All about unique labels which are attractive and difficult to counterfeit - The Noel D'Cunha Sunday Column

Amid intensifying competition, manufacturers are upping their ante. Prabagaran S, senior general manager, Epson India talks about how the digital label press is poised to usher in a new era for the Japanese manufacturer. Read on...

14 Jan 2024 | By Noel D'Cunha

Rising demand for customised, on-demand label printing is changing the way businesses approach label printing. What are the factors that are driving demand?

Consumer buying behaviour has changed. Now, there are greater expectations. Consumers expect more personalised experiences when purchasing products. Brands need to adapt and offer short-run products and multiple variants of any given product to meet this demand. In addition, the market is seeing an influx of new small brands and start-ups that are introducing innovative new products in smaller quantities.

This trend is driving demand. Lastly, eCommerce is an area with a growing demand for on-demand products that can be frequently updated. These three factors fuel the demand for more customised and unique products.

Over the last eight years, the printing and packaging industry has undergone significant changes and advancements. One of the biggest trends has been the shift towards digital printing. But how does one invest in the machine of the future, keeping in mind the trends?

The printing and packaging industry has experienced significant advancements in recent years, particularly with the adoption of digital printing. However, when considering a shift to digital, consumers must ensure that the digital printer they choose addresses the shortcomings of their current analogue process. For example, a digital label press machine should complement an analogue press and bring new business opportunities for a business.

The ideal machine must offer superior printing quality, easy-to-achieve colour consistency, user-friendly operation, weather resistance, lightfast inks, no make-ready time, minimum turnaround time between jobs, easy and remote monitoring, and low power consumption. These are the key features that consumers should look for in a digital press. Epson's label press offers all these advantages compared to an analogue press, making it a top choice for consumers.

The Indian printing industry is one of the largest in the world, with a market size of approximately USD37 billion. What is the size of the label market, and within the label segment, digital label printing?

It is difficult to put a number to this. We do know that the market, while still young, is growing rapidly and has huge potential. For this reason, it will continue to grow rapidly in the years to come.

How many digital label presses have been installed in India? What are Epson’s numbers?

By our reckoning, there are currently more than a hundred digital label presses in use in India. Epson has entered this market recently and has already sold six digital label presses in India. We have a promising order book and anticipate a significant increase in demand in the coming years.

What are the latest advancements in digital printing technology that can help print service providers meet those demands? And improve the quality of prints?

The objective is constantly making labels more visually appealing and unique, so they stand out from the competition. The latest advancements in Epson label press machines include in-line varnish, which helps in embellishment work and enhances the quality of labels to a very difficult-matched level. Gloss, matte, and spot varnish are some of the additional features that can help labels stand out in the market.

Multiple-layer printing capabilities allow customers to create unique labels that truly stand apart. These are just some of the features that Epson label press users can deliver to their customers, ensuring high-quality labels that stand out in the market.

Just having digital printing capabilities does not reduce cost and increase efficiency in label customisation, the digital printing process has to be optimised. Your view?

At a basic level, analogue printing involves a 7-step process that includes making plates and dies, setting up, matching colours, printing and die-cutting, and drying ink. On the other hand, the digital printing process has only two steps: setting up a roll and printing and finishing digitally. The advantage of the digital process is significant.

What is Epson's USP?

Epson's digital press offers several distinct features to optimise the printing process. These include digital varnish, high-speed VDP (which includes barcodes, text, and images), printing speed of up to 50 meters per minute, reverse white printing capability, multi-layer printing (up to three layers), drum-type feeding units for accurate registration, food safety and no migration inks, and a total solution package that includes the printer, print head, ink, and software, among others.

What are some of the key trends in digital printing that one should be aware of?

One of the significant trends in the printing industry is the need for digital embellishment. This includes techniques like foiling and embossing, which help enhance a product's appearance and make it stand out on the shelf.

How can Epson kit help stay ahead of the competition?

Epson offers an in-line digital varnish that is ideal for this purpose. Another trend we have noticed is using variable data printing (VDP) with images. Epson has a high-speed VDP module that can handle images effectively.

How should labelers integrate digital printing into its overall marketing strategy?

To promote digital printing more effectively, converters need to leverage the concern of counterfeiting as a key marketing strategy. Marketers should also be concerned about this issue and work towards creating personalised labels that can give them an edge over the competition. By doing so, it becomes extremely difficult to create duplicates, which is a significant challenge for any successful brand.

What are some of the best practices if one has to reach the target audience?

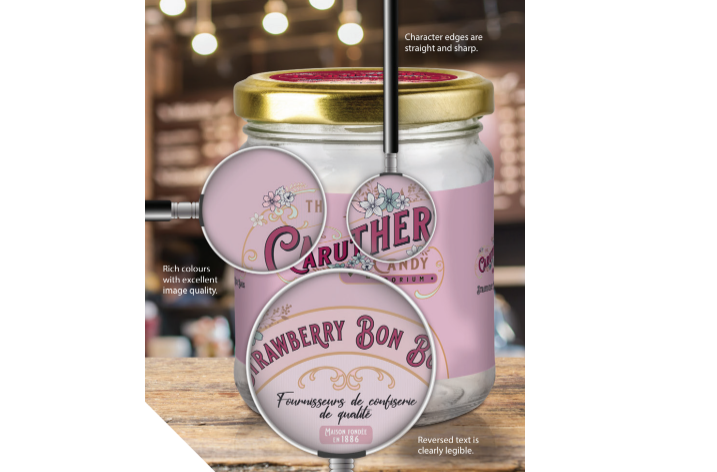

Epson's digital label press capabilities make it possible to create multi-layer and varnish effects, which can help create unique labels that are both attractive and difficult to counterfeit. RFID labels are also becoming popular in the retail vertical, and this is a cost-effective solution.

How Epson kit ensure that digital prints are environmentally sustainable and meet the latest industry standards for sustainability?

We are committed to protecting the environment, which is reflected in our corporate purpose. Our Epson Label press is made up of 30% recycled components. We adhere to strict safety standards for inks, such as FCM (Food Contact Material) Regulation, UV-Low migration inks, BS5609 - British Standard (an internationally recognised specification for printed labels, especially for marine use), UL969 certification - specific substrates (Avery Dennison US) passed, and low halogen safety standards.

Printing on difficult-to-print substrates is a challenge for labelers, particularly on digital printing machines.

Substrate compatibility is one of the key elements for any digital label press.

How does Epson presses help the labellers here?

The Epson UV press (L6534VW) can handle most standard substrates like PP, PE, PET, and Yupo-coated paper, uncoated paper, and foil. Also, it can handle substrates like polycarbonate, PVC, and shrink sleeves with a top UV coat before printing. The press can handle substrates ranging from 80 to 320 microns.

Let us talk about the other challenge: consumables.

We ensure there are no challenges whatsoever when it comes to consumables. Epson Label Press comes with an intuitive menu that helps customers carry out routine maintenance to avoid product stoppage. Besides CMYK, W, and varnish, cleaning and maintenance liquids are other consumables to maintain the optimum condition of the label press. Last but not least, Epson consumables are easily available across India, which is extremely important to ensure no downtime.

What are the key factors to consider when selecting a digital printing vendor, and should the labeller evaluate different options to find the best fit for my needs? Where does the Epson kit score on the different parameters?

A prospective buyer needs to do their homework carefully. Some of the key factors that need to be considered before purchasing a digital press are: high-speed VDP printing, QR code, barcode, batch number and image, digital embellishment with varnish capability, reverse white printing capability, multi-layer printing, consistent colour matching, and easy workflow to match spot colours (Pantone).

How should a buyer select a press?

In the final analysis, buyers should select a press that complements their existing analogue environment and helps them produce value-added labels (in-line varnish, multi-layer printing, reverse printing) to increase their overall business opportunities.

See All

See All