Utilising screens to improve whites and spot colours in high-volume printing

The importance of good white ink laydown in flexible packaging cannot be understated. A good white ink underlayer forms the foundation for most color graphics and provides the single biggest opportunity to improve their “pop.”

Without a good white underlayer, the image looks flat and lacks chroma. White represents 40 per cent to 50 per cent of the total cost of ink used, so optimising its laydown results in brighter graphics and significant ink savings.

25 Jul 2020 | By WhatPackaging? Team

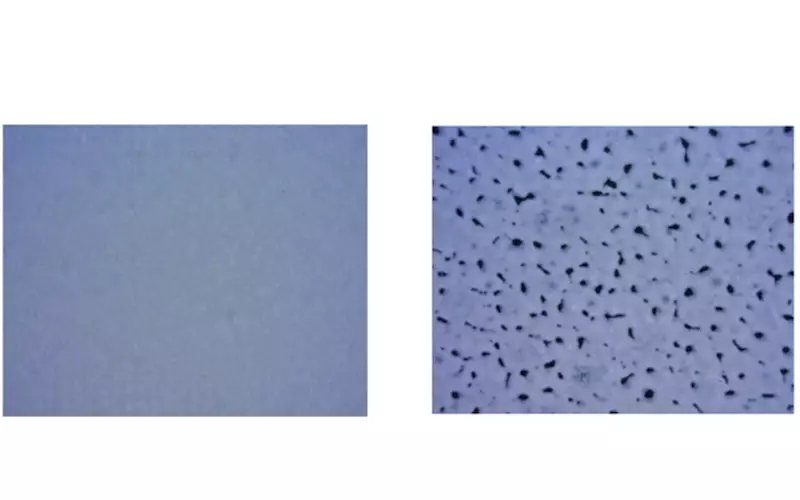

Image 1: Two samples, register the exact same opacity reading, 52 per cent, but the sample on the left offers a much smoother laydown, free of the pinholing and graininess evident in the sample on the right.

Encapsulate All Colours

Colour measurement started off as a unidimensional measurement until DuPont scientist Charles Reilly completed the foundational work that led to the multi-dimensional L*a*b* system, which accounted for colours as well as the amount of light associated with them.

This evolution was necessary because colour measurement needed to better mimic how the human brain, in conjunction with the eye, perceives colour. The reason is cones in the eye see the colour stimuli in terms of red, green and blue, but it is the brain that processes these stimuli along with the printed surface’s light characteristics to form a “perception” of colour. A similar multi-dimensional challenge now exists with measuring the brightness of white.

Opacity Isn’t Enough

For years, only opacity was used as the standard to evaluate white ink laydown in flexible packaging, but this method is incomplete. A substrate may have more ink and higher opacity, but if the ink does not lay down uniformly and shows pinholing or graininess, it still doesn’t provide a good white underlayer.

Image 1 shows a photograph of two samples that register the same opacity reading. However, the top sample has a much smoother laydown and doesn’t have the pinholing or graininess the sample on the bottom has.

To adequately describe the quality of the white ink laydown, we need to combine the measure for opacity, along with a numerical measurement for the uniformity of the ink laydown.

ISO 13660 standards for uniformity describe two measures that better relate the pinholing and graininess into numerical terms. They are mottle and graininess:

- Mottle can be defined by macro imperfections

- Graininess, on the other hand, is defined as micro imperfections, the small pinholes that can be seen when you look through a print sample

Consider these when the viewing area is broken down into squares and the standard deviation of the whiteness is measured. The mottle measurement breaks down the image into larger squares, so the resulting value represents variation in a larger square and can be viewed as a macro imperfection. On the other hand, the graininess measure breaks down the same image into smaller squares, so the resulting value represents variations in a smaller square and represents micro imperfections.

Brite Index

As seen in Image 1, a print sample can have high opacity, but if coupled with high graininess and high mottle, the visual impact can be inferior. Therefore, to evaluate the true “brightness” of white, you need to integrate the opacity value, along with a measure of imperfection. DuPont has created the Easy Brite Index that combines the opacity along with the uniformity measures (mottle, graininess). This single measure takes a three-dimensional concept and translates that into one number. The higher the index rating/measurement, the better the quality of the white.

How can printers get a higher index rating/measurement?

When ink is deposited onto a substrate, it does not always load well or disperse uniformly. Depending on various interactions of surface energy between the ink, the substrate and the printing plates used, you may get poor ink laydown that appears mottled. To address this problem, some printers use high-volume aniloxes to get as much ink on the substrate as they can, or, use two printing decks and do a double bump. Others use substrates that are already impregnated with the first coat of white ink. Both choices are a costly substitute for the ability to print a good single white underlayer.

To achieve the best white, screens have been designed to optimise ink laydown to get the best combination of opacity, low mottle and low graininess for solids. This is typically seen in high-volume printing when printing either a white undercoat or in solid areas using spot colors. Using solid screening technology delivers not only high opacity but lower mottle and graininess.

If better white coverage is achieved through more effective ink distribution, via screening, lower line count aniloxes can be used and less ink consumed. White ink accounts for most of the ink used for flexible packaging, both in terms of the cost of the ink and the amount of ink used.

Roller Effect

A simple analogy would be to imagine using a very thick nap roller to paint a dark room a lighter colour in your home. The roller’s thick nap will apply a lot of paint, but because it isn’t distributed well, the appearance will have an orange peel effect with lots of dark voids and light hills. Using a shorter nap or foam roller will deliver less paint, but because it is better distributed across the wall, it provides better coverage. This “roller effect” is similar to what solid screening can do for flexographic ink distribution onto substrates.

Solid screening allows printers to use smaller-volume anilox rolls for greater ink savings and offers the following benefits:

- Better overall consistency on large solid areas

- Improved opacity, reduced graininess and reduced mottle

- Higher print quality

- Elimination of trail edge void

- Faster print speeds

- Uniform ink layer

- Improved appearance of the final print

Flexibility of said screening is to be appreciated. It affords printers an opportunity to go to higher quality levels using their existing setup. More predictable, consistent output, under the same operating conditions, day-in and day-out, carries huge dividends — content customers and repeat orders.

See All

See All