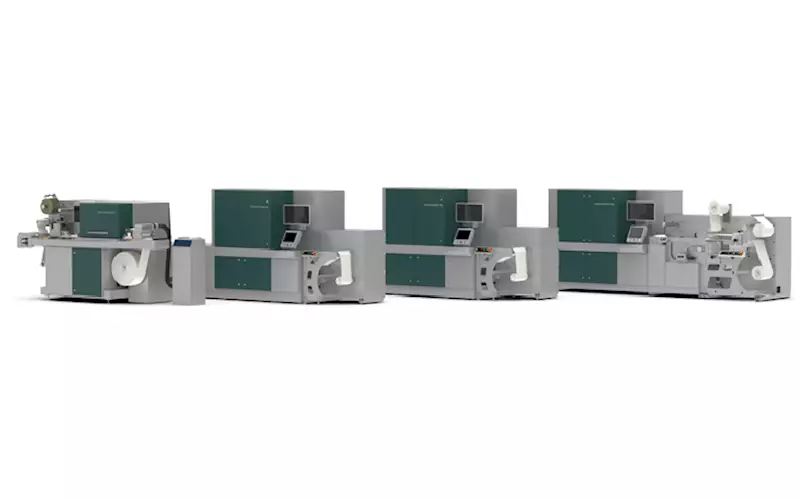

Product of the Month: Dantex PicoColour 210 digital printing press

Simon Cosh, digital business development manager for the Dantex Pico range, explains to Rahul Kumar how the Pico range offers efficient solutions with low cost of ownership to label printers

15 Apr 2021 | By PrintWeek Team

What does the machine do?

The PicoColour 210 is a high quality, but compact, industrial UV inkjet press, covering less than six sqm of floor space. The press prints and finishes labels from full raw reel to final finished label rolls ready to ship. It is a complete label production system, which includes full inline finishing. The optional extras include additional white, digital gloss varnish, variable data and lamination.

Which are the different models?

The standard PicoColour 210 is offered as a digital printing system with inline finishing, including rotary die-cutting. It can, however, be configured as a reel-to-reel press for use with an offline finishing system.

Is there anything in the machine which is available as a standalone, is the machine is modular?

The PicoColour is a complete label production system press. However, configurations can range from a reel-to-reel four- or five-colour press without finishing or with inline finishing, including, lamination, slitting, and variable data. The press is modular, so optional extras can be added in the field as a business changes or grows.

What was the thought process when the machine was conceived?

The PicoColour was conceived as an entry to mid-level complete label production system with a small footprint and no quality compromise. As the average label is 100-mm in width, the press prints two across at a highly competitive production rate. Finishing is standard. This reduces the need for extra equipment and reduces waste.

When was the machine launched?

The PicoColour was launched in 2016. Since then, various upgrades have been introduced including software, ink systems and several other items. PicoColour is, therefore, proven technology with high uptime, showing a fast return on investment.

What is the target market(s)?

As the PicoColour has been proven to print onto a wide variety of not just standard, but many ‘non-standard’ stocks; this enables the press to be utilised in a wide range of markets, including not only beverage, personal care, automotive and chemicals, but also fabric, tags and horticulture, among others.

What kind of substrates can it handle?

The PicoColour handles standard label stocks, with no primer required, coated and uncoated papers, PP, BOPP, wine stock and some unsupported films from 80 to 300 microns with added inter-colour pinning which helps ink adhesion onto even non-standard substrates. It also handles non-standard Tyvek, metallics, polyesters, and other synthetic substrates. Also, importantly, the material can be from 80- to 230-mm width and all sizes in between, which can help reduce costs further especially with expensive specialist stocks.

How fast is it?

The PicoColour can run at up to 35-m/min at a lower resolution. However, the standard speed is 25-m/min. The productivity is increased with the easy to use but powerful workflow, delivering high quality printready files to the press. The in-built finishing gives a faster turnaround, saves time, reduces waste and is more profitable.

What is the USP of the machine?

The PicoColour is a compact, high quality and very productive press. Inter-colour pinning, coupled with Dantex’s proprietary workflow and RIP solution, enables fast, consistent turnaround and exceptional colour control for consistent results for short, or even longer, runs time after time. The press is designed with in-line finishing for space and material waste savings.

How easy is it to use?

Very easy. Our customers have operators from a range of backgrounds operating their presses; from experienced flexo printers to novices who have never previously operated a printing press.

What training and support is on offer?

We offer extensive product training from pre-press workflow through to press operation, plus full training and global support. We have remote diagnostics which helps overcome the vast majority of issues.

Installation numbers worldwide? How many do you expect to install in 2021-2022?

We have installations throughout Europe, Africa and America and having proven the press technology and reliability, we are able to introduce this to new regions. We believe the PicoColour is an excellent fit for the Asian market. Despite the unprecedented Covid pandemic, we have had a very successful 2020 and expect to continue to increase our market share with further success in 2021.

Contact details

Amitabh Luthra,

managing director, Printers Supply Co

Email: amitabh@printersuppliers.com

Phone: +91-33-22379721 / 22379130 / 40064027

See All

See All