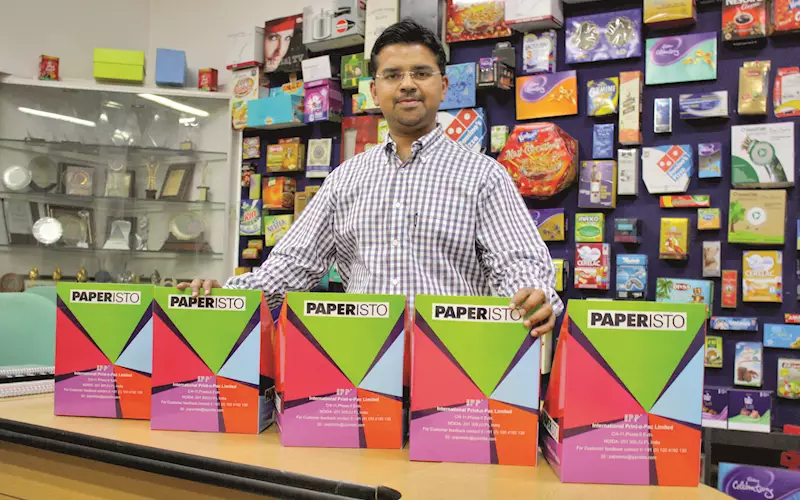

Rishabh Singhvi, executive director, International Print-o-Pac (IPP) talks to Rahul Kumar and shares his views on lifestyle stationery brand Paperisto and IPP's other expansion plans.

Rahul Kumar (RK): How did you decide to foray into stationery?

Rishabh Singhvi (RS): There were two reasons for entering the stationery segment. We think stationery complemented our book manufacturing capabilities and there are few organised brands in this space. IPP has long been a supplier of stationery to private labels internationally.

We soft-launched Paperisto for the domestic market two years ago. We test marketed our products in North India. It was not launched extensively as we did not have spare production capacity. We needed dedicated production capabilities. With our recent additions, we are now extensively retailing notebooks, note pads, diaries, multi-subject books, wiro-bound journals, children's coloring and activity books. In addition, we have recently launched an online platform, www.Paperisto.in for online sales.

RK: Do you feel encouraged by your growth thus far?

RS: The brand has grown 35% quarter-on-quarter for the last two quarters. We expect to double stationery sales this fiscal year. Furthermore, Paperisto is now the umbrella brand for IPP's B2C business. All our other divisions operate in the B2B space where we sell to other businesses. We are planning to add new products to the range. A few products will be launched in July-August in time for the school and university season.

RK: How large is the team, the setup and your reach?

RS: Paperisto has a dedicated team of 25 persons who reach 450 distribution points and over 50 wholesalers. We expect to grow geographically as well. Our focus is currently on the domestic market. We now have manufacturing dedicated to Paperisto. We have recently added German ruling and binding lines to grow our brand. Recently we have added to our marketing team. We now have dedicated sales persons for traditional channels and then also for modern trade, institutional and online sales.

RK: How do you design, develop and market a new stationery product?

RS: Once design development is completed, a defined market assessment procedure is adopted for test marketing and soft-launching a new product. The ground feedback is provided by the sales and distribution team. The validation process is stringent, well thought out and implemented carefully given the seasonality of various products and preferences across regions. Thereafter, dedicated production planning and operations teams take centre stage. Care is taken to ensure that the complete range of products is available in the sales channel at any time. The distribution network is continually replenished.

RK: How do you gauge the demand in the stationery segment?

RS: The scope is huge. Very few brands produce the quality that we do. Quality printing and finishing is an IPP trademark. We understand the product well. We feel that our quality will deliver results in the short-to-medium term. Attractive design and high quality manufacturing. That's our USP. Corporate sales are growing. So are sales at airports, rail stations and exhibitions. We are now selling at super markets, hyper markets and mall kiosks. We are targeting the educational hubs of Mohali, Roorkee, Kota and New Delhi NCR. There is clear strategy in place. We are encouraging all avenues with revenue generating potential. We are creating recall value for the brand.

RK: What are your expectations from the online platform?

RS: We expect the online platform to contribute 25% to revenues. Consumers can purchase online and also place bulk orders for shipping. It has also resulted in institutional interest. We are cross-selling. We are now manufacturing for many domestic private labels and are also looking at licensing options.

RK: And what are your plans for the core business – carton packaging and book printing?

RS: We are in the process of adding 1,50,000 square feet of shop-floor space. We have recently added 1,00,000 square feet of warehousing space to decongest existing operations. We are seeking growth in carton packaging and book printing in both domestic and export markets. We have grown well during 2012-13 and expect to generate similar growth this year.

We see scope for substantial growth within our current line of products. We are adding manufacturing capacity for both print and post-print. We have just added a sheet laminator and a new folder-gluer for packaging. Coming up next is a new perfect binder for book manufacturing and three new web presses. We have invested over Rs 100 crore in operations over the last three years. We now have over 1 million square feet of covered area in Noida and a significant land bank to aid future growth. We have capacities to convert 1,00,000 MT of paper and paperboard each year. This is a lot to focus on. We are also open to the idea of setting up alternative manufacturing within India or overseas and continue to seek suitable opportunities for organic and acquisition-led growth.

See All

See All