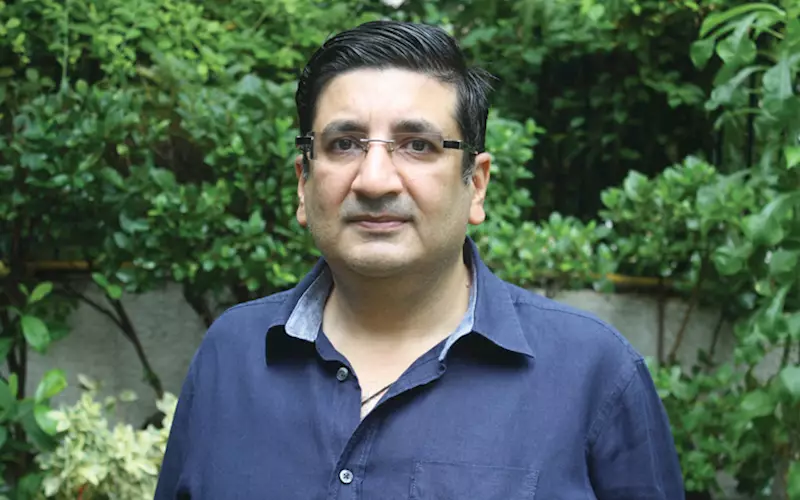

Setting a milestone in sustainability - Jatinder Shroff

Nutech Packagings with its commitment in reducing its ecological footprint has set up a unit at Greater Noida which is a certified green building from Indian Green Building Council (IGBC). Jatinder Shroff, director of Nutech Packagings in an interview with Rahul Kumar explains what it takes to construct a green building

28 Jan 2019 | By Rahul Kumar

Please explain how do the IGBC activities enable a market transformation in embracing green building concepts, materials and technologies?

Sustainability is a long term vision and requires an untiring commitment by an organisation. Nutech undertook this initiative by adopting building materials and technologies which consume less amount of energy and are not harmful to the environment as compared to constructing a conventional building.

In our endeavour, the Indian Green Building Council (IGBC) has been very supportive and has guided us through their recommendations and enabled us to achieve a green factory rating.

Which green features have you incorporated into your building?

We have used sustainable and passive design features, for instance, adequate daylighting. This feature includes using simulation modelling to achieve preferred lux level for efficiency as compared to a conventional building.

We have used competent materials like AAC blocks in the wall, double-glazed glasses, and low VOC paints, plus we have used thermal mass and insulations, such as high SRI paint and AAC wall with low u-value.

In addition, water saving is another feature. We have achieved it by using low-flow fixtures, efficient irrigation system and 100% rainwater harvesting along with recycling waste water through Sewage Treatment Plant (STP). We also monitor water and energy at various locations using an efficient metering system. We have also installed the Effluent Treatment Plant (ETP) as per requirement. Further, the plant is equipped with energy efficient equipment and appliances, such as an HVAC system with high COP, LED lighting (for interior and outdoor), CFC-free fire fighting systems, pumps and motors.

When was the idea born?

Nutech started with this endeavour in 2014.

How did you monitor the progress?

Nutech Packagings, in partnership with a green building consultant, conducted rigorous meetings and audits to ensure adherence with compliance set forth for green factory rating as per IGBC guidelines.

Three best practices that you follow?

First, the use of adequate daylight and ventilation in built spaces. Second, using water-saving plumbing fixtures and treating wastewater through STP and effluents by ETP. Third, use of energy efficient equipment and appliances as compared to the conventional building.

Three best practices that were most tough to follow?

Reduction of pollution level due to construction and monitoring of soil erosion, monitoring of the safety and well being of workers and conserving fertile top soil and storing it on site (so that latter can be used for landscaping).

In terms of tangible benefits, what should one be expecting in terms of reduction, for power usage effectiveness, and water consumption?

Using sunlight during daytime and LED can save an enormous amount of energy. Further, use of proficient plumbing fixtures along with waste water treatment plant helps in saving a lot of water and makes a building self-sufficient to a large extent.

How do you procure green-certified products and materials?

The IGBC provides a list of various green certified materials and vendor details. One can procure green building materials by contacting them.

How did you train your team?

Our green building consultant along with our project team played a vital role in educating our workforce by conducting various workshops on the use of eco-friendly material and safety.

Indian Green Building Council

The Indian Green Building Council (IGBC), part of the Confederation of Indian Industry (CII) was formed in 2001. The vision of the council is, ‘to enable a sustainable built environment for all and facilitate India to be one of the global leaders in the sustainable built environment by 2025.’

The council offers a wide array of services which include developing new green building rating programmes, certification services and green building training programmes. The council also organises Green Building Congress, its annual flagship event on green buildings.

The council is committee-based, member-driven and consensus-focused. All the stakeholders of the construction industry comprising of architects, developers, product manufacturers, corporate, government, academia and nodal agencies participate in the council activities through local chapters. The council also works closely with several state governments, central government, World Green Building Council, bilateral multi-lateral agencies in promoting green building concepts in the country.

Many Indian factories have water harvesting, solar panels and LED lighting and motion sensors in low-use areas. What more can they do in terms of design and health well being of the workers?

Incorporate passive design strategies such as the orientation of building, shape and size of building and designing according to the climatic zone of India. Then planning of spaces and designing it according to universal standards, for example, designing workspace for differently-abled as per norms. Lastly, providing indoor and outdoor breakout spaces for workers for relaxation, proving healthy food, water and ensuring safety along with organising regular health checkups for workers, and maintaining indoor air quality for better work efficiency.

What’s your renewable energy target for 2022 (75th year of India’s Independence)?

Substituting total energy consumption of the building with 20-25% of renewable energy is our top priority. We want to utilise heat extracted from various machines for corrugated boxes drying purpose and implement solar power-based lighting in external areas.

See All

See All