Narrow-Web Flexo Press 2020: Gallus

PrintWeek featured 12 overseas and seven Indian manufacturers of narrow-web flexo printing presses. Rahul Kumar spoke to multiple machine manufacturers and suppliers, who said the market is picking up.

Here we feature one such company's presses from our top picks - Gallus

16 Nov 2020 | By PrintWeek Team

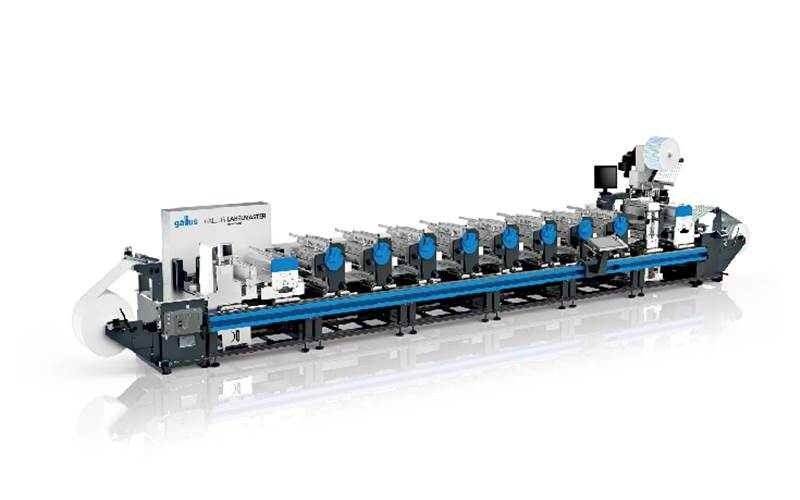

LABELMASTER 340/ 440

The Gallus Labelmaster 340/ 440 offers less complexity, a unique and perfect price-performance-ratio with the well-known Gallus quality and delivers the highest cost-effectiveness in the label printing industry. It meets all popular needs on the market, and depending on the model line, modules can be freely selected and configured, thus enabling the press to be customised to suit any requirements. The machine with printing width ranging from 340 to 440-mm, can print self-adhesive labels, paper, cardboard, monofoil label materials, and tube laminates. Its short web path minimises material waste and its servodriven and gearless anilox rollers can deliver precise and stable register accuracy across all printing speeds. The Gallus Labelmaster 440 has been installed at the Avery Dennison Innovation and Knowledge Centre (ADIKC) to support all necessary training and knowledge sharing sessions jointly operated by Heidelberg India and Avery Dennison.

ECS 340

LAUNCH

Labelexpo 2010.

UTILITY

Equipped with cutting-edge technologies, Gallus ECS 340 is configured for outstanding operational efficiency. The combination of integrated direct servo drives and automation functions such as presetting, format length correction, job data storage and recall, register control and dynamic print pressure adjustment is unique. All these elements work together to safeguard the outstanding productivity of the Gallus ECS 340 and ensure it delivers consistent, easily reproducible quality of the highest standard.

POPULARITY QUOTIENT

Gallus ECS 340 is the bestselling press in its class as it can handle various print applications from labels, tubes laminates, aluminum foils to unsupported films. As per need of the print segment, the machine can be configured to print and process the jobs in-line.

See All

See All