Made in India: V-shape layflat binding technology from Pinnacle Technocrats

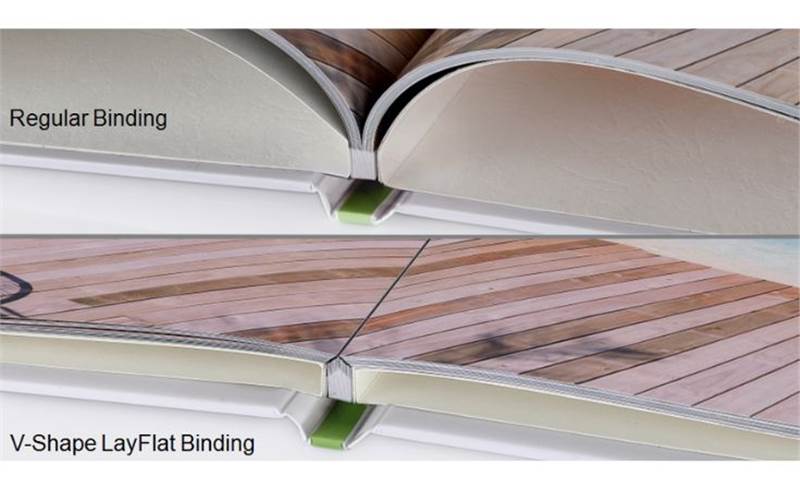

The V-shape layflat binding is a patented technology from Pinnacle Technocrats. The USP of the product is that with V-shape books open fully layflat without any obstacle in the spine area, Nilesh Parmar of Rajkot-based Pinnacle Technocrats tells Rahul Kumar

13 Apr 2023 | By Rahul Kumar

V-shape layflat binding is a patented technology from Pinnacle Technocrats exclusively used for binding double-sided prints. The company has introduced several machines to produce 100% V-shape layflat books.

According to Nilesh Parmar of Pinnacle Technocrats, the advantage of V-Shape is that it offers a versatile look to books giving the full area to print without any image/ matter loss with respect to traditional binding without V-shape.

The technology

The machines come in different variants to meet the requirements of different industries. The machines are designed to offer optimum productivity and consistency to reduce production costs, backed up by services across the globe in different customer locations.

The Adroit Z+ Auto model is an inline V-Shape binding machine that can be programmed to bind up to 10 photobooks with varied specifications.

The entire process takes place without any human intervention. The specially-designed patented technology of the paper feeder ensures that each time only one piece of paper gets fed inside the feeder. Once the programming is pre-defined for each book, Adroit Z+ Auto carries on the entire process right from auto-feeding, window-cutting, hole-punching, thermal laminating and auto-cutting of the laminated sheets with precision.

The TP 450 SLV is a multi-functional slit and strip binding machine used to give photobooks made of special media, a completely Layflat opening with V-Shape technology. This machine solves the problem that typically occurs when laminating photo books that have unique surfaces such as texture paper, metallic paper, lustre paper, and so on.

The AccuBind SW 401 takes care of all the processes involved in binding a photo book — window-cutting, creasing, hole punching and stapling. With a built-in digital micro-controller, it helps to pre-define each project and save it for later use. It also possesses a unique feature of making two creases on a single page, especially used for creasing the first and last page of the photo book.

The AccuBind Adroit 401 has the unique feature of being user-friendly in spite of having multiple uses. It executes three basic processes involved in binding; window cutting, creasing, hole punching and stapling.

All of these processes are programmed in a way that the user just has to feed the prints manually. The rest is done automatically.

This machine also helps a printer pre-define each project and save it for later use. The entire machine is operated using the touch control panel.

The market

Pinnacle Technocrats patented the technology in 2012. It first launched the basic version and gradually upgraded to a fully automatic version in 2019.

Parmar said the technology is aimed at the entire printing industry, especially those looking for a special visual book/photobook binding to give better look aesthetically and increase the media usage area, with productivity and customer delight being areas of focus.

“The Indian market is both price-sensitive and manpower-sensitive. Our technology takes care of both these issues, Parmar said, adding, “Our products are not expensive for a printer who seeks quality and productivity which cannot be achieved by manual intervention. Each product cuts the costs of at least four to six workers. So, the ROI is fast.”

He said the company’s prime customers are those who are into photobooks or visual books or wedding albums. “However, the technology can be used in various areas where appearance is important,” he added.

The company has a customer base of more than 600 printers using different models. These include Canvera Digital, Printonica, Glo Digital, Savitri, Sumalas Colour Lab, Super Photo, 3G photo, Yash Pawan Digital Press, and Green Colour Lab, among others.

Parma said an Indian customer usually looks for quality production and consistency with trusted service.

The USP

According to Parmar, the V-shape binding technology is catching up in the market. He said that the USP of the product is that the book opens fully layflat without any obstacle in the spine area. As a result, a large image covering two pages can be seen without image loss. It offers a better appearance against butterfly openings.

He added that in the technology, the window-cutting machine is integrated with a lamination machine with sheet cleaner and a cutter between sheets and stapling unit.

“There is no alternative to the technology, as we have the V-shape as patent,” Parmar said, “No other single product can do all the tasks that our products do. To match the look, you will have to use three different products from three different vendors.”

He gave the example of a customer who was earlier producing 200 photobooks using two slitting machines and four lamination machines. Now, one Adroit Z+ takes care of the entire production with just two operators against six to eight people earlier.

See All

See All