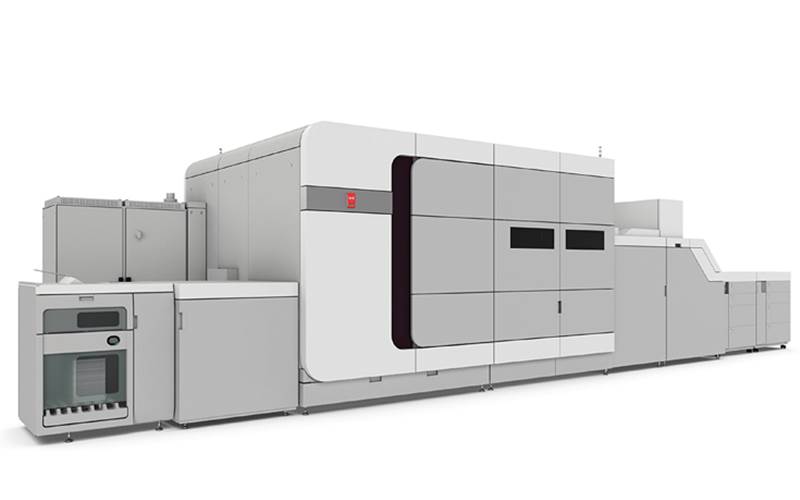

Product of the Month: Canon Oce VarioPrint i300

Puneet Datta, senior director for sales and marketing at Canon India, says, the VP i300 allows users to print on low cost media such as offset coated and uncoated stocks and can achieve a higher print quality

29 Mar 2019 | By Rushikesh Aravkar

What does it do?

High-speed inkjet. Now on sheets. It is a highly innovative, high volume colour inkjet sheetfed press that combines the proven inkjet advantages of high productivity with sheetfed versatility and media flexibility in B3 format. It comes with the ability to print on both offset grade uncoated and coated papers. It is also capable to print on inkjet coated / treated papers which shows even better print quality.

When was it launched and what market is it aimed at?

During its launch at Drupa 2016, the i300 was the worlds’ first B3 sheetfed inkjet press in the market.

Initially, the target applications were ‘transactional documents, direct mail and book publishing’, but with the latest introduction of new set of pigment inks it can now target the ‘commercial print market’.

It can be deployed at an offset printing environment where there is a need of shorter runs, variable printing with high quality.

In India, the sales of i300 was announced during BMPA’s Print Summit 2019 with the display of print samples at PrintPack 2019.

How does it work?

We have incorporated an intelligent duplex system with full-width head arrays of variable drop inkjet heads. The print heads are adapted from the proven Oce Color Stream continuous feed inkjet press which uses piezoelectric print heads with Digi dot technology. These heads produce multi-level dots with variable drop size results in perceived 1200 dpi print quality. The i300 system comes with a standard CMYK plus one additional station which uses “Color Grip” as a priming liquid before CMYK printing for higher print quality on offset coated papers.

The printhead nozzles are monitored through an inline inspection system which automatically detects and compensates the nozzle failure on the fly without stopping the press.

The press is configured to automatically inspect the paper input at full speed. Before the printing process, it detects and purges any sheet which is deformed / imperfect for printing without a press stop. With this kind of automation, i300 can run with high uptime resulting in maximum utilisation of the press capacity.

Explain the functioning of ColorGrip.

ColorGrip lays drops of priming liquid underneath drop of a colour ink. This printing method means that the i300 can handle a wider range of papers. ColorGrip enhances the image quality on papers which are not designed for inkjet printing, giving these papers a print quality at par with the inkjet treated stocks which are usually more expensive than the offset coated stocks. This will enable the users to achieve the quality of an inkjet treated stock with the paper price of an uncoated offset commodity stock. ColorGrip also expands the media range to include some offset coated stocks. The printer has the ability to automatically adjust the print parameters for each media type on a sheet-by-sheet basis.

What are the inline finishing options available with the i300?

The i300 is designed to be field upgradable to new features as and when released. There are a number of inline and near-line finishing options available for various applications and desired output such as inline perforation, inline slitting and offset stack out for books, inline booklet making and many other options depending on the application.

How productive is it?

It can print up to 300 A4 impressions per minute which can reliably output 8500 duplex A4 impressions per hour. The standard configuration of i300 has an input capacity of 4600 sheets of 80gsm. The standard paper input module has four different trays for paper feeding with adjustable sizes. It has an option to connect with three such paper input modules depending upon the customer requirement. The press comes with a monthly duty cycle of up to 10 million A4 impressions a month.

How easy is it to use?

First and foremost it is ‘Inkjet On Sheets’ and so much more easier to handle as a press. It’s also controlled through the proven Oce Prisma controller and Prisma sync digital front-end technology with a graphical user interface and touchscreen controls which make the learning curve shorter and easier when it comes to operations.

Additionally, it is compatible with many third-party digital and offset workflow platforms which makes it an almost seamless integration to ones existing workflow.

Many existing customers have borne testament to the fact that Oce VP i300 is an easy transition from toner cut sheet / offset sheetfed printing.

Specifications:

Process: Drop-on-demand piezo electric inkjet heads

Inks: Aqueous-based pigment inks

Paper sizes: From 203x203mm to 488x320mm. (With optional guide: 178x254mm. With PIM-XL: 350x500mm)

Stock weight range: 60–300gsm

Paper input module: Upto 4,600 sheets (80gsm paper) per input module with four different trays

Speed: Up to 300 A4 impressions per minute

Front end: Prismasync Controller

See All

See All