Gallus EM 280

Himanshu Kapur of Mumbai-based J K Fine Prints says, the new EM 280 enables the company to produce difficult labels for sensitive markets

29 Oct 2014 | By PrintWeek India

Describe your company?

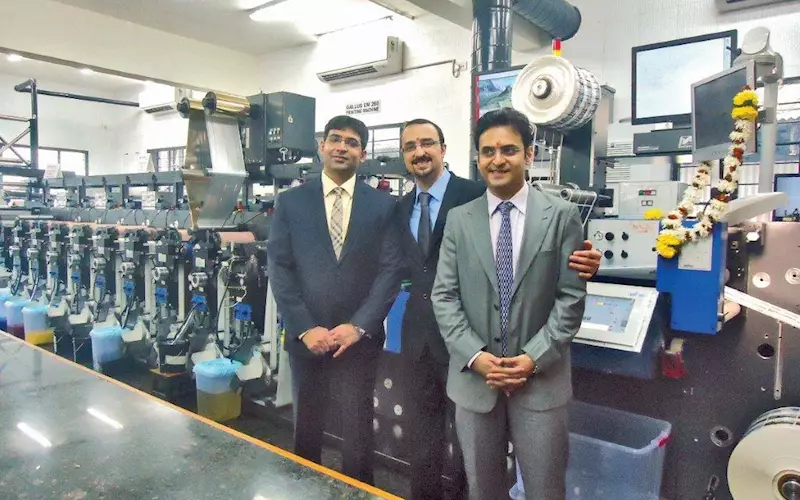

Established in 2007, J K Labels (J K Fine Prints) is a Mumbai-based self-adhesive label specialist.We began operations with the Gallus EM 280 and have recently invested in another EM 280, which is an advanced model of the earlier press. Besides Gallus, we also has seven-colour high-speed UV rotary label printing machines and four-colour label printing machines for small to medium run jobs. We cater to a diverse range of self-adhesive label markets such as automobile, food and beverage, cosmetics, pharmaceuticals, liquor, electronics etc. The company is managed by three co-directors – Himanshu Kapur, Rahul Kapur and Karan Kapur – wherein Himanshu looks after the technical side of the business while Rahul and Karan take care of marketing and accounts respectively.

|

Conclusion User’s verdict

Speed 4/5

Quality 5/5

Reliability 5/5

Value for money 5/5

Supplier’s Response

Samir Patkar, managing director, Gallus India, says, “The Gallus EM 280 has evolved over years since its launch in 1987. We have 75 installations of Gallus presses in India, of which over 60 are EM280. The first EM280 at J K Labels was installed in 2007 and since then J K has remained Gallus loyalist and this is evident from their recent installation of the second Gallus. The new investment shall allow J K Labels to print more efficiently by reducing wastage, thanks to the features like servo and auto registration. Thus the machine will increase their productivity with combination printing jobs using flexo, screen and inline foiling.”

Contact Gallus India

Samir Patkar

samir.patkar@gallus-group.com / 09820457878

|

|

How the Navi Mumbai firm bolsters operation with new equipment

The next generation of the family-run J K Fine Prints is enthused with the addition of the new Gallus EM 280 on its shopfloor. The new investment, which also included a slitting and defect detection and inspection system from ABG, is a part of the firm’s second phase of expansion. The consolidated investment, according to them, is that of Rs 30-crore.

The three co-directors of the Mumbai-based self-adhesive specialist, Himanshu Kapur, Rahul Kapur and Karan Kapur, are geared to increase their offerings to the label industry, in the FMCG, petrochemical, pharmaceutical, automobile and other segments in the domestic market.

“Our family has been in the label printing segment since 30 years. With the increasing consumer spend in an emerging market like India, one can say that the ever-competitive label industry in India is bound to grow more,” said Rahul.

Karan added, “While it has its challenges of raw materials and competitive pricing, the low per capita consumption of the self-adhesive labels in India hints at more potential and more growth.”

“The latest Gallus EM 280 installed is an upgradation to the homonymous predecessor. The new machine is fully loaded with advanced features that are not present in the previous EM 280. It is equipped with auto registration system, ink pumps, corona treaters, dual sensor system, web tension management etc. These features helps us to improve efficiency and eliminate human errors and thereby earn savings. The equipment also features a turner bar, which enables reverse printing,” said Himanshu.

A speed of 150m/min, ten colour units and braille printing are some of the other features loaded on the workhorse.

According to team Gallus and JK Fine Prints the machine is bound to expand the firm’s production capacity and clientele.

During the inauguration ceremony, Gallus Group owner and vice-chairman, Ruesch Ferdinand, said, “The demand for more sophisticated and efficient equipment has increased and so has the trend to upscale one’s operations being on the rise. The entrepreneurship spirit of the Kapur family coupled with their organisational skills ensures us the use of the equipment to its optimum capabilities.”

The firm began its operations with the Gallus EM 280 in the year 2007. Besides Gallus, the company also has seven-colour high speed UV rotary label printing machines and four-colour label printing machines for small to medium run jobs along with other converting machines. The firm also has high-speed slitting machines and numbering machines.

|

See All

See All