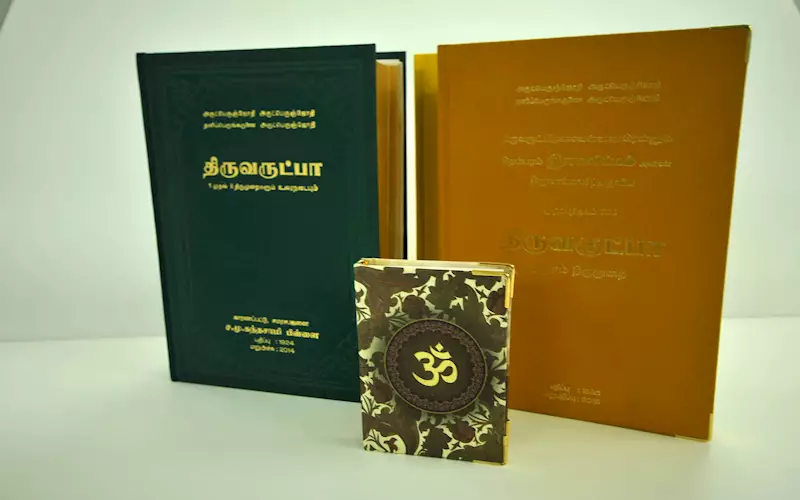

A rare book, Thiruvarutpa 1867 edition, torn and broken, was recreated once again, maintaining the book's originality by SFA Print.

The book, which was submitted as an entry for the PrintWeek India Awards, was produced by SFA for their customer Arutpa Pathippagam, Mettukuppam. The book, with an initial print run of 5000 copies, elicited a lot of praise from the jury panel.

The reason was simple. Consider this: the book was laminated on the front and the back. After it was structured pagewise to ensure the broken pages remain intact. Each page of the book was scanned individually and cleaned up to avoid the dust.

The pagination, pre-press and print, were all produced in-house. Hot foiling was perfected on the Sujatha foiling M/C and debossing. Ochsner's semi automatic machine was used for edge gliding. For hard-case binding, a Kolbus case-maker and hard cover line were deployed.

Finally, to protect the corners of the board, manual pneumatic machine gave it a fishing point. The cloth material was used on the cover with one colour and a four-colour was used for the inner sections. The 68 gsm natural shade of pharma paper and 120 gsm natural shade maplitho paper from ITC was used for the text and a 130 gsm of Hikote art paper was used for the cover.

A brief look at SFA

SFA is one of the top five book plants in Sivakasi. Located on a nine-acre plot with peacocks and the rarest of flora and fauna, the SFA Print unit is housed in a 37,000 sq/mtrs of built-up area. SFA has a team strength of 250, who work with a Heidelberg Suprasetter A105 and Heidelberg Speedmaster SM102P, Mitsubishi Diamond LS 1000, KBA Planeta V54, Komori LP37, Komori LP40 plus a raft of pre-press and finishing kit in their factory.

Founded in 2011, SFA is a sister company of Srinivas Group and deals with print production: labels to textile mills, fireworks and matchbox industry. Over the past five years, the group has transformed into a production unit which includes map printing plus stationery, with significant presence in pan India and UK.

Srinivas Viswanathan, managing director, SFA Print shares his experience.

He says, “Printing was our family business and it was started by Vivekanand (uncle) and his brothers in 1964. Earlier, the company was dealing in trade business but later it was re-modelled from a trading company to a printing press and observing the various aspects of the book making, it has been a learning experience for me. This was the early phase of SFA.”

“After completing my graduation, I started my career in print production. Later, I started to market the stationery products. Around that time, I moved to Bengaluru and started taking care of the Bengaluru commercial printing unit. During my training, I always followed a mantra of ‘Go ahead and keep trying’ and even today it’s been the same. SFA has fully supported my decision during my journey," he says.

He shares, “Being connected with print, we have been working in packaging and innovative stationery segment and will continue this for the future as well. We have also seen steady growth in consumerism, pharmaceutical, packaging and innovative stationery market. After the family crisis in the last few years, it was a challenging time for all of us and for the family as well. Due to which, we shifted to Sivakasi in 2011 and the collective support and experience has helped us to overcome the situation and stabilise the company in the market.”

According to Vishwanathan, “There has been a change in the mindset of the printers and a lot of printers are trying to fit in an old business strategy. However, from the age of block printing, we have seen the transformation in the printing industry from letterpress to offset printing. The 3D print is a much talked technology alongside with digital. The technology is advancing and it is moving at a rapid speed and it is important to move with the flow, but there are problems which still exist like infrastructural facilities and availability of labour. Plus, there is minimal support from the government.”

About MatrikaS

Branding and innovation are essential to be ahead in a competitive market. That's how, the brand MatrikaS was born. At MatrikaS, Vishwanathan says, "The clients are offered products such as notebooks, personalised journals, visitors’ book and registers, ring books and diaries. Every quarterly, we launch one new product in the market, with an innovative design."

He adds "In Sivakasi, the diaries and stationery items have been the centre of excellence, although the digital segment has significantly transformed with new technology and the applications are available in the market, and has been providing cost effective with customised solutions to the clients. In future, the offset and digital will not only co-exist but will also complement each other. Sivakasi has been providing job opportunities to umpteen numbers of people and we are sure that it will bounce back to its routine.

Viswanathan states, “In today’s commodity market, every business is competitive and the market shares are brunt and the cost is at higher front. We don’t compromise on the quality standards. Also few months ago, we had visited a plant and everyone at the plant spoke about the business model, which has top-down the net profits and their role to benefit the bottom line of an organisation because every individual has their own impact to its organisation. Every industry has more or less the same approach. The bottom line is nothing but the collective net income figure of an organisation. A company that is growing shall have its net earnings and it is said to be strengthening at the bottom line. All individuals at every stage of production play an important role for improvement.”

Going forward

Talking about the structure of the management Viswanathan, added that, "The directors and the board of directors are the decisions makers for the company. The organisation is divided into managers, analysts for marketing, finance and administration. Being a part of the print sector, I am passionate about the industry and I am committed to do my best for the industry and to my hometown."

Viswanathan concludes, “The youth are the driving force and they are the need for the industry. It’s our responsibility to encourage and tap the potential of each individual. During the courses, the students of the colleges should be taken for plant visits, training seminars y their management and workshops held by BMPA and Government Institute of Printing Technology (GIPT) for students has been a good initiative in Mumbai. On 28 May, 2015, we had a factory visit for students in Kanchipuram.”

According to Vishwanathan, “There has been a change in the mindset of the printers and a lot of printers are trying to fit in an old business strategy. However, from the age of block printing, we have seen the transformation in the printing industry from letterpress to offset printing. The 3D print is a much talked technology alongside with digital. The technology is advancing and it is moving at a rapid speed and it is important to move with the flow, but there are problems which still exist like infrastructural facilities and availability of labour. Plus, there is minimal support from the government.”

According to Vishwanathan, “There has been a change in the mindset of the printers and a lot of printers are trying to fit in an old business strategy. However, from the age of block printing, we have seen the transformation in the printing industry from letterpress to offset printing. The 3D print is a much talked technology alongside with digital. The technology is advancing and it is moving at a rapid speed and it is important to move with the flow, but there are problems which still exist like infrastructural facilities and availability of labour. Plus, there is minimal support from the government.”

See All

See All