Figure 3 indicates the deficiencies of cyan, magenta, yellow colorants as ‘hue error’ and ‘grey error’. To understand this better the following explanation may help. Compare figures 1 and 2 with 3 and 4.

Yellow colorant absorbs blue light, magenta and yellow absorb green and blue, respectively.

Absorption of this one third of the spectrum makes the colorant appeared coloured it shows. If

the ideal colorant cyan is added with some quantity of ideal magenta and a little quantity of

ideal yellow then in this combination cyan colorant will absorb red, some quantity of magenta

will absorb green and a little quantity of yellow will absorb blue. The available cyan colorant

behaves exactly in this fashion as if it has contamination of magenta and yellow colorants.

If the ideal colorant magenta is added with some quantity of ideal yellow then in this

combination magenta colorant will absorb green and some quantity of yellow will absorb

blue. The available magenta colorant behaves exactly in this fashion as if it has contamination

of yellow colorants.

Yellow colorant is much better and very close to ideal yellow, hence deficiency can be disregarded.

In actual fact, each of the three inks is contaminated with the other two, but at this stage to

keep explanation understandable only major faults are highlighted. So when only available

cyan colorant is deposited on the white surface it is as if cyan, magenta, and yellow are

deposited as follows.

Available cyan = C m y

Similarly, for available magenta and yellow colorants

Available magenta = My

Available yellow = Y

But the matter is more complicated and is actually as follows.

Available magenta = Mcy

Available yellow = Ycm

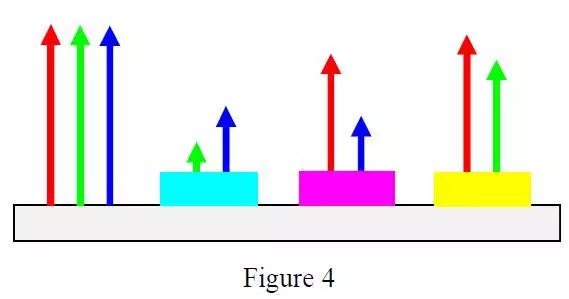

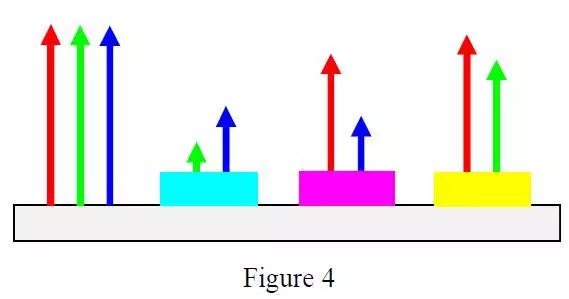

Due to these ink deficiencies when equal quantity of available cyan, magenta, yellow

colorants is mixed it works as follows.

cyan (Cmy) + magenta (My) + Y = CMmYyy

With equal quantities the combination has maximum percentage of yellow and a minimum

percentage of cyan. This excess of yellow and then magenta makes combination appear

reddish brown rather than grey. To convert this in to grey a higher quantity of cyan dye is

used in the paper print and transparency photographs and a bigger dot of cyan in the printing

processes compared to magenta and yellow.

The explanation above relates mostly to ‘hue error’ of colorants. The ‘grey error’ make

colours dirty to some extent and makes it difficult to obtain clean colours.

To calculate the deficiencies precisely and apply correction mathematical analysis using

measurement instruments is possible and has been used. See article 10. To successfully apply

the rule of four as mentioned in article 11 colour correction is applied in the process.

See All

See All