The reinvention of Magic International’s print legacy

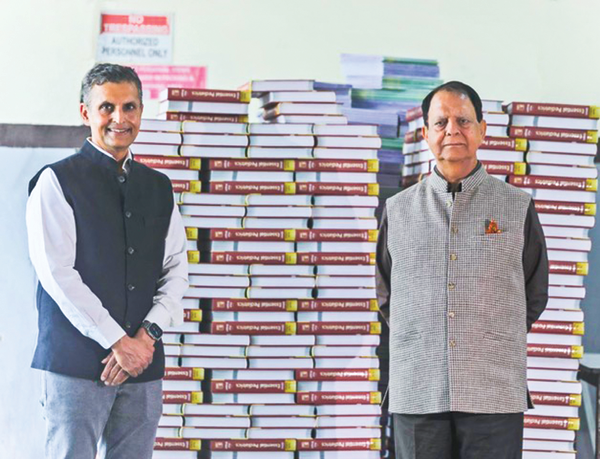

With roots dating back to a small Delhi press, Magic International has grown into a book and stationery powerhouse. Now operating in Greater Noida, the family-run business blends scale, and innovation to meet both domestic and global demand. Ashish Batra, the executive director of the company talks to Rahul Kumar and Treya Sinha

15 Jul 2025 | By PrintWeek India

In a vast factory spread across two-and-a-half lakh-sqft in Greater Noida, thousands of sheets of paper are transformed into neatly bound books and notebooks. This is the home of Magic International, a third-generation printing and stationery company that has evolved into one of the region’s most promising players.

Magic International was founded in 1991 as Surya Print Process in Delhi’s Kirti Nagar, the company began as a print shop servicing local demand. Today, it operates from a three-floor unit equipped with machinery which permits exports of 40% of its products to the international markets.

At the helm is Ashish Batra, the executive director and third-generation printer. The family’s legacy in printing dates back to the 1950s. “What began as a modest print setup is now a full-scale manufacturing unit,” says Batra. “We’ve had to adapt continuously to meet the demands of both Indian and global markets.” Batra manages the company alongside his father, Rajeev Batra the chairman of the company.

The company started book printing in the 1980s. Prior to that, it focused solely on binding. After televisions became common in Indian households, a lot of commercial print jobs were lost and the company segued into book printing with newer machines. Today, the company is an original equipment manufacturer for companies like ITC.

Two lakhs books per day

Magic International’s pre-press division boasts a Kodak platesetter that feeds plates to an array of multi-colour offset presses. These presses form the backbone of its book operations, delivering high-resolution, colour-accurate output. Ruling machines further support stationery production, while notebook manufacturing is powered by heavy-duty kit from other companies.

“We maintain an equal balance between book printing and stationery manufacturing. There is a 50-50 division,” Batra explains. “The infrastructure allows us to be agile. Whether it’s a large-volume schoolbook order or a premium stationery export job, we can depend on both for sources of income.” This flexibility has helped Magic produce approximately 2,00,000 books each day in sewn and perfect bound, hard cover or wire bound style, all put together. While some of this is destined for domestic publishers and private educational firms, a significant portion caters to international clients.

Batra’s core philosophy when it comes to running the company is simple: to grow and prosper as much as possible. “This is what we believe in as a Punjabi family. Much of the credit would go to our grandfather who started the business; a liberal Arya Samaj with an open mind. He believed in modern technology and installing new machines which is what inspires us even today. He installed the first few machines for folding and section sewing which used to be done manually at the time,” he says.

Quality shapes the mindset

India and China dominate the global stationery supply chain. Yet, according to Batra, the issue has never been volume, but quality. “Quality is the biggest concern in this industry. The international market doesn’t compromise. You’re competing with the best in the world, and so you must match those standards,” he says.

To achieve this bar, Magic has invested heavily in automation and standardised processes. Also it continuously experiments with new formats and designs to stay ahead of seasonal cycles and shifting demand. “Educational books and notebooks are seasonal, so we constantly innovate. We’re always looking at ways to create new products, whether through binding techniques, finishes, or formats.”

This innovation mindset is vital in export markets, which demand consistent quality, timely delivery, and competitive pricing. “We export a great deal of our production, and we’re present in the Middle East, the USA and the UK. International standards are non-negotiable.”

The company’s envelope range includes both gummed and clasp envelopes, made to the specifications of British and American standards, and commonly used in commercial correspondence and institutional mailings. The company’s ability to meet the quality expectations of demanding export markets like the USA underscores its international credibility.

The magical touch

While the machines hum with the precision of a modern factory, Magic International remains deeply human at its core. Its leadership, built around the Batra family, brings decades of experience and a hands-on approach to the factory floor.

Rajeev Batra Ashish’s father and the chairman of the company serves as an inspiration to him. “He is the kind of person who can tell if a press is misaligned just by listening to the sound emanating from a running press,” Batra says. He credits him for helping modernise without losing a personal “magical” touch.

“Being a third-generation printer means you inherit a lot of knowledge, as well as also responsibility. We’re not just running a business; we’re continuing a legacy,” he says.

This legacy isn’t only about family. Many of Magic International’s 150+ employees have been part of the team for over a decade or two. And this team is trained across various functions to ensure consistency and productivity.

“We’re keen to employ women and aid in the mission of women empowerment. It feels like we are lending a hand to people who need it the most.”

“Empowerment doesn’t always begin with big titles, it starts with opportunity,” says Batra, “Small roles in binding or quality checks can make a real difference to a woman’s life. That monthly income, however modest, often supports school fees, medical bills, or daily household needs. We’ve seen firsthand how financial independence, even in small steps, boosts confidence and uplifts entire families. Even in the lean business season, we keep the women around, purely to give them a confidence boost and maintain their income continuity.”

Constant upgradation

The company adds and replaces machines fairly frequently, as customer needs evolve with time. Recently, it purchased two Komori presses with a four-colour configuration, GL 37s, which Batra says is ideal for book printing.

It has also invested in envelope machines, which can produce about five million per day and has a full inline packaging system for this production to maintain seamless supply to the customers.

At the heart of Magic International’s book printing and stationery production setup is an integration of well-designed balance of press and post press machinery, allowing the company to cater efficiently to both Indian and international markets. The company has invested in advanced equipment from ECH Will and Kugler Womako, a German manufacturer known for its high-speed ruling and binding systems.

These machines form a critical part of the notebook manufacturing line, enabling precision, consistency, and automation in the production of notebooks. The ECH Will machines are particularly valued for their ability to handle large volumes without compromising on quality, a necessity for a company that deals with significant seasonal demands.

Complementing this international setup are nine Heidelberg presses in varied configuration to print and deliver quality books and stationery items. A battery of binding machines from Kolbus and Muller Martini help shape the final products that are made at Magic; be it books, journals, notepads or spiral bound notebooks.

The growth story

Magic International reports an annual growth rate of 20–25%. Despite this, Batra is clear that growth isn’t just about numbers. “We want to grow sustainably. That means improving processes, upskilling our workforce, and upgrading technology, not just expanding for the sake of it,” he says.

Environmental concerns are making their way into the company’s roadmap. While the industry as a whole has been slower to adopt green technologies, Batra is optimistic. “There’s growing awareness, especially among international clients. We’re exploring recycled paper usage, energy-efficient kit, and waterless print solutions,” he says, adding that most of its paper is FSC-based. Batra has emphasised Magic International’s commitment to environmental responsibility, particularly through the installation of an effluent treatment plant (ETP) at the Greater Noida facility as well as the installation of solar panels.

By prioritising the ETP, Batra underlines the firm’s belief that sustainability is not an option but an operational necessity. The installation ensures that water discharged from the printing process meets environmental regulations and minimises impact on local ecosystems and communities.

The future for Magic International is promising. With a solid domestic base, and export outreach, and a facility designed for scale, the company is well-positioned to expand further. Batra hints at plans for diversification and more automation, possibly even digital printing capabilities for short-run, high-quality jobs.

For now, the focus is on staying consistent and customer-centric. “In printing, there are no shortcuts. Every sheet matters. Every detail shows. That’s how we operate, and that’s how we’ve earned the trust of our clients over the years,” he says. Batra’s advice to today’s entrepreneurs is simple: start from the roots, be honest and work hard. “Things will eventually pan out if one sticks to these three principles, and it is what counts.” In an age where screens dominate and paper is often seen as part of a bygone era, Magic International stands as a quiet but determined reminder that ink-paper, craftsmanship can still weave their magic wand.

See All

See All