Bobst signals India shift with India-built NovaFFG 1024

At its first flexo folder gluer open house outside Europe, Bobst put the spotlight on its made-in-India NovaFFG 1024 and the region’s growing role in corrugated board packaging. Prabhat Prakash and Sai Deepthi report from Bobst plant in Pirangut, Pune.

17 Jun 2025 | By PrintWeek India

The 16 May VIP Customer Day at Bobst’s factory in Pirangut marked a first for the company as it showcased its NovaFFG 1024 flexo folder-gluer (FFG) line in a live demonstration outside Europe. The event placed the spotlight on the machine’s performance, automation features and relevance to India’s fast-growing corrugated segment. The NovaFFG 1024, manufactured at Bobst facility in Pune, delivered an output of 18,000 boxes-per-hour during the demo. Two jobs were completed within 30-minutes, with a job changeover clocked at under five minutes.

Bobst NovaFFG supports a bottom die-cutter for simple die cuts like flap cuts, hand, and vent holes, but the key feature remains its robust slotter section with four pairs of shaft, and three pre-creasers combined with independent shaft for glue lap cutting ensuring clean cut and waste ejection and the unique servo-driven folder section which ensures perfectly square folding with minimal fish tailing and consistent gap which is one of most critical parameters of Regular Slotted Container (RSC) box quality. While the upstream section is mechanical driven, the downstream section of the folder and top the counter ejector is servo-driven.

Print registration is managed by motion controllers requiring minimal calibration. The NovaFFG1024 also features a dust collection unit to ensure print clarity and consistency. Bobst states the line can process up to 1,360 bundles per hour under optimised cycle conditions. Feedback from the first two customer installations in India has been described as “positive” and customers praised the machine to be user-friendly, easy to run, easy to set up thanks to intuitive Human-Machine Interface (HMI).

Venugopal Menon, zone business director, BU printing converting - Indian subcontinent at Bobst, presenting at the VIP Customer Day, emphasised the strategic growth potential of corrugated board packaging in Asia. “The corrugated industry is estimated to become USD 278-billion by 2029, with the Asia-Pacific region expected to be USD 135-billion. With per capita in India at 3.7-kg for corrugated kraft with comparison to 35.3-kg in China and 18.7kg in Indonesia we have a potential for growth in the coming decade.”

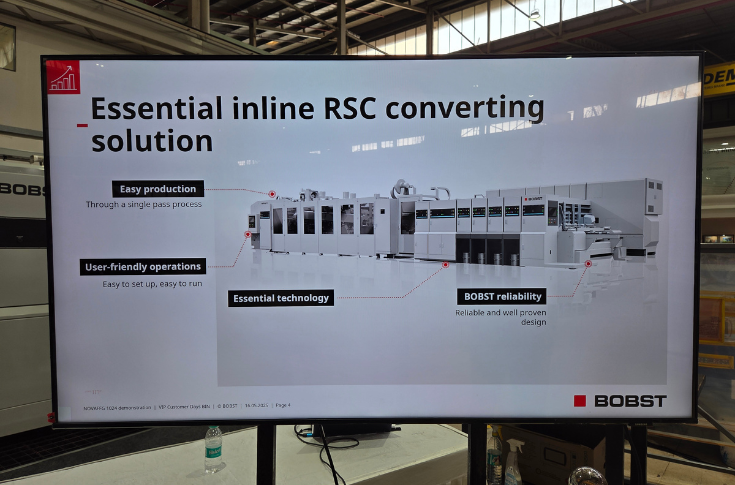

Menon added that NovaFFG 1024 delivers “high productivity, excellent slotting and folding, and a better ROI”, aimed at customers who want to grow and automate their production process with inline operation. He confirmed Bobst is planning to introduce its VisionFFG range by late 2026 to further expand the portfolio.

The NovaFFG’s compact footprint was positioned as another benefit, particularly for converters facing space constraints. “It reduces space requirements while maintaining high output,” Menon said, adding, “And tackles key pain points in corrugated board packaging of faster job turn with quick changeover, minimise manpower, reduce wastage, ensure top folding quality, negligible calliper loss and easy to operate and maintain machine.”

With production of the NovaFFG 1024 now shifted to India, Bobst is reinforcing its confidence in both the local market and manufacturing capabilities. The strategy also reflects a broader intent to address mid-tier converters’ needs, where demand for

affordable automation is increasing.

“The NovaFFG 1024 and upcoming VisionFFG are especially engineered for converters who need speed and accuracy but at a cost-effective scale,” said Menon. “These customers are serving fast-moving industries like food, beverage, eCommerce, FMCG and retail, and they need equipment that can keep pace with changing market needs, reduce cost of production without compromising on quality and consistency.”

Bobst is expanding its market with the NovaFFG 1024 and VisionFFG product lines, targeting mid- to large-scale brown box converters seeking high-speed automation at an affordable price. This expansion aligns with a projected 7 to 8% CAGR growth in the corrugated board packaging industry 2024-2029, with Asia Pacific estimated to contribute the max growth compared to other geographies in the coming years.

See All

See All