Barcom reduces ink-related waste by 80%

Vasai, Mumbai-based label printing firm Barcom Industries has reported significant reduction in ink-related waste and improvement in quality consistency after installing a Colorsat Match automated ink dispensing system from GSE Dispensing along with a Perfect Proofer tabletop proofing system.

22 Oct 2018 | By Abhishek Muralidharan

Vasai, Mumbai-based label printing firm Barcom Industries has reported a significant reduction in ink-related waste and improvement in quality consistency after installing a Colorsat Match automated ink dispensing system from GSE Dispensing along with a Perfect Proofer tabletop proofing system.

Barcom operates eight Mark Andy flexo presses and also India’s first Mark Andy Digital One press. These presses, combined with a full range of finishing processes and special effects capabilities enable it to handle production runs from 5,000 to 10 million labels for its customers.

Prasanna Sahu, managing director, Barcom Industries, said, “With more and more presses and rising customer demands, ink formulation that is accurate, consistent and timely is very important.”

Explaining the tedious job of meticulously matching the colour and the challenges associated with it, Sahu said, “We were doing all the formulas and recipe-making manually using Pantone formula guides and ink suppliers’ databases. While we were eventually able to meet the required colour targets, this method of colour matching resulted in a high level of waste. It resulted in the loss of leftover ink after every job that was virtually impossible to reuse in new recipes. It was also time-consuming and labour-intensive and made stockholding a complex affair.”

Sahu realised that efficient ink logistics is a way of saving time, money and waste, as well as creating the capacity to handle more and longer jobs with minimum delay. He found a solution in Colorsat Match ink management system from GSE Dispensing and a Perfect Proofer from GSE’s affiliate company, Print Proof Solutions.

The Colorsat Match dispensing system can be used for flexo, gravure and screen inks and will automatically mix precise formulations and quantities in minutes. The easy re-use of press-return inks improves ink yields, and the system contributes to a cleaner ink kitchen and improved stock management. From up to 20 base colour components, the Colorsat Match can calculate the exact colour and ink volume required for the job and dispenses it in minutes.

“On average, we mix 2,000 to 2,500kg of ink each month,” said Sahu. “Since installing Colorsat Match, we have better control of waste and have cut our ink waste from five per cent to about one per cent. That’s an 80 per cent reduction.

“Other advantages include ease of use for the operator, user-friendly software, barcoded job tickets, increased control of ink use and inventory, and automatic cleaning,” Sahu added. “Colour matching repeat formulations is easy and accurate.”

Barcom has deployed a closed-loop system for achieving colour quality with the help of the colour formulation software, the dispenser and proofer. The colour formulation software generates the recipe, which is received by the Colorsat Match dispenser’s ink management software, and a small quantity of ink is dispensed. A draw-down is then taken on the Perfect Proofer, to compare tonal gradations with those specified in the job card. If the result is correct, the formula is saved to the system. Otherwise, the necessary ink formula adjustments are made, an extra ink component is added at the dispensing stage, and the result is finally checked with the proofer. The recipe is then stored for easy recall on the database, enabling any repeat orders to be prepared correctly at the first attempt.

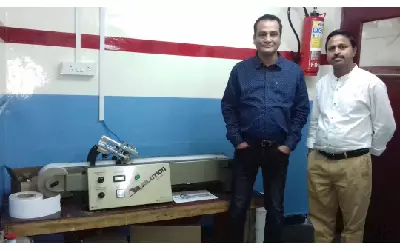

Prasanna Sahu, chairman Barcom Industries, Rajesh Gawde, director, Arcadia Associates, with the Perfect Proofer (l-r)

“Using the Perfect Proofer, we can mimic the characteristics of individual presses: anilox, plate characteristics, speed and pressure,” Sahu explained. “We can proof jobs before printing without having to ink-up the press and use press time. This is especially good for long runs, and we can also proof jobs in advance, saving time and money.”

“We are seeing tremendous monthly ink savings and have significantly reduced ink preparation time. Our ink kitchen is clean and well-organised and we have reduced the storage space. At the same time, we have increased press capacities, and experienced easy repeatability of accurate formulations,” Sahu concluded.

Established in 2004, Barcom employs more than 200 people at sites in Vasai and Mumbai, with a further facility under construction in Odisha. In addition to labels, the company manufactures tags, pouches, and speciality products including barcode, QR and security labels, and re-closures, with annual revenues of Rs 75-crore.

GSE Dispensing is represented in India by Arcadia Associates, based in Mumbai.

See All

See All