Univacco’s open house highlights foil application for label printers

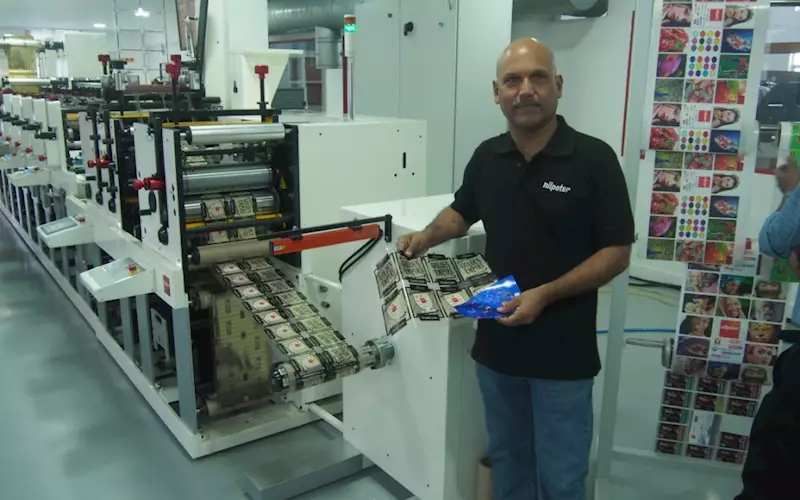

At the Univacco-led open house at Nilpeters’ demo centre, a host of label equipment manufacturers and suppliers teamed together to showcase capabilities on the narrow web presses.

05 Sep 2016 | By Sriraam Selvam

The half-day long event held on 2 September 2016 was convened by Dhana Impex, pan-India distributor of Taiwan-based Univacco products. This included live demonstration of two back to back foil application jobs on Nilpeter FB-Line press followed by brief presentations by the various partners at Hotel Green Park in Chennai.

Talking on the side lines of the demonstration Collin Thompson, product manager, marketing and sales, Univacco Technology said, “The motive of the event, besides highlighting the various foiling application with our products is primarily to show what solutions can be provided by all of us (suppliers) together for your business.”

“As a top cold foil supplier in the world we are committed to constant innovation with new formula and techniques which we think would benefit the Indian print industry too,” added Thompson.

Thompson highlighted the various foil products offered by Univacco specifically for self-adhesive, in-mould, shrink sleeves and double-sided gold labels.

The event was attended by nearly 50 customers from various parts of India.

“As partners of the event, we want to show the customers that they should look beyond the standard repro jobs and offer value additions in terms of decoration etc. Univacco and their proposition fit right in. We are running a double-sided gold label job and seemingly challenging in-mould label both with foil application and in-line die cutting today,” said Alan Barretto, managing director of Nilpeter India.

During his presentation Manish Kapoor, country head for sales at Nilpeter, shared some of the challenges and opportunities that is faced by label printers in India.

“If the label segment is growing at 15%, why am I not growing, is the questions that many ask, which I think is because we (label printers) are doing more and more for less and less,” said Kapoor.

“There are opportunities galore. The entry-level barrier has risen considerably, growth graph continues to see upward trends, customers realise the virtues of consistency and quality, and new markets are awaiting the arrival of innovative web converters,” he added.

Kapoor urged the audience to think out of box and insisting that there’s lot to learn from history before it is late.

“Apart from learning from history, the printers should start looking at new regional markets and also new sectors/products they can seize from other printing methodologies,” concluded Kapoor.

The open house was additionally partnered by Veepee Arts for prepress plate making, Kodak for the plates, Biesse for the tapes, Flint group for the inks, UPM Raflatac and Cosmo films for the material, Swedcut for the doctor blades and RotoMetrics for the die.

See All

See All