Ahmedabad-based Pentaflex wins Kodak silver award for Ankur Salt pack

Ahmedabad-based Pentaflex Films, a sister-concern of Ikon Multipack, has bagged a silver award with highest honours at Kodak’s Global Flexo Innovation Awards.

18 Mar 2019 | By Rushikesh Aravkar

Of the 200 entries submitted by over 100 companies from 26 countries, Pentaflex is the only Asian company among the 12 winners, which have cleared at least two out of four categories of innovation excellence laid down by the jury panel – creativity in graphic design; conversion from other print processes; workflow efficiency; and commitment to sustainability.

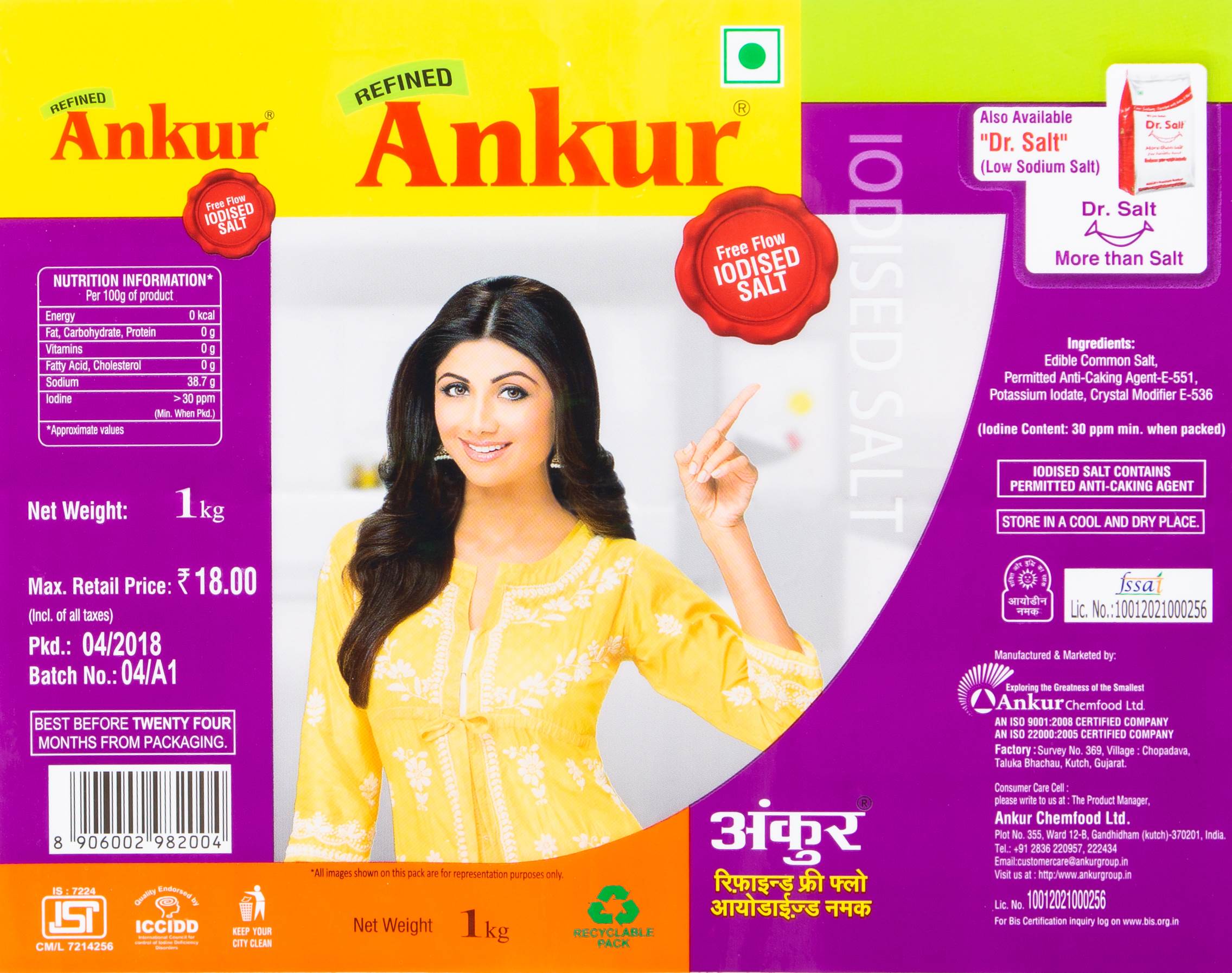

The winning entry is a CI flexo printed PE+PE laminate for Ankur Salt. Salt is traditionally packaged in a PET+PE structure for ease of printability and quality of gravure printing on PET.

Speaking to PrintWeek India and WhatPackaging?, Anand Patel, director, Pentaflex, said, “Very few companies are a step ahead of the government regulations. Ankur Salt is one such company which has switched to a 100% recyclable packaging material. While some brands have partially implemented the PE-PE laminate, many small players have shifted from PET+PE to surface-printed PE film similar to milk packaging.”

“We were able to offer them superior print quality with CI Flexo nearly indistinguishable from tradition gravure job while maintaining the visual appeal of the pack and making it recyclable,” added Patel.

The challenge, according to Patel, was to replicate the print quality especially halftones and lustre that can be achieved on a reverse-printed PET film with gravure on a reverse-printed PE film on CI Flexo.

Patel added, “Secondly, there’s a lack of data on how CI Flexo inks will react with the adhesive during lamination. So we experimented a little before we zeroed down on process parameters and choice of inks and adhesives. The print layer is sandwiched between the two layers of PE.”

“It was a joyous moment for the entire team when we got to know that we have won the Kodak award. We are a young company, which initiated operations with a CI Flexo press, we do not have experience in gravure and that’s also the reason why we constantly experiment and try to do things differently. Many a times, we fail, there are disappointments. Therefore, winning an award is an encouraging pat on the back. It is confidence-inducing and motivates the team to strive for innovation.”

Established in 2017, Pentaflex Films has invested in a five-layer poly-olefin dedicated PE blown film line from Kabra-Gloucester (USA) and Bobst CI Flexo (Germany) eight-colour CI Flexo press, anticipating the need for sustainability in the coming years. “CI Flexo is most suited to print complex jobs on PE. Keeping that in mind it is our constant endeavour to convert any possible jobs from PET+PE laminated structure to all PE structure without affecting the shelf life of the product,” concluded Patel.

Pentaflex Films along with Ikon Multipack has a blown film capacity of 700 tonnes per month and printing capacity of 500 tonnes per month.

At the helm of Pentaflex: (l-r) Anand Patel, Mukesh Makwana, Darshan Patel

See All

See All