Labelexpo in Brussels has big plans as post-Covid revival bears fruit - The Noel D'Cunha Sunday Column

The Labelexpo Europe 2023 will transpire in Brussels, Belgium from 11-14 September 2023. Jade Grace, managing director for Labelexpo Global Series, says the solution to challenges lies in recognising how technologies are interwoven in the production of labels and packaging. She tells Noel Marshall D'cunha, "the Labelexpo series have been an integral part of the process"

06 Aug 2023 | By Noel D'Cunha

Noel Marshall D’Cunha (NMD): First things, first. With the per capita consumption in the Indian label industry climbing from 0.60 sqm in 2019 to approximately one sqm, the Indian label market is growing, isn’t it. We estimate it to be close to Rs 10,000-crore. You were in India recently, what are you hearing about the Indian label market?

Jade Grace (JG): Exactly as you say, we learnt that the Indian label market is booming on the back of the continued rise of organised retail, the growth of new ‘challenger’ brands and an expanding middle class with disposable income. Also, we learnt that this growth has also made the market fiercely competitive on price, leading more label converters to look at diversifying into flexible packaging and folding cartons. Labelexpo India will need to reflect this shift in the outlook of Indian label converters.

NMD: Now for a bit of fortune-telling. What do you foresee for Labelexpo Europe 2023?

JG: I believe we will achieve the 2019 show numbers. Already we have 178 first-time exhibitors booked for the show.

NMD: The previous event spanned 40,000 square metres of floor space and drew 37,903 attendees from 140 different countries across the four-day exhibition.

JG: Yes, the positivity about the return of Labelexpo Europe in September has been overwhelming. The show has been an integral part of the buying cycle. Suppliers schedule their key launches around the event date, and printers make many annual purchasing decisions during the four days.

NMD: The Indian machine manufacturers did particularly well in 2019, with UV Graphic Technologies selling seven Ultraflex UFO presses, Multitec selling its full servo S1 press to a Russian converter, and Monotech Systems selling three Colornovo presses, one each in China, Europe and Asia. These are mostly press manufacturers. What market opportunities exist for Indian label manufacturing equipment and consumables looking to sell beyond India?

JG: We noticed at Labelexpo India 2022, the growing sophistication of India’s domestic machine manufacturing industry, particularly around flexo and digital presses. This matches the growing industry requirements for more automation, faster makeready and reduced waste to combat skilled labour shortages and rising materials and energy costs. This has eaten into what was traditionally the stronghold of Western press manufacturers aimed at the entry-to-mid-level converter sector. This in turn will open up the same entry-to-mid-level markets in different developing regions such as China, the Middle East and North Africa (MENA) Turkey, and Southern and Eastern Europe. This will, however, need to be matched by local technical support and spare parts availability.

NMD: At the LMAI Conference 2023, we saw a trend prediction that seems accurate: that production runs are getting shorter while the number of SKUs is increasing. This means we're producing more labels with dynamic designs that add value. Traditional printing methods like gravure and offset are no longer the best options. New technologies like digital, flexography, letterpress, and combi presses are now available.

JG: From its earliest days in the 1970s, the narrow-web label industry has always been about ‘horses for courses’, using the most appropriate press technology for the task at hand. For example, when letterpress and offset were the dominant print technologies (outside the US), they were always used in combination with other processes – flexo coating, rotary screen and hot foiling for example.

NMD: Which is superior? Is this question even relevant?

JG: When flexo became the dominant narrow-web print process, once again, it was used in combination with a wide range of other processes, including gravure on the same press line.

NMD: What about digital presses?

JG: With digital, we have seen the same thing. Not only are digital presses incorporating flexo press print and converting components, but also flexo presses being fitted with digital print bars for variable print or to add digital whites or spot colours. So the answer to your question is converters will continue to specify machines which use the best of each process to achieve optimum added value results.

NMD: Noted. Can you update us about the latest numbers from the show in terms of exhibitor numbers?

JG: At this year’s Labelexpo Europe in September, we will have over 600 exhibitors across four days.

NMD: Are you expecting more launches?

JG: We expect to see countless new product launches at this year’s Labelexpo Europe - we now have over 300 so far, which is incredible.

NMD: Which are some of the product launches you think will be key to the labellers? And why?

JG: Labelexpo Europe will see the global launch of two new digital presses intended for flexible packaging production. This will be a key for label converters looking to enter or expand their production into flexible packaging.

NMD: For example?

JG: HP Indigo launches the 200k mid-web press, the successor to the hugely successful HP Indigo 20000. HP will also run a ‘digital pouch factory’ ecosystem demonstrating pouch manufacture and finishing of other unsupported films, including shrink sleeve labels.

NMD: And the second digital launch?

JG: Xeikon marks the global launch of its TX-500 digital press, which uses the company’s Titon toner technology to print on paper pouches without needing a protective varnish (this will be the press on Automation Arena). Xeikon also launches its Quality Measurement Module (QMM), which can optionally be fitted on all Cheetah 3.0 CX Series presses and is responsible for monitoring density and registration throughout the print run.

NMD: Any new technology that’s significant?

JG: A new wave of water-based inkjet technologies for flexible packaging will be launched this year, with Screen showing its Truepress Pac520P press printing on paper pouches for the first time at a Labelexpo show.

NMD: While labels remained central to the Labelexpo experience, the 2019 show floor reflected its continued diversification into flexible package printing with a wider appeal for brand owners and wide web converters.

JG: As we noted above, we see a major trend towards interest in flexible packaging among Indian label converters. This is part of a trend we see across all our global Labelexpo shows.

NMD: Will that trend continue?

JG: We have introduced a flexible packaging trail at Labelexpo Europe 2023 which will allow the show visitors to examine both digital and conventional press technologies, flexpack material constructions, coating, laminating, ink and curing requirements, in-line and near-line decoration options, QC and migration testing.

In addition, there will be a dedicated Label Academy flexible packaging masterclass, which will include a presentation on the current status of the UVFoodSafe project.

NMD: Interesting ...

JG: Yes. We will see similar trials taking place at future Labelexpo shows in China, India and the US.

NMD: While we are talking about flexible packaging, the 2017 edition saw Labelexpo Europe moved from being ‘label only’ to packaging. Then in the next edition of flexible packaging? Was that move productive for the visitors?

JG: At all of our Labelexpo shows globally, we ask our visitors about what brings them to the show, and since we started promoting package printing technologies back in 2017, we have seen a spike in visitor interest in flexible packaging.

NMD: An interesting example of ‘chicken and egg’ - and what comes first?

JG: Show visitors are becoming more interested in flexible packaging because there is a demand from their customers. At the same time, Labelexpo is stimulating that interest by increasingly focusing on flexible packaging exhibitors and educational events.

NMD: Is folding cartons next after flexible packaging?

JG: We will have to see what the market says. It is worth bearing in mind that we are interested mainly in the shorter run, added value segments of the wider package printing market, and viable short-run added value finishing equipment is a key part. Once those developments take place in the folding carton market, I’m sure Labelexpo will be open to a move in that direction – towards a comprehensive package printing show.

NMD: What is the status of stand-alone flexo? Is it on the wane?

JG: In a word, no.

NMD: But there were no flexo presses at Labelexpo Americas 2022?

JG: It was a temporary blip. This was mainly due to supply chain issues in the post-Covid months.

NMD: Will Labelexpo Europe 2023 turn the tide?

JG: The show will see a major resurgence in flexo. There is a trend towards wider, mid-web (26in) presses which are really designed for all packaging substrates including flexible packaging and folding cartons as well as wraparound and shrink sleeve labels.

NMD: Which are the companies to display these presses?

JG: Nilpeter, Bobst, and Lombardi will all show this width machine. Then you will see the highly modular, fast-process change OmetKFlex series, Etirama and Mark Andy with brand new flexo press lines and a host of ancillary equipment, including new direct exposure flexo units, LED-UV curing and fast, inline semi-rotary die cutting.

NMD: The converters' three common challenges: What tech to invest in? How does one cater to short- to medium-run jobs? And how does one provide embellishments in short-run jobs? Will the labellers get an answer to these common challenges at the Labelexpo Europe 2023?

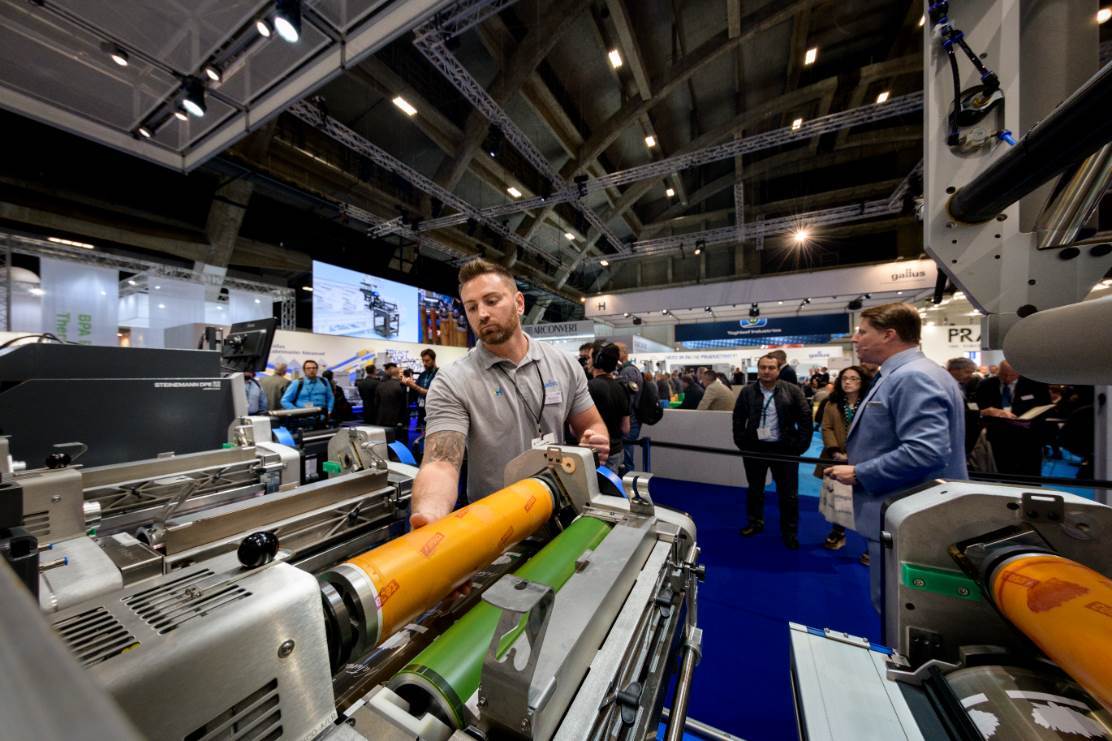

JG: Labelexpo is the ultimate show for running machinery demonstrations, so it’s a fantastic place for label converters to survey the whole machinery market and decide on their investment strategy.

NMD: But the cut-off point between digital and flexo for shorter runs is constantly shifting?

JG: Yes, but then modern automated flexo press technology, along with extended colour gamut printing, has made flexo more competitive on short to medium runs, particularly on repeat jobs, while digital presses are getting wider and faster with better, more opaque whites, and access to digital embellishment technologies which shorten makeready times on shorter run jobs while adding the possibility of highly complex personalization. Converters will choose to mix and match between these options.

NMD: According to the Finat Radar Report released early this year, for 2022 as a whole, European self-adhesive label stock demand decreased by 4.7% compared to 2021. Has the situation improved? What was the cause of the volatility?

JG: This dip in label stock demand is mainly attributed to de-stocking by the major brands. During the massive post-Covid supply chain blockages, including the Finnish paper strikes, brands built up buffer stocks. In many cases, so did the larger label and packaging converting groups. There are already signs that label consumption volumes are picking up in Q1-2 2023.

NMD: What are the concerns, and way forward?

JG: Currently in Europe, there are major concerns about high inflation, high-interest rates, low growth and looming recession, but the label industry has always remained remarkably resilient even in challenging economic times, and as said above, early signs for 2023 growth remain encouraging.

NMD: Flexible Packaging Arena was among the two new additions to the Labelexpo Europe 2019 highlights. How successful was it? What was special about the two events?

JG: Yes, the Flexible Packaging Arena was very successful in 2019, demonstrating to label converters how they could diversify into the growing niche of flexible packaging. It helped provide an understanding of the kinds of materials which constructions used, the optimum web widths for wider format packs, and how to judge different ink and curing systems.

NMD: I am sure there will be a lot of talk on sustainability?

JG: Sustainability will be a key focus at Labelexpo Europe, driven by EU mandates for a circular materials economy. This means packaging materials should be recovered and upcycled back into virgin-grade materials. New adhesive technologies allow labels to be cleanly removed from both PET and glass bottles enabling the containers to be refilled or the PET to be recovered without contamination from the label.

NMD: Should we expect anything new in linerless?

JG: We will see developments in linerless materials, including a new linerless system for prime labels from Avery Dennison in partnership with Bobst and Harland Machine Systems.

NMD: What else?

JG: We have our sustainable labels and packaging masterclass, where the label and other converters are looking to improve their sustainability credentials or gain the necessary technical knowledge to become more efficient with their resources.

Labelexpo Europe 2023 will feature the Automation Arena, demonstrating a ‘lights out’ workflow from digital file creation and approval through printing, metalisation and converting to turret rewind and inspection with no operator intervention. The partners in this project are Xeikon, Kurz, Grafotronic, Esko AVT and CERM, with Fedrigoni supplying the materials for high-level wine labels for this demonstration.

The Automation Arena area will host expert-led talks on extended colour gamut (ECG) printing and how to set up an IOT-based track and trace system. There will be a flexible packaging trail.

See All

See All