Kudos, Optel’s India plant is now one year old. How have been the first 12 months?

Launching the Goa operations was an exciting journey. It is a part of Make in India campaign and embodies Optel Group’s mission to deliver affordable track and trace solutions with global quality standards so as to enable pharma companies in India to meet global compliance. The 42,000 sq/ft Goa factory was inaugurated on 30 November 2016. It was a challenging year in terms of acquiring necessary licenses, and building a world-class facility in line with our global standards, while recruiting and training a whole new team of 100 people.

How challenging?

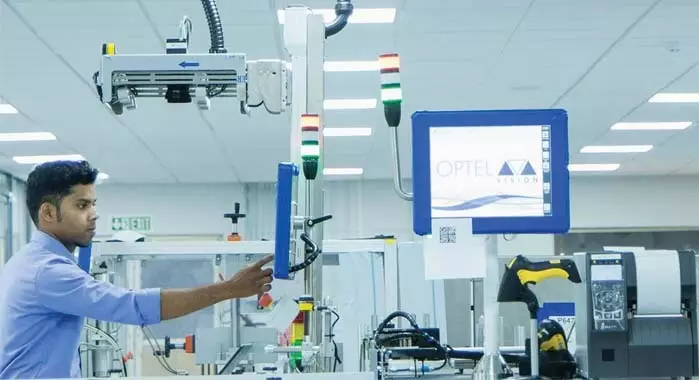

The biggest challenge was to scale up our engineering team capability in terms of skilled manpower, training needs, and align them with our culture and values. The serialisation and aggregation solution for pharmaceutical packaging lines in compliance with the global regulations is a very complex business. Every packaging line is different and so are most solutions created by us. We use a knowledge-driven business model. We have invested a significant amount of resources to create an in-house training centre at our Goa plant, equipped with real pharma packaging lines. We have spent significant time and energy to train our people by experts from Optel headquarters in Canada. Today, I am proud to say that we have reached our first goal and we are ready to spread our wings.

Shaunak Dave, CEO and MD of Optel India

Optel has been present in India since 2012. What prompted the setting up of a facility in India?

When our global leadership team saw this market as a critical one for the company’s long term expansion plans, the idea of setting up a plant in India was conceived. There are three reasons why India is a critical market for Optel. One, India is a global generics manufacturing hub as it contributes to 20% of the global production of generic drugs. Two, Indian medicines are exported to more than 180 countries which means a huge demand of global track and trace technology and compliance towards serialisation and aggregation regulations of many countries. Three, India has the highest number of US FDA approved plants after the United States. This was a key factor to expand our market in India, as our global customers wanted us to be here and supply our systems to their plants in India. After understanding the market dynamics and customer expectations, we realised the need of creating a sustainable base in India, where we could build affordable India/Asia specific solution so that our technology could reach the medium and small companies. Today, we have expanded our support in thirteen cities to support our customers in a better way. At our Goa facility, more than 80 passionate and highly qualified engineers are building customer-specific traceability solutions.

India has a large base of generic drug manufacturers. With deadlines nearing for EMVO (The European Medicines Verification Organisation) in Europe and DSCSA (The Drug Quality and Security Act) in the USA, how are Indian pharma companies gearing up to conform to these regulations?

The Indian pharma industry has been implementing serialisation and aggregation solutions for last seven years thanks to India’s DGFT (Directorate General of Foreign Trade)exports regulations. The industry, as well as the solution providers, have come a long way on this learning curve. The Indian market is very complex, and exports to more than 180 countries. The biggest challenge for this industry is to comply with multiple regulations from different countries for the same packaging line. The industry has realised that for regulated markets like the USA and Europe, not complying with the regulations in place means zero business, and if these regulations are not met properly with right solution and right partner, it may result in penalties, business loss and negative impact on their brand value.

How to maximise your track and trace investment?

The Indian pharmaceutical companies need to focus on two primary objectives while deploying a track and trace solution - To keep doing business by complying with the regulations

- While complying, ensure to have right technology deployed so that the line efficiency is not impacted, rejection and rework are limited and breakdowns are bare minimum.

After deploying the right technology, explore the additional benefits from these systems

Increasing packaging line efficiency with the line level data generated from such systems, we call it OEE and real-time monitoring system that helps us with preventive actions

Increasing supply chain efficiency (exception handling, effective return, rejection, post expiry returns management)

Supply chain visibility enhances flexibility and customisation

Effective product recall

Accessing direct customers through authentication

Significant cost reduction and increasing efficiency between CMOs and companies when they work on a profit-sharing model

Direct access to consumer

Use consumer data to generate more direct sales.

This seems like a gargantuan task. How does Optel help?

Optel works with customers as a solution partner and not as a product supplier. We invest a significant amount of resources to understand our customers’ businesses and long-term expansion plans, processes, packaging lines, equipment, packaging configurations, quality requirements, validation requirements and their operational, engineering and IT capabilities. After having assessed the customers’ wants and needs, our solution team builds a comprehensive assessment report and offers various options and solutions to address their comprehensive requirements. Together, we brainstorm and build a fully customised solution which can meet their present requirements without compromising line efficiency, while keeping everything scalable to meet future requirements. We have a centralised regulatory team which works with various regulatory agencies across the globe to understand their requirements and translate them into solution features, so our customers get “a complete solution” for global track and trace.

They say the implementation of track and trace systems is much more complex than it might appear. What makes it complex?

We have just begun the journey of adopting this new technology, which is highly complex in nature. Apparently, it looks like it’s just printing 2D barcodes and human readable characters. But this is just the tip of the iceberg. Besides diverse worldwide regulations and moving timelines, there are several other factors that make serialisation systems complex. These can be packaging and printing layout modification, packaging line modification and space constraint. Then you also have to consider line efficiency and overall equipment effectiveness, ERP, IT and warehouse integration, CMO integration and data exchange across the supply chain and government reporting.

What are the common mistakes Indian companies make in their approach to serialisation?

I would rather focus on cautions and future approaches the industry should consider. The main challenge is how to analyse ROI for global track and trace deployment and how to leverage the technology. As of now, almost 95% of implementations around the world are largely driven by regulatory compliance. When the companies think of compliance, ROI takes a back seat. However, we have seen many companies who started their own internal serialisation and authentication programmes, not for compliance, but for brand protection and fighting counterfeiting in the domestic market. It is estimated that 10% to 15% of world’s total medicines are counterfeit and this market is probably worth USD 75-200 billion. If a company has a mechanism to identify the counterfeit volume and deploy the right brand protection programme coupled with the right technology incorporating security features like covert/overt, tamper evident, serialisation, aggregation, and then, it’s return on investment (ROI) calculation can be very easy.

Five levels of serialisation

Level 1 Device level serialisation covers devices such as cameras and printers

Level 2 Line level serialisation adds the software that manages the systems on a packaging line

Level 3 Extrapolates the systems to site-level, with another layer of software to manage allocation of serial numbers, verification of data integrity and aggregation

Level 4 Corporate level serialisation which expands the capabilities still further, linking to the enterprise architecture thus integrating with ERP and IT systems

Level 5 Integration with global network. At the top level the serialisation capability can manage data transactions with other trading partners and regulators

Please elaborate.

What matters today is, if you do not comply with the regulations, your business will stop. If you comply with the help of an inferior or low-quality system and process, it will result in product recalls for issues like duplicate serial numbers or missing numbers or product mix-ups. Only one product recall will justify the ROI. However, the regulations have not been enforced yet or I may say not enforced in a proper manner. When the Indian regulations were implemented, many companies managed the deployment while investing as little as possible. Serialisation was and is not often perceived as a productive activity that has an added value. It is not linked to direct production value. But once the regulations are enforced, especially in a regulated market, I am sure, the scenario will be different. I would consider the following as a short-term, quick fix mindset: Just to deploy what is needed for now, keep the investments as low as possible even if it proves to be expensive in the long run with respect to OEE and other risks.

What’s the right approach, then?

Think beyond compliance. Find out how to leverage the technology to improve operations and supply chain efficiency, how to leverage this deployment for brand protection to stop your product from being counterfeit. This one is a prudent approach: How fast I can recover my investment by reaping benefits out of this “perceived dead investment.” Few companies have looked at what can be achieved beyond compliance.

CPHI P-Mec India 2017

Optel launched a new solution tamper evidence solution for EU FMD. The company showcased an integrated unit for carton serialisation and tamper-evident labelling unit, CLTracker TE. This is a compact, yet high-speed (more than 300 cartons per minute) system. It is ideal for customers who have space constraints and do not want to compromise on line efficiency.

Optel has recently acquired Verify Brand. How does this acquisition enhance your product portfolio?

With the recent acquisition Verify Brand, Optel can now offer a global end-to-end track and trace solution from Level 1 to Level 5. The addition of Verify Brand’s Level 4/5 serialisation capabilities and established data analytics expertise allows us to provide the connectivity pharma companies desire for complete track and trace projects.

Is serialisation alone sufficient to counter drug counterfeiting?

Here, I would like to quote a statement from FDA: “Because the capability of counterfeiters continues to evolve rapidly, there is no technology that can provide any long-term assurance of drug security. However, a combination of rapidly improving “track and trace solution” and product authentication technology should provide a better level of security for drug products in the years ahead.”

Indian pharma industry

The Indian pharma industry accounts for 20% of the global volume, but only 1.4% of value in the global market. By 2020, it is estimated to reach 55 billion USD in total, and one-third of the revenues will come from exports. "There are enormous opportunities for India to grow in domestic market, as well as internationally. I strongly believe that we all need to work together to establish a Made in India brand, with quality medicines at an affordable price on a global landscape," said Dave.

How successful has Optel been in India?

From 2012, we have helped many companies in India to implement serialisation and aggregation. Optel was the first company in India to implement a complete line with serialisation, aggregation and global IT integration for Level 4 and 5. Optel was the first company to implement an integrated system of carton serialisation and temper-evident labelling application for EU FMD (European Falsified Medicines Directive) requirements. Initially, it was difficult for our customers to accept our project management and stage-gate approach, but once the line was installed, validated and under commercial production, they realised the benefits of our reliable approach. No trial and error, no compromise on line efficiency, less rejections, user-friendly operation and minimum maintenance and downtime are a few benefits in addition to our 100% regulatory compliance.

But India is a price sensitive market...

India is considered a cost-sensitive market but what we have realised is that Indian customers are smart enough to purchase a product which offers “value for money” based on the total cost of ownership, even if the initial capital investment is high. I asked one of our customers about why they bought our solution even if it is expensive. He said and I quote, “One factor is compliance, the second is scalability, the third is ease in external/regulatory audits and the forth is efficiency (OEE). With Optel’s serialisation lines, we saved three days of production from line breakdown in a year and have reached our targeted ROI.” The rules have changed. With serialisation deployed on packaging line, if a serialisation system stops, the entire line stops and it results in huge production losses.

What are Optel’s plans for the next 24 months in India?

The Indian operation is expected to have a significant growth in the long run. In one year, our manpower has crossed 100 employees, and we are committed to continue our expansion. We have been striving to master the complex technologies, thus, the majority of our team members are young and aspiring engineers who take challenges to build innovative traceability solutions.

Factfile

Established 1989

President Louis Roy

Headquarters Quebec City, Canada

Employees 900

Manufacturing locations

Canada, Brazil, Ireland, and India

See All

See All