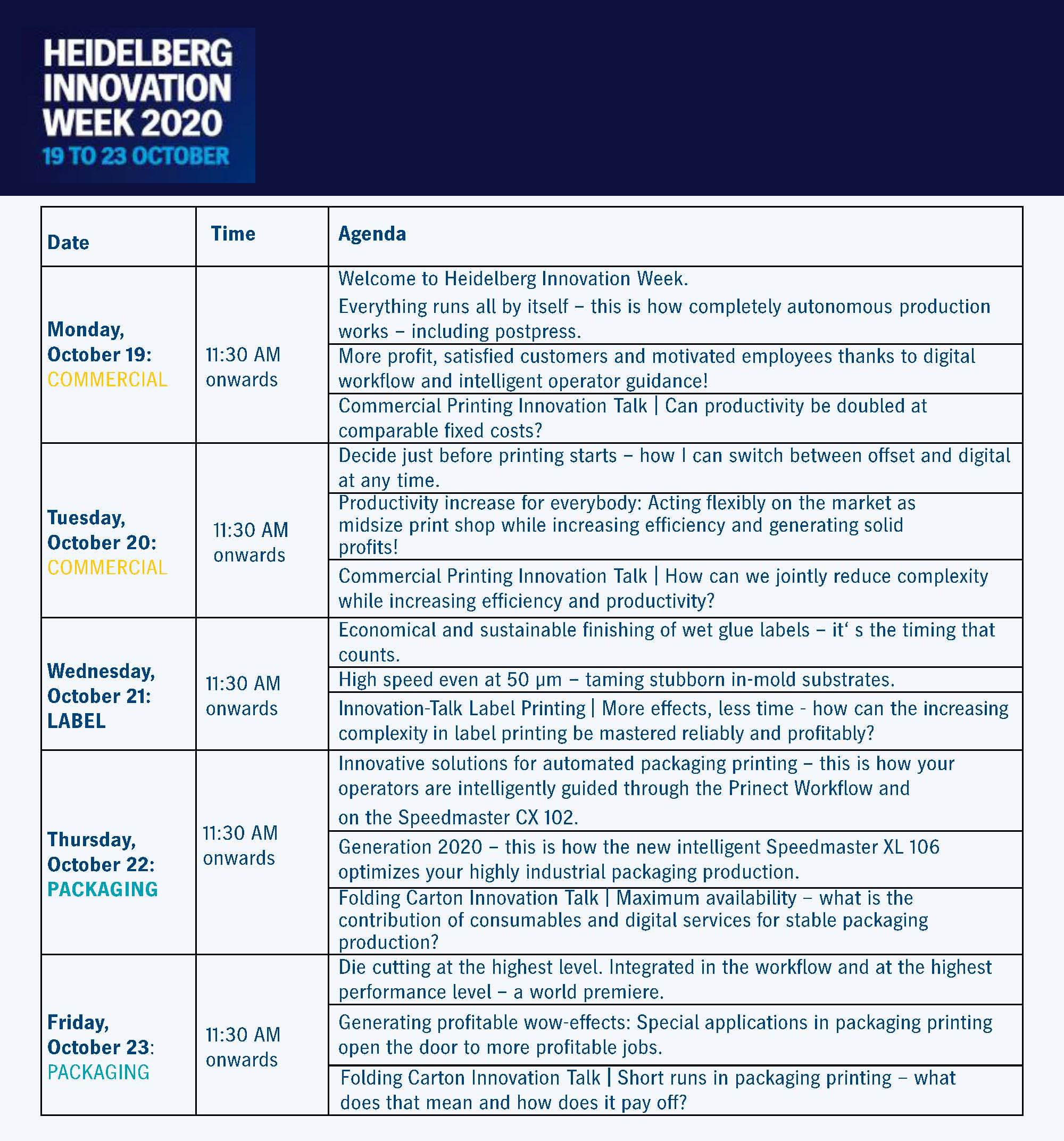

Day two of Heidelberg Innovation Week: The Smart Print Shop- Enabling mid-sized printers with a competitive edge

Day two of the Heidelberg Innovation Week 2020, Christine Kaser, product manager at Heidelberg, explained how the Prinect workflow system provides a higher level of flexibility and profit margins for mid-size printing companies.

21 Oct 2020 | By Abhishek Muralidharan

According to Christine Kaser, the Heidelberg Prinect workflow system equips mid-sized firms to compete with bigger industry players. She said, this is because in the present times, digitising processes truly pays off. “Converting manual to automated processes helps printers to boost their flexibility and profits - immediately. The key elements of navigated printing, clearly defined workflows and consistent operator guidance throughout the printing process eliminates errors, ensures process safety. Also it boosts production time,” said Kaser.

This system not only deals with the print accessories but also helps in the optimised functioning of a range of presses such as the Heidelberg Speedmaster CX 75. By equipping these offset presses to produce short-run jobs, Prinect helps print businesses to become more efficient. “Our workflow system enables the Speedmaster presses to function on our ‘push-to-stop’ principle, where the machine performs all processes automatically and navigates the operator whenever a manual intervention is necessary. Thus, the printers benefit from smart production and minimised downtime,” she added.

In addition, through a new multi-touch screen which can be equipped with any press, the operators can get a clear overview of all the print processes. The screen displays instructions on which steps to perform next. Then with the help of Heidelberg’s patented technology Intellistart 3, gives precise control to the operators. “This new user interface has a truly intuitive design akin to our smartphones. This modern user experience on high-tech machines turns the pressroom into an attractive workspace for the younger generation.”

The entire process information is available in real-time on the mobile app or any such integrated device, through which the operator can prepare and release up to 10 jobs during the production run; while a range of assistant systems is available to relieve the operator of routine tasks. One such assistant system is the Colour Assistant Pro which ensures high-speed colour changing capability.

Prinect also integrates the entire post-press in its workflow. For instance, for the optimised functioning of the Polar cutting machine or the KH 82 folding machine. “Our systems enable machines such as the KH 82 to run with a high degree of automation,” said Kaser.

To sum up, the Prinect workflow systems are "the best fit" to achieve the flexibility that a medium-sized printing firm needs. "It helps avoid costly errors while ensuring maximum performance without excessive strain on the operators. And all this is available at a convincing price-performance ratio,” she concluded.

See All

See All