armed with new knowledge and collaboration with leading printing firms." In a way, the two-day training was more than just a program; it was a launchpad for their dreams.

Dr Nandakumar shares with PrintWeek, "We organise Placement Days, such as Placement Day 2023 and Placement Day 2025, and also celebrate Printers Day, as seen with Printers Day. AGPC also organises career guidance programs." He says, "The main focus is programs related to printing technology and career guidance, alongside training relevant to engineering fields within the context of printing organisations.

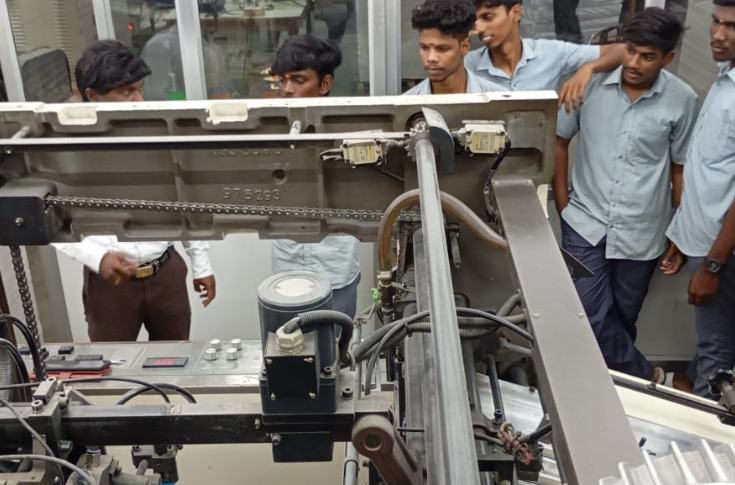

Empowering students at Balaji Fine Arts

The AGPC students gained practical experience at Balaji Fine Arts in Sivakasi. Dr Nandakumar says, "Balaji is a commercial print firm equipped with advanced machinery, including a four-colour CPC kit and a programmable cutting machine, which served as the venue for the hands-on training. The facility was made exclusively available to the AGPC diploma students for selected days, allowing for focused demonstrations of the working principles of various machines. Students were able to observe and learn the entire process, from the initial feeding of materials to the final delivery of printed products.

Dr Nandakumar says, "A key highlight of the program was the opportunity for students to interact with the experienced tech-crew at Balaji Fine Arts. The staff members were on hand to explain the intricacies of the machinery and answer the students' questions, providing valuable insights into real-world printing operations." This direct engagement with industry professionals enhanced the students' confidence as they prepare to enter the graphics art industry.

Dr Nandakumar says, "The training program at Balaji Fine Arts is a testament to AGPC's commitment to providing its students with practical, industry-relevant skills and preparing them for successful careers on an international stage. The experience gained will undoubtedly be a significant asset to the students as they embark on their new roles in India and overseas."

Packaging at AGPC: A focus on design and sustainability

Other than his students, Dr Nandakumar's focus is on packaging and innovation in packaging designs to attract and fulfil the needs of the day, targeting sustainable, friendly packaging. He says, "Knowledge is also provided by focusing on packaging technology on all types of packaging, including fibre-based (like carton boxes and corrugated products), flexible, metal, and glass, to prepare students for diverse industry needs."

At AGPC, the students are sensitised about waste reduction through green campus initiatives. One thing Nandakumar is proud of is "The collection of paper waste from all the branch students (720 students) and making handmade paper out of it."

Also, students are made aware of operational expenditure, especially the 34% share of substrate costs, and AGPC faculty integrates costing and management modules into the curriculum, emphasising waste reduction in labs, and providing industry exposure to real-world cost optimisation strategies.

For this purpose, other than Balaji, AGPC students have visited the factories of The Hindu in Madurai, Lovely Offset, and Bell Printers (both in Sivakasi). Nandakumar says, "Faculty members regularly visit the Sivakasi presses to update knowledge about print applications and to fulfil the factory needs for manpower supply." One mantra which AGPC swears by: "Innovation is the key to sustainability and market success."

See All

See All