Chartering the course: From hot metal industry to graphic arts and packaging

These are volatile times. There’s been pressure on print ops, particularly the vulnerable ones. It’s how we respond to these challenges that define our values. Words: Amitabh Luthra

16 Oct 2023 | By PrintWeek Team

I am proud to say that we hung on, staying close to our customers in this rapidly metamorphising environment. And we have been doing so for the last 75 years.

My grandfather, the Late Salig Ram Luthra, started Shanti Type Foundry in 1948. Much earlier he had partnered with his brother-in-law (late Lala Sohan Lal Sachdev), who had established The Standard Type Foundry in 1942 in Lahore. In those days, Sachdev, ex-Punjab police, was most impressed by his father-in-law’s letterpress printing unit and felt it would be good to explore this greenfield venture. He set up many more branches in the then-undivided India.

Standard Type Foundry was India’s first homegrown competitor to foreign companies like Stephenson Blake & Co or John Dickinson & Co.

In Kolkata in the years 1948 to the 80s, Shanti Type Foundry along with Standard Type Foundry, were the largest suppliers of blank material to the other type foundries in the region.

Your author is a third-generation entrepreneur of the seven-and-a-half-decade old Printers Supply Co, and my guru was my father, the late Ashvini Kumar Luthra, who stressed the importance of being a good human first and then to excel in my chosen field. We have always believed in being partners in the growth story of our customer friends, and for us, this consultative approach has been most important.

Foundries of yore

Apart from Shanti Type Foundry and Standard Type Foundry in Kolkata, there were Eureka Type Foundry, Little Type Foundry, Letter Type Foundry, Eastern Type Foundry, Grapho Type Foundry, Friends Type Foundry, Oriental Type Foundry, Kalika Type Foundry, Sreema Type Foundry and Padma Type Foundry.

Mumbai was dominated by Ahuja Type Foundry. Chennai had the famous Norton & Co; and Delhi had Prakash Traders, Popli Type Foundry, Lakshmi Type Foundry and Kamla Type Foundry.

There were many more foundries as it was big business in those days.

I joined our family business of casting letterpress types in 1983. Please remember, it was still a sellers’ market, and the first bit of learning I was imparted: “They also serve those who only stand and wait”. And so, that’s what we did, in fact, we had buyers waiting for us from even before we rolled up the shutters for business to commence daily.

I have done it all - from packing type fonts and blank material (quotations, quads, em and en spaces - terms which shall strike no chord with Gen Z, today), how to fit the manual paper cutting machines, operating lathes in our workshop, hand-setting types to see how it was done, attending to outstation customers, typing letters and quotations on our trusted Remington. Virtually a “sakallaka vallavan” (reference to a Kamal Hassan film in 1982; it means master of all arts).

With late Jyoti Basu, the then CM of West Bengal | With Mamata Banerji, the CM of West Bengal

Let me explain what I did in those days. It used to be: start office at 10 am and attend to all the walk-in customers streaming in through the day. A lunch break of a home-cooked four-course meal with my father, grandfather and any customer who happened to be present during lunchtime was mandatory.

Our factory had a weekly off on Wednesdays. And so Sunday mornings would often see me at our typecasting machines or in the lathe workshop where we produced paper cutting machines and other sundry equipment for letterpress printing like imposing stones and proof presses which were sold across the country. We used to wind-up at 6.30 pm on weekdays and 4 pm on Saturdays.

The only travel that I was permitted was on holidays or to Pamex and later Printpack exhibitions in the other metro cities.

Cost of print and four-colour

The transition from three-colour in letterpress to four-colour in sheetfed offset was rapid during the 1980s. Even a printer with a single colour offset machine would take great pride in painstakingly producing registered prints in four-colour prints.

In 1993, we took on the distributorship of United Inks. Mind you, we were a late entrant to offset printing, which was already in its growth trajectory.

In those days, for a four-colour job the normal rates charged by any press using single- or bi-colour machines ranged from Rs 2,500 to Rs 4,500 per set for a run of 3,000 sheets. The top-end of the market was dominated by print firms in Kolkata like Art Printing House, Lal Chand Ray and NK Gossain, who were charging Rs 8,500 for a classy four-colour job on the latest kit from Man Roland or Heidelberg.

Today, 75 years on, am I pleased with the group’s overall performance? We are pleased that we have an unmatched track record. Plus we are respected suppliers of equipment and consumables to all the packaging and printing industry verticals.

But behind every success, there exists a stumble, a setback as well as a radical change of direction. The foundry was a family business. In four years, I saw the passing away of my grandfather and two uncles. Add to it my father’s failing health. Those were the darkest days for us personally as well as for the business.

My immense faith in God, my wife’s prayers and my mother’s huge confidence in me; plus a burning desire to be numero uno in whatever I do kept me going in those dark days.

That said, there was a passion to be known as the frontrunner in introducing new technology to our industry. The roots lay in the fact that our company had dithered. Like Hamlet, we had vacillated too long. To letterpress or not to letterpress? Meanwhile the rest of the world had moved on. It was an offset market in the 1980s

I was determined not to lag behind. I was always on the lookout for new technologies that could make life easier for investors in our industry.

Having seen the demise of the hot metal industry and the rise of offset, I attended industry events to scout for newer opportunities in the ocean, which became the print and graphic industry. The Late S Vijay of Shakti Udyog took me under his wing. In fact many in the industry (including the editor of this magazine) still think that I am his younger brother. He always told me: “Keep on fighting until you win”. During the course of my journey, I was lucky to come across wonderful friends within the industry who played a crucial part in ensuring my and our companies’ constant growth.

Kolkata landscape in those days

The militant trade unionism of the last quarter of the 20th century ensured the flight of industry from Kolkata. This ruined the workforce and work culture for the next-generation too.

From being the premier place to do business till the 1960s to becoming a poor country cousin was a sad journey for Kolkata. This resulted in the city’s money migrating to greener pastures. What it did result in, however, was across India, Nepal, Bangladesh, the Middle East and parts of Africa, one finds that the packaging and printing industry is marching forward on the shoulders of a highly-skilled workforce who have roots in Kolkata. These are personnel who have cut their teeth after being trained by the Regional Institute of Printing Technology in the Jadavpur University.

We have retained our office in Central Kolkata and been at the same address since 1948. We have stayed due to the location advantage, despite having considered many time moving to a larger premise outside the city limits.

In all this. There have been momentous occasions too. I was honoured to attend Sourav Ganguly’s wedding as both - the bride and groom have family steeped in the history of the print industry in Kolkata. Again during Pamex 1991 which was hosted in Kolkata I was part of the organising committee and had the pleasure of escorting the then CM Jyoti Basu to the venue.

And yes, that print job in 1983 when India won the Cricket World Cup. I remember, NK Gossain & Co printed a special picture postcard for the winning team in four-colour on a 300gsm artboard. It was a collector’s item. I had the good fortune of making friends with Mohinder Amarnath and being introduced to the entire World Cup team by him in one of their follow-up tours of Kolkata.

The Tata Steel calendars printed at Art Printing House were always a visual treat in those days; plus the annual reports for ITC printed by NK Gossain. Both were part of industry folklore and many a gupshup session at the Coffee House were dedicated to these two items .

Later, the lay-flat brochures produced by CDC Printers for the real estate majors was one big reason for the premium real estate market to grow in Kolkata.

Cut to Drupa 2004

By 2004, I was helming Printers Supply Co. Our company was instrumental in getting the hitherto totally manual and labour oriented book binding industry of Eastern India to invest in motorised machines for book sewing, stitching, folding and perfect binding.

Printers Supply was at the forefront of supplying plate exposing systems and plate processors to the fast-growing offset printing industry. It guided the budding offset packaging industry to invest in UV curing equipment along with die cutting, foil stamping and laminating machines.

I have meticulously retained my diaries since my initial years in office. In this, I kept a record of my first customers. It’s a long list in the course of our evolution from a type foundry to suppliers of flexographic presses. One trend I have noticed is. There are many multiple firsts for varying products. (Refer to box item on the previous page).

I have always believed that it’s a defining moment when your customers return to you for re-investment. It is a matter of great pride and satisfaction that 70% to 80% of our sales come from repeat business.

Our longevity and growth can be attributed to our attentive listening to our customers. We make necessary adaptations to meet their needs and offer recommendations and solutions that align with their operational processes and environment. We have a capable in-house service team, ensuring that anyone who buys from us is sure of minimum downtime on the floor. The other thing is, I am very selective about the products we deal with and only the topmost quality is curated for our friends in the industry.

At Printers Supply, we have observed that not all the companies we work with attain the same level of success. Some customers have experienced significant growth, while others have remained stagnant. The print, packaging and book manufacturing industry is dominated by technocrats. All one needs to do is listen very carefully. The problems as well as the solutions are already with the print bosses or their senior production managers. All it needs is someone to join the dots and devise an efficient solution. However, there’s no silver bullet; the key lies in identifying the most suitable approach.

.jpeg)

Once upon a time there were four sales clusters in India: Mumbai, Delhi, Kolkata and Chennai. One thing everyone realised was that these four cities weren’t fully catering to the diversity and heterogeneity of India. My experience.

Printing and packaging has always been known to be a secondary industry catering to other manufacturing industries.

While some regions have grown due to government subsidies there are other regions which have progressed due to local ingenuity, capital and resource availability and innumerable other local reasons.

Now we have major pharma hubs such as Hyderabad, Pune and Ahmedabad. Then there are the garment hubs of Surat, Tirupur, Kolkata, the erstwhile matchbox, fireworks and calendar hub of Sivakasi.

FMCG and liquor producers have their own system for sourcing packaging material as we have seen in Baddi and Guwahati and Sri City. Also, the rising cost of land and cost of living in the metro cities have played a huge role in the growth of the newer centres for the print and packaging industry.

Why Edale ...

I first met the team at Edale at Drupa 2004. However, it was not until the next Drupa in 2008 that we discussed our representation in this region.

After visiting their earlier factory at Romsey and seeing them grow into the new facility at Fareham in Southampton, I am privileged to work alongside some of the best engineering brains in our industry today.

Also, I am used to seeing machinery manufacturing factories in India, I was quite surprised to find virtually no people on the shop floor in Fareham. We would take a break from training and step out for lunch. When we returned, the print units were closer to assembly. With no people around. It was magic.

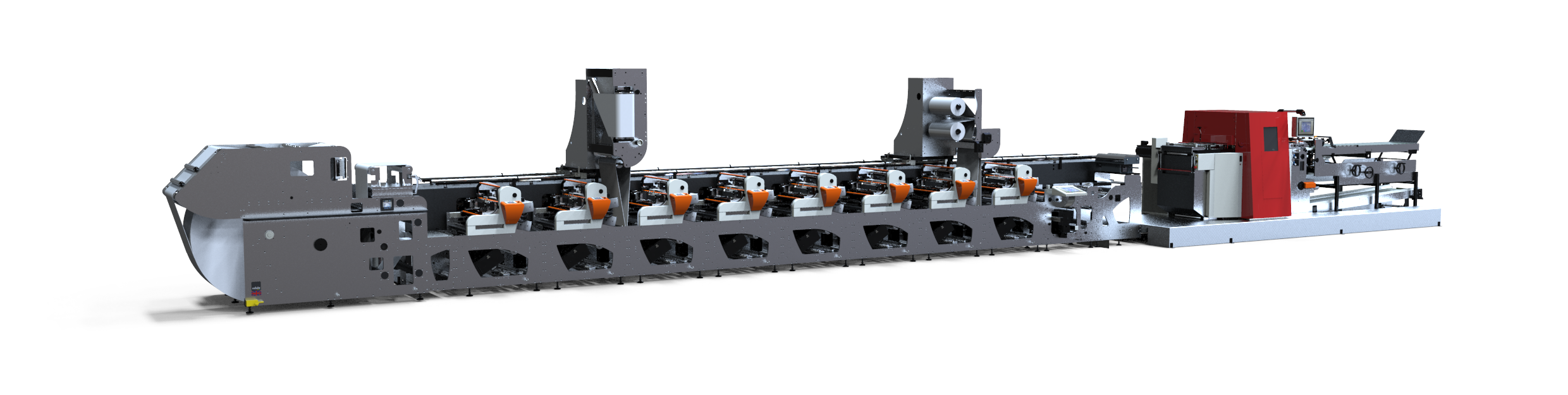

It was an eye-opener to see that Edale deployed aluminium alloy for the side frames instead of mild steel used by all other manufacturers. With 70% of their workforce being engineers, the eye for detail and quality at Edale is extremely reassuring.

There was no doubt in my mind that flexo would dominate packaging due to the ink densities and consistency in print. My earlier inninings where I was dealing with DuPont photopolymer flexo plates reinforced this belief.

My background in offset and post-press helped in the quicker adaptation of single-pass technology as I was used to seeing offset packaging units struggling with multiple machines, an army of operators and stressful amounts of work in progress. I understood Edale was a magical machine of the future.

From the first and most successful scratch card lines to producing hybrid digital/flexo presses 15 years back, Edale has had the vision to maintain a technological leadership position despite being a much nimbler company than many other manufacturers.

My initial years of promoting single-pass mono-carton production are now bearing fruit. We have multiple installations already, with more coming up this year in this region.

Worldwide, all mono-carton producers are taking a very serious look at the Edale FL 5 as being the most efficient and sustainable way of producing highly embellished cartons with one operator and in a single pass.

The fact that Edale also manufactures the most highly automated label printing machine, the FL 3, is also helping in increasing the Edale brand presence in the industry.

Next 75 years

As they say, a solid business is built by great people. All our friends in the industry - buyers, suppliers, our excellent team at all times over the years, friends and well-wishers in the industry and outside. Over and above everything, it has been God’s limitless grace.

We have played the long game. And we are satisfied. We are experiencing annual growth rates of around 40% post-Covid, and this year looks quite promising again (touchwood).

But the fire in the belly is still there for more. As mentioned earlier, there is still a lot of headspace for more growth, with our economy showing all signs of a healthy growth rate.

Next 75 years? That’s a tough one. Our founder would never have imagined the scenario we are in today. I had read a very interesting story by Isaac Asimov during my schooldays where he had written about an unfailable writing device of the future which would never lose charge and needed next to no maintenance - it turned out to be a lead pencil. So who knows?

Your mode of transport?

Have been using SUVs since 2003 and don’t think I would like to do anything else.

Your adda?

Could be in any of the heritage clubs in Kolkata in the company of close friends on weekends. Being a confirmed food enthusiast we also love frequenting various restaurants serving a variety of cuisine. Am also a member of a driving club where we go for road trips in a group with loads of masti.

Is there a shortcut to details?

There is an adage that says: the devil is in the details. Excellence lies in the meticulous exploration of details and there can be no short cut on the path to excellence.

How do you recruit?

Look for passion and honesty. Nothing else matters as it can all be taught.

What’s happening to print in West Bengal?

The scale of operations as well as growth has been much lower than the other part of the country due to obvious reasons which have been articulated by many industry leaders ad nauseam. Having said that, there is a high growth in digital print, slowing down of commercial offset, plus spike in packaging are pretty much similar to the rest of India albeit in smaller numbers.

Advice you would give your young self?

Same advice that I got many years ago: build relationships - business is incidental and will happen.

Anything else you want to add...

Be the change!

See All

See All