Webtech's Flexomaster

Since its launch in January 2011, Webtech Engineering has installed 15 narrow-web Flexomasters, flexo printing presses in the world. 12 of these are installed in India. A report by Rahul Kumar

18 Feb 2014 | By Rahul Kumar

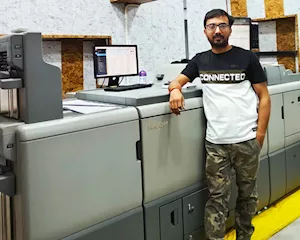

Webtech Engineering boasts of a strong line of clients from the label, packaging, security, stationery printing and converting segments. Kishore Kumar PS of Webtech Engineering, says, “Being a technology driven company, our target has always been to manufacture an affordable printing press for the label printers since overseas (European and American) presses are not affordable for a large section of our industry."

The narrow-web flexo printing press manufactured by the company is equipped with a full rotary flexo with semi-top loading system. “This product is flexible and suits different business needs. The flexible features ensure that the printers can cater to a wide range of industries. The printing press can achieve a top speed of 150 metres per minute,” says Kumar. The company estimates that productivity is generally about 25,000 metres per shift, depending on job changes. “The quick changing system ensures the machine is up and running in short time and the short web-length and quick register mechanism ensures minimised raw material wastage,” he adds.

The Faridabad-based company also manufactures converting machines and packaging machines, provides engineering services, fabrication equipment and equipment for solar energy. Kumar says, “We are often assumed to be a label printing press manufacturer but our portfolio extends to much more."

Established in 1998, Webtech had a team of experienced engineers to manufacture printing and converting machines. The company has a significant clientele-base spread over different parts of the country. Recently, the company has also ventured into exports. In last one year, it has exported machines to Nepal, UAE and Sudan, and is currently having discussions with clients in other countries.

In addition to its registered head office in Faridabad, the company also has a branch office in Chennai and zonal centres in Hyderabad, Pune and Kolkata. The company claims that it has the largest network of service engineers strategically located across the country for customer support. For its international clients, it has trained engineers located at Dubai, Kuala Lumpur and Manila.

Key customers

Some of the key customers of the company include Hitech Print Systems (Vijayawada), Stick Labels (Hyderabad), CM Printers (Delhi), Paper Script (UK), Master Simex (Bangladesh), and CSI (Oman).

| TECHNICAL SPECIFICATIONS |

| Maximum paper width 10” / 13.37'' (340mm) / 16” / 18” / 20” |

| Substrate 80-150gsm Label stock and paper |

| Sheeting repeat range 8”- 24” (203.2 610mm) |

| Maximum unwinder diameter 40'' |

| Maximum rewinder diameter 40” |

| Maximum mechanical speed 400fpm (120m/min) |

| Unwind tension control Electronic controlled magnetic particle brake |

| Unwind shaft Pneumatic |

| Web aligner Electro electronic |

| Infeed Independent driven motor synchronised with main drive |

| Printing Repeat 8'' - 24'' (for 16” width and above min size is 10”) |

| Plate cylinder Shafted top loading system |

| Ergonomics Tool-less with minimum changing parts and easy to operate waist height concept |

| Die cutting 3 stations for multiple use |

| Die Repeat Range 12''- 24'' (304.8 610mm) |

| Options Perforation, sheeting, hot foil etc. |

| Web inspection Digital camera with real time display |

| Maximum Rewinder Diameter 40” |

| Optional features Inkjet printing and gravure printing |

See All

See All