CDC Printers’ Ahmedabad blueprint

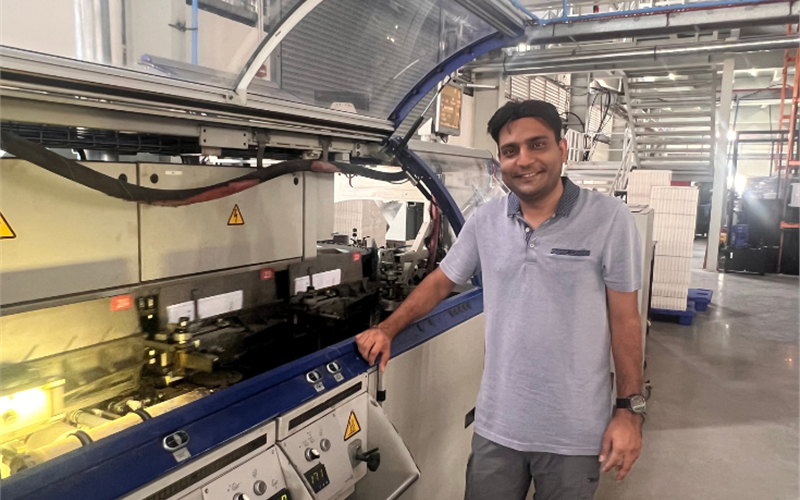

Manu Choudhury is busy retooling his book manufacturing facility in Ahmedabad through lean processes and digital transparency. Noel D’Cunha spends time at CDC’s newest facility

28 Oct 2025 | By Noel D'Cunha

Ahmedabad is not yet a household name in global book printing. But it might soon be. Kolkata-based CDC Printers, helmed by director Manu Choudhury, has launched a new plant in the city that blends sustainability, process intelligence and just-in-time transparency into one seamless operation. It is not flamboyant. There are no towering claims. But the factory represents something quietly radical: a vision of Indian print production built on process maturity, AI-enhanced systems and cultural clarity.

The story begins in West Bengal

For over a decade, CDC’s two plants in Kolkata served as test beds where hard lessons were learnt. Faulty book batches were returned, margins were squeezed, machines were pushed beyond their limits. “We did lots of errors in ten years,” Choudhury says. “We used Kolkata as our laboratory. All of that learning we’ve implemented here in Ahmedabad.”

Every mistake in Kolkata has found a preventive fix in Ahmedabad. For example, the chaotic multi-stage packing in Kolkata has been streamlined into an inline setup in Ahmedabad. Signature tracking, previously reliant on human checks, now uses a colour-coded logic system, drastically cutting errors. “In Kolkata, printing hota hai, binding hota hai, fir alag se packing hota hai (printing is done, binding is done, then packing is another process). That introduced errors,” Choudhury recalls. “In Ahmedabad, we’ve done it differently.”

The Ahmedabad layout itself is a reengineered version of everything CDC has learnt about the management of space. While the current book production facility uses 80,000-sqft, the plan includes a complex for packaging with dedicated zones for waste management and worker housing. “We’ve doubled the utility of the site with better planning, not just more real estate,” he notes.

Visibility as a value system

At the heart of CDC’s Ahmedabad facility is not just machinery but visibility. The live customer portal, currently in its demo phase, will soon offer end-to-end traceability to every buyer. “Sab kuch dikhega,” Choudhury jokes. (Everything will be visible.)

Clients can refresh their dashboards every five minutes to see how many books have been printed, how many cartons packed, and critically when their shipment will reach the destination port. Not when it left the factory. Not when it boarded a container. But the actual expected delivery at their door.

“To them, dispatch date is meaningless. What matters is when the container reaches them,” Choudhury explains. The ERP integrates with external APIs and shipping trackers to offer clients full transparency. Even internal quality checklists are logged live, with deviations flagged in real time. “You cannot go home and fill it in later. Live hona chahiye,” he says. (It has to be live.)

And this visibility is not just external. Internally, it serves as an accountability mechanism for quality teams. “If everything is on record, no one can fudge numbers. That alone raises quality,” he says. In fact, it creates a feedback loop: accurate reporting leads to accurate fixes. Even the barcode scanner on the packing line feeds directly into the portal, so clients see real-time progress.

For global clients who demand transparency, this is not just a feature. It is a filter. “When buyers in the UK ask if we have a customer portal,” Choudhury says, “We tell them: not just a portal. Something you haven’t seen before.”

A leaner, smarter engine

The big numbers behind CDC’s shift are not about speed alone; they are about people. In Kolkata, one-lakh books required 50 to 55 people working across three shifts. In Ahmedabad, the same volume is produced by 20 to 22. “Packing is inline,” Choudhury explains. “Which means errors that used to creep in, those have been eliminated.”

This drop in headcount is not about automation alone. It is about rethinking processes. Signature labels are now colour-coded. Material flow paths are minimised. “Koi bhi samajh jaaye, chhata signature pink colour chahiye, turant mil jaata hai,” he says with a grin. (Anyone can understand. If the sixth pink signature is needed, it appears instantly.)

Two Kolbus binding lines, and a Muller Martini perfect binding line, relatively new, European-standard installations, anchor the floor. Choudhury recounts a key decision: not just buying good machines, but investing in the way they are installed. “Engineers often benchmark Indian installs at speeds of 5,000 per hour,” he says. “We told them: 8,000 chahiye (we want 8,000). Just like in Europe.”

Soft-spoken culture, hard-edged tech

While the factory buzzes with automation, the people running it speak in measured tones. “If someone is not soft-spoken, fit nahi hoga (They will not fit),” Choudhury says. That softness, borrowed from CDC’s Kolkata roots, is now a cultural expectation.

It is not incidental. Choudhury believes softness signals something deeper: intent. “Ninety-nine per cent of people don’t have bad intent,” he says. “And if the intent is right, everything else is trainable.” He draws a line between capability and character. “If someone’s loud or brash, they might perform on metrics, but they won’t align with us long-term.”

Even now, those who are hired continue to train and shadow veterans from Kolkata. Some have been sent back for rotation. Others join refresher sessions at CDC’s tutorial centre set up in collaboration with Jadavpur University and RIPT. The message is simple. Be open, be respectful, everything else can be taught.

Designed for scale and dignity

Beyond the 80,000-sqft in operation, CDC’s Ahmedabad site is evolving into a blueprint for integrated manufacturing. The next phase, already under construction, will include a new packaging plant spread over 2.5-lakh-sqft. The structure, a ground-plus-two layout, has been planned not just for efficiency, but for dignity.

One wing of the building will house mono-carton and board conversion lines. The other will include an on-site waste management unit and residential accommodation for workers.

“This is not just packaging expansion,” Choudhury explains. “It’s an ecosystem upgrade.” The decision to integrate waste handling at the site came from years of fragmented experience. In Kolkata, waste was handled by third parties with inconsistent results. “Here, we wanted to own the loop,” he says. “If we claim to be sustainable, we must deal with what we discard.”

Even the spatial layout of the building has been drawn with process logic in mind. “Our biggest learning is that mistakes happen not on machines, but between machines,” he notes. So material movement, loading docks, rest areas and packing lines are all being designed to reduce crossings, misflows and downtime.

If CDC gets this right, the packaging complex will not just be an extension of the book facility, it will be a demonstration of what responsible, future-ready manufacturing can look like in India.

The profitability paradox

CDC’s profitability model runs counter to industry myth. Many assume that high throughput requires high headcount or cheap pricing. Choudhury disagrees.

He breaks it down: “I am not here to do cold foiling or niche embellishments,” he says. “I am a process guy. I will make you a Chinese-quality copy at a price no one else can.” The trick? Cost control through process design. “I can’t make the iPhone. But I can make a brilliant iPhone copy, and still make money.”

Critics often accuse the CDC of underpricing its services. Choudhury’s reply is simple: “Your profit calculation is wrong.” He believes most Indian printers are unknowingly making money, but cannot see it because their accounting systems fail to reflect this. “Their formula is outdated,” he says. “They think there’s no profit, but they just haven’t tracked it properly.”

In Ahmedabad, CDC’s formula is visible on screen. Job by job, shift by shift. That visibility combined with high throughput and low overheads is what makes the site work. As Choudhury puts it, “It’s not that we’re doing anything exotic. We’re just doing the basics right, bahut achhi tarah.” (very, very well.)

To read the complete feature, subscribe to our magazine and get your hands on the latest edition (October 2025) of PrintWeek magazine

See All

See All