Made in India: Mahalaxmi RubTech’s Imprint range of offset printing blankets

Samir Parekh of Mahalaxmi Rubtech explains to Rahul Kumar how the company is bullish to capture more than 50% of the market in India

29 May 2019 | By Rahul Kumar

The Imprint range of offset printing blankets, manufactured by Mahalaxmi RubTech Limited (popularly known as MRT), includes Polset, Ultra, and Royal Green (for conventional printing); PrintUV (for UV printing); StripCoat (for coating and stripping); Royal Green and Spectra (for metal déco); Rapid-Web and Xpeedo-Web (for web printing); Robusto and Royal Green (for packaging); and spectra (Combi for UV and conventional).

According to Samir Parekh of MRT, offset printing blankets are essentially polymer composites manufactured by integrating three technologies namely rubber technology, textile technology and process technology. Parekh says. “To explain this in layman’s term, the offset rubber printing blankets are mounted on the rollers of an offset machine. This helps transfer ink on paper.”

Established in 1991, MRT started manufacturing textile printing blankets in 1992. In 1994, MRT started manufacturing rubber-coated fabrics for the defence sector.

In 2013, the company launched and started the commercial manufacturing of the Imprint range of offset printing blankets. “Last year, we launched two web/ newspaper blankets —Rapid-Web 1.70mm and Xpeedo-Web 1.96mm, marketed in India by TechNova Imaging System,” Parekh informs.

He claims that MRT is the only manufacturer of offset rubber printing blankets in India. The company also manufactures technical/ rubber-coated fabrics. He adds, “MRT is the only company in the world who manufactures offset printing blankets starting from base fabrics to complete blanket under one roof. More than 50% of our production is exported globally.”

The family-owned business has also expertise in home textiles, organic pigments, textile auxiliaries, specialty chemicals and weaving of apparel/ technical textiles.

The technology

“All our blankets are application-driven as required by the printers,” Parekh explains. “We have blankets for conventional printing, UV printing, packaging, metal décoration, publication and others. Each of our blankets is aimed at unique requirements of printing.”

He says apart from our blankets, the Indian market is catered by other global brands along with Chinese and low-grade blankets (popularly known as stock lot) taking a minuscule share, it’s important to offer quality and consistency in products.

“In terms of quality and consistency, our blankets offer at par or even better print results, easy and faster availability, and assurance of grade one quality with competitive prices. This effectively turns out to be a cost-effective solution for Indian customers who are often forced to buy grade two products with grade one prices,” he says.

Parekh adds that all the MRT blankets are designed and constructed to achieve longer mileages. “In fact, mileage or runability has never been an area of concern with our blankets,” he says.

The market

The blankets are marketed by TechNova Imaging Systems through its dealer network. Further, they cater to all sub-dealers and printers pan-India. “So, I can confidently say that our blankets are used by almost all good presses and printers of India,” he says.

Parekh says printers primarily look for consistent quality with consistent print results, along with easy availability of printing blankets.

He says there are some importers who import cheap and rejected (stock lot) blankets from China and other parts of the world and often push them to dealers and printers in India at a cheaper rate or at times at the higher prices of a fresh blankets

“Therefore, we regularly ask the industry people, ‘are you still importing printing blankets? Why? We are here, with made in India blankets. We are well-accepted in India and the global export markets for our quality, consistency and durability,” he adds.

Apart from the conventional printing blankets, the company also offers the premium blanket, Royal Green, designed and constructed for premium conventional printing but being used in other applications, such as metal printing, packaging and web printing. This, Parekh says, is an extraordinary achievement for the company.

He reiterates that the quality, consistency and durability of the company’s blankets are its USPs. “We have hardly found other available printing blankets in a similar capacity. If you are not using MRT Imprint range of blankets, you will have to either choose from imported blankets or low-quality stock lot sold at a higher price,” he says.

Quality and Consistency

Parekh says all MRT blankets are tried and tested products. “The entire range of our printing blankets is user-friendly and ready-to-use. We have in-house barring facilities for all type of barring. Thus, our blankets are fitted with bars and easily mounted on printing cylinders. Moreover, it’s easy to clean the ink deposition on the blanket,” he says.

When it comes to consumables, Parekh says, after-sales support is very important because these products are consumed daily and a small variation in quality can damage the entire printing press, repairing which will be an expensive proposition.

“We provide all kinds of sales and technical supports to our customers. We provide application support, and also send our technical experts and engineers as and when required by our customers.

Now, MRT is targeting to capture more than 50 to 60% market share in India, which Parekh says, the company is very closer to achieve the same. At the same time, it is planning to double its export figures this fiscal.

“This year, we will introduce few new blankets for packaging, stripping and coating, adhesive back and non-compressible blankets for tin printing/metal decor applications,” he concludes.

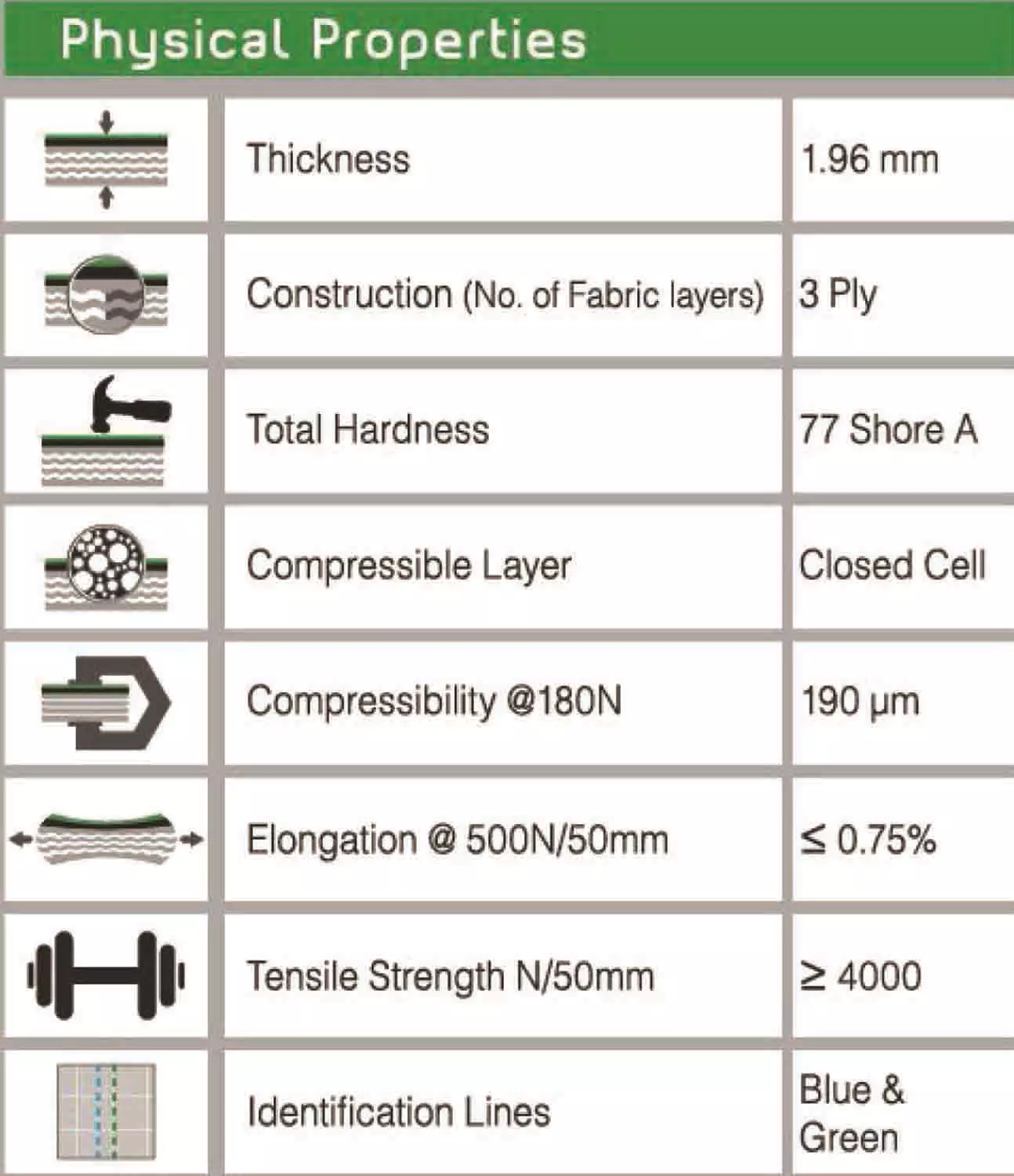

Specifications

Contact:

Samir Parekh, Tel: +91-9825108787

Email: samir@mrtglobal.com

See All

See All