Toluene ban in package printing: A look at alternatives

The Bureau of Indian Standards (BIS) has recommended a ban on toluene in food packaging printing applications in 2019 to improve the safety of food packaging. This ban will affect thousands of printers in India - from small print shops to large converters - as they will have to switch to new ink and solvent systems.

Oxea, a chemical company that has its origins in Germany, suggests that printers can economise on expensive printing ink and solvent by using an alternative solvent system called Propyls. This solvent system is said to achieve improved printing quality and be more economical according to results from its experience in South America and Europe

In light of the upcoming legislative changes in India, WhatPackaging? speaks to Oxea’s executive vice president global sales and marketing, Markus Hoschke, application expert, Dr Jens Klabunde, and global lead business development Propyls, Lucia Paniagua

06 Jun 2019 | By WhatPackaging? Team

Tell us about Oxea and why you created a product solution for the printing markets.

Markus Hoschke: Oxea is one of the world’s largest manufacturers of oxo chemicals. Due to the broad range of applications for our products, our application technicians constantly identify approaches for challenging situations such as the substitution of toluene in the printing process. Two of our products, n-propanol and n-propyl acetate and blends thereof, are promising alternatives to toluene or ethanol-based solvent systems.

We call it Propyls as a concept that is already an established industry standard in many regions of the world. Solvents such as ethyl acetate, ethanol, IPA, MEK, toluene, etc. have been dominating the printing industry in other world regions, but we have found that these are not the best solutions for printers. Oxea has decided to invest resources to promote the Propyls solvent technology globally and specifically to import technical expertise into India and offer this product as a solution.

How was the product received when you entered the markets?

Lucia Paniagua: People don’t like to change their habits, even if they know they are not economical. We mitigated the resistance by providing excellent technical and economic arguments from comparative trials from all over the world that showed the advantage of Propyls. We have been developing markets and supported many printers to switch from old technologies to n-propanol and n-propyl acetate.

In Brazil, for example, the cost and availability of ethanol was an entrance barrier for our products. But once we showed the market how they could save money and enhance their printing quality with this solvent replacement, the Brazilian market for Propyls increased from a few hundred tons to 16-kt in the first three years. Generally said, we noticed that Propyls are the solvent trend all over the world.

IBS has recently suggested a ban on toluene-based inks from a food safety point of view. Is that an opportunity for Oxea?

Dr Jens Klabunde: It is not a great opportunity for Oxea. The substitution of hazardous toluene with a safe and sustainable alternative such as Propyls is also a huge opportunity for the Indian printing market. With Oxea’s expertise and knowledge that we intend to share, the Indian printers could avoid the pitfalls of choosing the wrong solvent. Initially, ethyl acetate and ethanol replaced aromatics and ketones in the printing market due to their lower toxicity.

However, improvements in technology and increasing demand for better printing quality are forcing the industry to look for better solvent options. Propyls have been replacing conventional systems like NTNK (non-toluene non-ketone) inks and ethyl acetate in many world regions.

There are many advantages to the use of Propyls: They improve printability, re-solubility, brightness, image definition, and printing speed. They also reduce scrap, retained solvent, plugging, cleaning setup time, ink usage, solvent volume usage and VOCs (volatile organic compounds) from the solvent use reduction.

Lucia Paniagua: Our team will provide the Indian market with local supply and outstanding technical support

How do you view the issue in terms of environmental protection?

Lucia Paniagua: Environmental protection has become a high priority in India just now as we speak, and reduction is an important issue. A printer or packaging firm can easily save up to 20 per cent ink and 30 per cent solvents on an average only by exchanging conventional solvents or much more toxic toluene for Propyls. This means that 30 per cent fewer VOCs are released into the environment and that the material expense for ink can be reduced without any disadvantage. This measure immediately saves resources and supports India to make a big step forward in terms of food safety and protection of worker’s health.

Who are your existing clients in India? Which are the new segments you are hoping to cater to in India?

Markus Hoschke: Starting in 2016, Oxea has arranged test runs at some of the largest Indian packaging printers on an industrial scale. In these trials, significant saving potential, quality improvements, as well as other process-related advantages could be demonstrated to the companies. There were significantly less solvent residues in food packaging with Propyls compared to toluene-MEK solvent blends. As a result, many Indian key accounts have started to use Propyls as the main solvent in their printing procedures.

Dr Jens Klabunde: Oxea’s Propyls open the door for substantial ink savings at the better quality – a decisive advantage for the printer. Ink companies, however, are not interested in process optimisation, because their business model is based on volume sales. Unfortunately, that is a big hurdle for our market launch because printers typically rely on ink manufacturers’ recommendations for solvents, for example, ink. At this point, Oxea and its distributor can offer technical support and expertise.

Overview of the performance criteria of solvents used in package printing that distinguish Propyls from regularly applied thinners used in the print shop or by ink manufacturers

What are your plans for distribution in India?

Lucia Paniagua: We appointed one of the largest distributors of petrochemicals in India - Hazel Mercantile - as our main partner and local distributor. We have already trained their local Indian sales force and will further support them with Oxea’s technical expertise. Together with our business development and sales team, we will offer the Indian market local supply and outstanding technical support. Our Indian team is ready to work with the market and to share information about the benefits of Propyls.

What is the potential of the Indian market in the mid-term?

Markus Hoschke: Mid- to long-term is a very important potential market for Oxea in India. India is one of the fastest growing printing markets globally due to the rapid growth of local demand. Propyls have been a trend globally, and we expect the Indian market to adopt this solvent technology soon. Certainly, the decision of the BIS to restrict the use of toluene in printing for packaging materials used for food products is an excellent driver to make this replacement faster. Oxea, as a global leader in the production of n-propanol and n-propyl acetate, expects to be a strong supplier in the dynamic Indian market.

The Indian market cuts both ways: on the one hand, there is huge market growth coupled with the need to substitute hazardous toluene. This is a door opener to introduce Propyls on a broad basis. On the other hand, India is a large country, and it is not easy to judge how fast the toluene ban on food packaging will be implemented. In a mid- to long-term, we expect a leading role in terms of potential for our Propyls.

Why do you think this is an opportune time for you to enter the Indian market?

Lucia Paniagua: The timing is right. With our experience from the market introduction in Latin America and Europe, we see Oxea as best prepared to further grow the Indian printing market on a broader basis. Oxea’s business development team can assist printers in India, in a hands-on manner to share experiences and to shape the conversion processes for printers at minimum risk and effort.

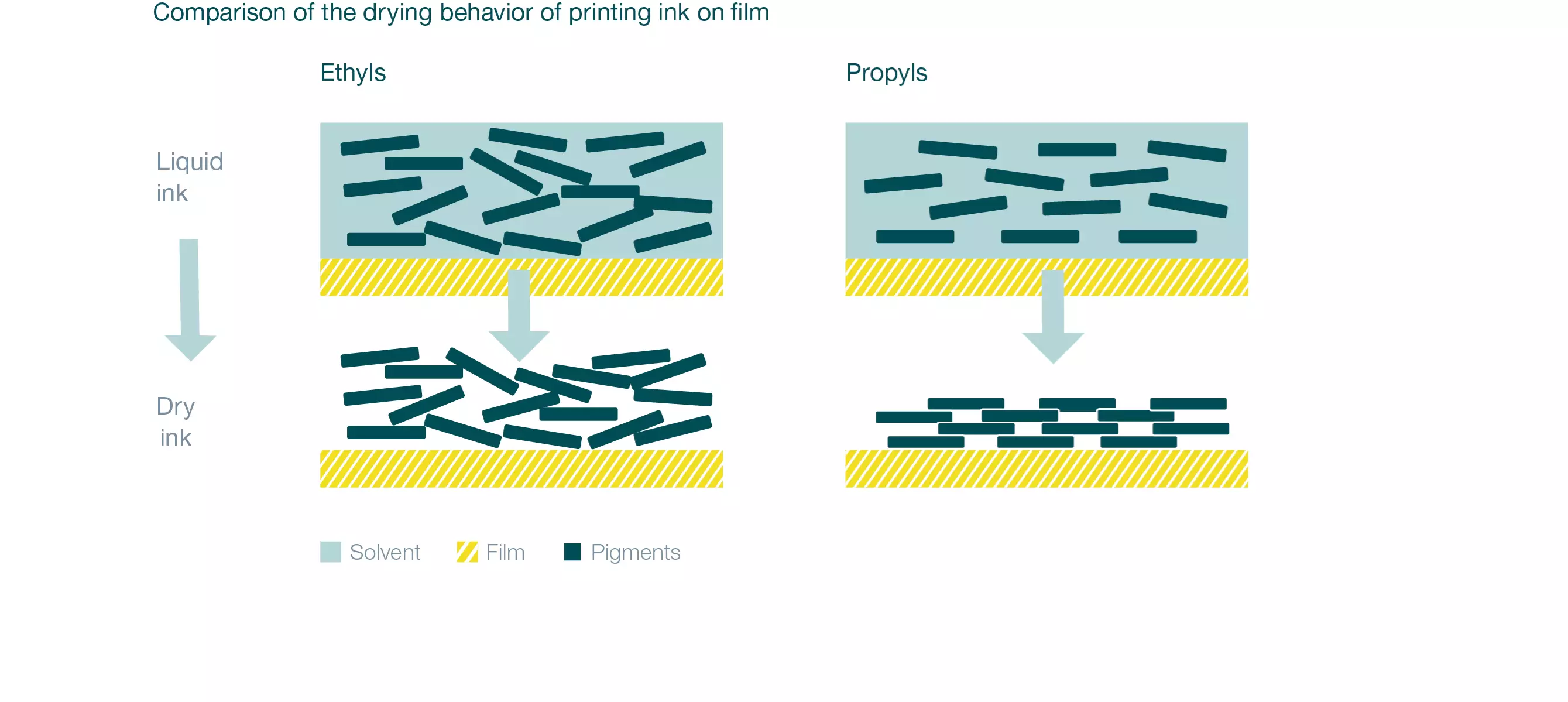

Explanation of ink savings in medium evaporating solvents like Propyls. Slightly delayed evaporation of Propyls results in better distribution of pigment particles while the ink dries

How will Oxea position its products in the Indian market, which is very price sensitive?

Dr Jens Klabunde: Our Propyls have superior properties, but we do not position them as a premium brand. We are fully aware that volumes used in print shop are so large that customers expect a benefit in terms of overall cost savings. Oxea’s price policy will carefully monitor this correlation, e.g., by optimising logistic and manufacturing scenarios for Propyls in order to be competitive with conventional solvents like ethyl acetate.

As in other price-sensitive regions, Oxea’s position will be to educate the market about the overall cost savings. Studies and customer trials have shown and confirmed that there are several advantages of using n-propanol/n-propyl acetate compared to other solvents currently used. The Propyls' benefits will be a key argument to overcome any potential obstacles on our way to enter the Indian market.

What distinguishes India to other regions in this context?

Markus Hoschke: India represents the most dynamic economy with hundreds of million citizens developing a middle-class way of life. They want to lead a healthy and sustainable lifestyle Propyls can contribute to this development if packaging companies are open to overcoming traditions like printing with toluene or conventional solvents.

See All

See All