Eco Flexible’s digital rethink — The Noel D'Cunha Sunday Column

In a discussion during Labelexpo Europe 2025 in Barcelona, Simon Buswell, UK-based Eco Flexibles sales and marketing director, reveals how the company has revolutionised short-run flexible packaging with Fujifilm’s Jet Press FP790, fusing digital precision and a bold commitment to sustainability

09 Nov 2025 | By Noel D'Cunha

In the fast-evolving world of packaging, agility has become the new measure of competitiveness. For Eco Flexibles, a company that began as a creative offshoot and evolved into a full-fledged producer, the answer lay in digital transformation. It was not just about installing a new press but reimagining how packaging could work for modern brands.

“Eco Flexibles was born out of a simple idea,” says Simon Buswell, sales and marketing director. “We wanted to make flexible packaging accessible to brands of every size, without long lead times or minimum order quantities.” The company’s origins in design gave it an early understanding of the disconnect between what brands wanted and what traditional converters could deliver. The team saw that small and medium-sized brands were innovating faster than the print technology serving them. That realisation set Eco Flexibles on a new path.

From agency roots to digital production

Eco Flexibles story started within a creative agency, crafting packaging for up-and-coming food, beverage, and health brands. Clients craved short runs, endless SKUs, and frequent design tweaks, but traditional flexo printing simply could not keep pace. High plate costs and slow setup made small batches impractical.

Buswell remembers the turning point. “We realised that digital was the only way forward. Our customers were not asking for cheaper print; they were asking for flexibility and speed.” That insight sparked Eco Flexible’s evolution into a standalone, digitally driven business. The goal was not to replace flexo, but to create a nimble, responsive model for today’s brands.

The choice of the Fujifilm Jet Press FP790

When Eco Flexibles evaluated digital solutions, it was looking for a platform that could bridge quality and compliance. “We needed a system that could deliver the image quality of offset and meet the performance standards of flexible packaging,” says Buswell. After extensive trials, the company chose the Fujifilm Jet Press FP790.

Eco Flexibles achieves BRCGS Packaging Grade AA certification

The FP790’s water-based inks were a defining factor. They offered the food-safe, low-odour, and regulatory compliance necessary for primary packaging applications. But just as importantly, they allowed Eco Flexibles to pursue its environmental goals. “Fujifilm’s water-based system aligned with our sustainability ethos,” Buswell explains. “It was not only about performance but about responsibility.”

The press brought something rare in digital: true scalability. The FP790 seamlessly handled everything from micro-runs to mid-sized jobs, all while maintaining flawless colour and productivity. For Eco Flexibles, this versatility transformed digital print from a niche tool into a production powerhouse.

Automation as a philosophy

Automation pulses at the core of Eco Flexibles operations. The team engineered a workflow where manual steps vanish, letting jobs flow effortlessly from client upload to proofing, approval, and production along a digital backbone.

“The FP790 integrates perfectly into our workflow,” says Buswell. “Artwork goes straight from the client to pre-press and then into production. The colour management is so stable that we can trust every metre to look identical.”

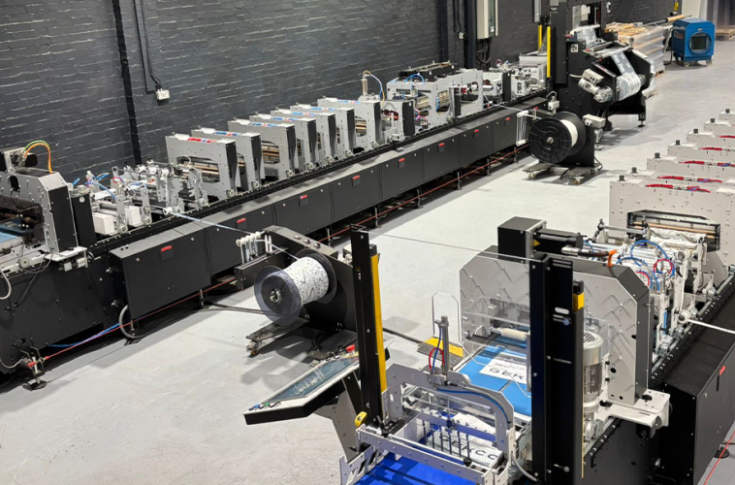

Eco Flexibles production ecosystem stretches far beyond the press. Laminating, slitting, and pouch-making are orchestrated by data-driven automation, guiding each order along a traceable path. This reduces errors, slashes lead times and lets operators focus on what matters most.

Eco Flexibles second Karlville Swiss KS-SUP-400-D pouch machine

Automation keeps Eco Flexibles nimble. “We can offer the responsiveness of a much larger organisation because our systems do the heavy lifting,” Buswell notes. “The key is not to see digital as a printing method but as a connected ecosystem.”

A new business model for flexible packaging

Eco Flexibles is rewriting the rules of packaging economics. Rather than selling print as a commodity, it offers flexibility as a service. Clients now plan campaigns, not just print runs. “Because there are no plates or setup costs, a client can order five or ten design variants for the same cost as one flexo job,” says Buswell. “That changes the conversation entirely.”

This agility is a game-changer for start-ups and niche brands racing to launch new products and stand out on the shelf. Established companies also benefit, running targeted promotions or seasonal editions without the burden of excess inventory or waste.

Digital print turns packaging from a passive container into a dynamic marketing tool. For Buswell, this marks a cultural sea change. “We are not just making packaging,” he says. “We are enabling brand stories to move at the speed of their ideas.”

Sustainability in practice

For Eco Flexibles, sustainability is not an added feature but the foundation of its operations. From material sourcing to ink systems, every decision is guided by environmental responsibility. “The ‘Eco’ in our name is not decorative,” Buswell says. “It reflects how we think about materials, energy use, and waste reduction.”

The FP790’s water-based inks champion recyclability and shrink environmental impact. Digital workflows curb overproduction, so customers print only what they need. Eco Flexibles also partners with substrate suppliers to trial recyclable and compostable films, often piloting new materials in real-world jobs.

“Digital print makes it easier to experiment,” Buswell explains. “You can test a new substrate or coating in a short run without the cost of retooling or new plates.” This agility helps accelerate the industry’s move toward sustainable packaging formats that meet performance and regulatory requirements.

Eco Flexible’s energy-smart facility and minimal waste output reinforce its green credentials. “Sustainability is a business advantage now,” says Buswell. “Brands expect it, consumers demand it, and the technology finally supports it.”

The quality question

One of the lingering doubts in the early days of digital print was quality. Could it match the precision of flexo or gravure? The FP790 has largely settled that question. Buswell notes that its colour consistency and detail rival conventional methods. “There is no compromise,” he says. “The FP790 gives us offset-like sharpness and depth with the durability that flexible packaging requires.”

Colour management plays a critical role. The press’s closed-loop calibration system ensures that repeat jobs look identical, even across different production cycles. “The first metre of a rerun looks the same as the first metre of the original job,” Buswell explains. “That reliability builds confidence for brand owners.”

Efficiency through intelligence

Data intelligence powers Eco Flexibles efficiency. Every production stage is seamlessly connected by software that schedules, tracks, and reports. Automation slashes human error, while data insights sharpen planning and forecasting.

“Automation is what allows digital to scale,” Buswell says. “Clients upload artwork, approve proofs online, and track progress through a portal. It is transparent, fast, and efficient.”

This transparency has built trust among clients who are accustomed to traditional print workflows. “They can see exactly where their job is and when it will be delivered,” Buswell adds. “It transforms how we communicate.” Automation is also rewriting the company’s economics. By cutting labour hours and set-up waste, Eco Flexible keeps overheads lean. This efficiency unlocks competitive pricing, even for the shortest runs.

Changing customer expectations

Digital transformation has reshaped customer behaviour. Clients once boxed in by order minimums now revel in creative freedom. “They love that they can launch ten variants instead of one,” says Buswell. “They can respond to trends instantly.”

Eco Flexibles is seeing a surge in personalised and region-specific packaging requests. With variable data, every SKU can feature unique artwork, messaging, or QR codes for traceability and engagement. For many brands, the boundary between marketing and production is fading.

“Packaging has become interactive,” Buswell observes. “It is no longer just a wrapper; it is part of the brand experience.”

Eco Flexibles approach fuels this shift, blending lightning-fast turnaround with premium quality. The result is packaging that keeps up with the speed and imagination of today’s market.

Rethinking the flexo-digital balance

Buswell believes that flexo and digital will continue to coexist, but their roles are evolving. Flexo remains efficient for long, standardised runs, but digital is fast becoming the preferred choice for everything else. “As digital speeds increase and costs continue to fall, the break-even point keeps moving upward,” he says.

He predicts that within a few years, digital could account for half of all flexible packaging production. “The market is heading that way naturally,” he notes. “Just as we have seen in labels and folding cartons, flexible packaging is now on the same trajectory.”

This change is powered by necessity, not novelty. Digital fits the demands of modern business, where brands must pivot quickly and avoid stockpiles. It is a fundamental shift, not a fleeting trend.

The business case for agility

Financially, Eco Flexibles digital-first model brings both savings and stability. On-demand production frees up capital otherwise locked in plates, materials, or idle stock. Pricing is based on value, not volume, giving clients transparency and peace of mind.

“Our clients understand that agility has value,” Buswell says. “They are not paying for ink on film; they are paying for flexibility, responsiveness, and confidence.”

This new way of valuing services deepens long-term partnerships. Clients now view Eco Flexibles as a collaborator in innovation, not just a supplier. “When you remove the friction between design and production, you create collaboration,” he adds. “That is where real progress happens.”

The future of digital packaging

Buswell envisions a future driven by material breakthroughs, automation, and data. Eco Flexibles plans to grow its digital capacity and expand its material range, introducing recyclable mono-material laminates and compostable options. The company also aims to weave intelligence into every package through digital print.

“Variable printing allows us to create unique identifiers for traceability and authentication,” he says. “It can support supply chain transparency or customer engagement. The potential is enormous.”

Eco Flexibles long-term goal is bold: make sustainable, short-run packaging the industry standard. “It is not just about what we can do today,” Buswell explains. “It is about building a platform that will make responsible production the norm rather than the exception.”

For Buswell, digital printing is about more than technology; it is about freedom. “It gives brands the freedom to move as fast as their ideas,” he says. “It frees us from plates, minimum orders, and waste.”

See All

See All