Star Product: EcoStitch All-Electric

The EcoStitch All-Electric hotmelt glueing system earns return on investment in as little as four months and can reduce glue consumption by up to 70%, says Ravi Kiran, director, Valco Melton

24 Oct 2018 | By Rushikesh Aravkar

What does it do?

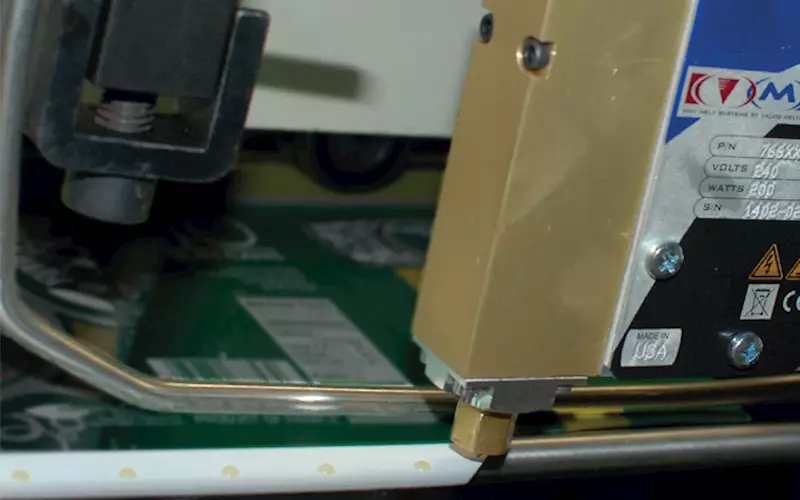

The EcoStitch is designed to help users reduce the adhesive usage by applying precision dots or using traditional beads. The unique EcoStitch feature can reduce adhesive usage and at the same time improve the bond quality. The challenge with standard hotmelt gun is that there are many moving parts. Ecostitch is an all-electric system, which means it has minimum moving parts. This enables it to dispense very small adhesive dots at a high speed. This product was launched two years ago in the USA. We have recently started selling it in the Indian market.

What are the benefits of all-electric system?

The use of an all-electric hotmelt system allows for the use of lower pressures and larger nozzles, therefore dispensing the same amount of adhesive through a larger nozzle. Therefore, fewer plugged nozzles.

The use of electric gear pumps and electric valves remove most of the seals and additional equipment required to run pneumatic pumps and valves. Each valve has a coil that operates the valve and one seal. Each gear pump revolves by utilising an electric motor, which eliminates the pump "wink" and the moving air cylinder that contains multiple seals and shifting devices. As a result, downtime is minimised.

Who is this machine aimed at?

This glueing system is useful for anyone who needs to dispense hotmelt adhesive. This includes FMCG companies; beverage companies; palletisation customers, and packaging users among others.

What are the challenges that this technology addresses?

The most frequent downtime on packaging lines involves changing failed pneumatic glue modules, plugged nozzles, and solenoids. Switching to electric guns eliminates the need for gun solenoids and modules that can be soiled and worn with a dirty, wet, and sometimes inconsistent air supply. By using electric guns, the lifespan of a valve module can be more than two billion cycles, depending on adhesive.

How does Valco Melton resolve these limitations?

Adhesive charring is not an issue with EcoStitch gun as it comes with an internal filter cartridge and flow-through design, which allows large particles or debris to easily clear the seating area inside the gun. The electric gear pump operates only when the parent machine is in operation and features a demand melt grid that can be customised by the customer depending on the application. By removing compressed air from the operational components of the hotmelt glue system, the variables that cause wear, maintenance and downtime that effect hotmelt glueing systems are eliminated.

What is the USP of this system?

There are several advantages. The MX electric valve is controlled by an EcoStitch driver that produces an intelligent dot and gap glue pattern that is configurable by the customer for their unique product requirements. This results in adhesive savings can be tailored between 10%-75%. Moreover, the valve life is in excess of two billion cycles depending on operating condition; almost 40 times that of a standard pneumatic valve. This results in increased production uptime. The user is able to eliminate nozzle plugging and associated maintenance by using lower pressure and larger orifice nozzle. Over and above all this, the users will be able to recover their investment in four months.

Tech specs

- Valve width-22 mm

- Valve height-155 mm

- Fluid pressure-70 bar

- Lifecycle-Two billion cycles

- Maximum cycle rate-15,000 cycles per min for short durations

How?

With fewer moving parts virtually eliminating the chances of failure, the spare parts stock is reduced to a minimum, resulting in lower investment, storage costs and downtime associated with the replacement of parts. On the other hand, the reduction in adhesive usage brings additional savings that guarantee payback in as little as four months.

How many machines have been installed?

We have recently started selling this system in the Indian market. PepsiCo is in line for installation.

See All

See All