Reproflex3: Enabling the brands and converters a flexo win

Reproflex3 is all set for its entry into India. On the sidelines of the announcement, Andrew Hewitson, global managing director of Reproflex3 in a conversation with Priya Raju shares how its patented pending Project Blue flexo technology can be a game changer for brands and converters

08 Aug 2018 | By PrintWeek India

Globally pre-media companies are undergoing consolidation, and along the same lines, the landscape of pre-media in India is continually changing. Earlier one could list at least 30 influential players in pre-media, today there are hardly three to five players globally.

The pre-media players in India focus on offshoring which is a difficult market to sustain and there has been a shift in services to providing digital imaging, marketing communications, and print management services among others. Faster time to market holds the key.

Journey of innovation

The UK-headquartered Reproflex3 has been making its mark by innovating in flexography printing technology. Its journey began 22 years ago, with Andrew Hewitson and Trevor Lowes at the helm.

Hewitson says, “At Reproflex3, we are trying to create a new-age firm, which is focused on innovation concerning flexo printing. The firm has grown over the years due to the passion for high-quality print in flexo and delivering a marketers dream to deliver the intended quality output with flexo printing. We constantly look for new techniques, processes and one such example is Project Blue, among others.”

Converters from 15 countries are currently using Reproflex3 plates. The organisation integrates technological knowledge, subject expertise and execution capabilities into flexographic imaging for brands to enhance their packaging capabilities and efficiencies.

The firm has developed a unique graphics imaging process called Project Blue. “From its inception in 2015, its patent-pending Project Blue technology has delivered over 30 international awards to its partners,” shares Hewitson.

Project Blue

Project Blue is a combination of different screening technology, anilox technology and imaging technologies and challenges the entire process of flexo technology. It includes technical know-how and best practices in flexography printing with an aim to produce outstanding and vibrant, consistent prints.

It enables the brands to convert the print jobs with special process colour into a four-colour CMYK process to produce the same output. Hewitson says, “Project Blue is designed to maintain the brand’s packaging position as a primary selling mechanism, yet preserve efficiencies and integration with print partners.”

Speaking of the benefits of implementing Project Blue, Hewitson says, “Project Blue enables fixed colour palette printing, faster changeovers, short-run capabilities and improves efficiencies for printers and brands to achieve the best-in-class packaging, while still taking a cost-effective product to the market.”

To achieve the quality and tonal range, Reproflex3 works closely with its partner Sandon Global, a manufacturer of anilox roller. Hewitson says, “The result is an unprecedented image quality delivered by an ink transfer system capable of producing a near perfect tonal range at definition and detail over 300lpi.”

The Project Blue has touched around 1000 brands in the UK. “Sandon Global creates anilox roller with specific technology frequency to treat the surface which enables the right proportion of ink deposition, which results in a thin layer of ink deposition, reduced ink volume resulting in much finer halftone screen,” informs Hewitson.

Optimisation of print shopfloor

The implementation of the process includes training of the employees to understand the entire flexo printing process. Here factors such as maintenance and cleaning of the anilox roller are stressed on. “It is a challenge, and if you do not clean the anilox the ink can dry on the cells which affect the ink transfer,” explains Hewitson. All the small factors such as plate cleaning and storage, the mounting tape and how they are applied on the cylinders are accounted for.

“In conventional flexo, if you want to print a black barcode, you would need two separate plates, one anilox for heavy ink for barcode and other lighter one for the image. But we have a solution where this can be done with a single plate which will be 10% more expensive. But one has to understand that it will save one plate costs.”

“If a converter invests in Project Blue, then they will have to adapt to such infrastructure and work along with us. We deliver an entire eco-system and the required tools,” he explains.

Market shift

The UK and the European market has seen a change in the brand requirements and have migrated towards flexography from gravure. Hewitson attributes the shift to a brand’s changing requirements like multiple SKUs and packaging to suit the dynamic retail market. For example, the UK market has thousands of SKUs for various brands like Tesco, Walmart, Morrisons etc. Hence, the changeover time and production to execution time have reduced. Everything is competitive, and marketers are continually looking for an edge.

For Reproflex3, delivering high quality in a faster time to market in a controlled environment with the expertise garnered over the past 22 years has been its core strategy.

Venturing into the Indian market

Reproflex3 is increasing its geographical footprint and intends to become the largest Asian-Pacific flexo-imaging player by 2020. It is in the process of launching facilities in India, followed by Egypt, Africa, and Singapore. Reproflex3 currently has facilities in the UK, and the Dubai facility was started four years ago.

The facility in India, which according to Hewitson will be based in Mumbai and is expected to open in the third quarter of 2018. “We have been doing a market research in India for the past eighteen months and have been talking to the brand owners. There has been a lot of interest in adopting flexo as a print process among them,” he adds.

“The India market is geared up to take flexo as the preferred print medium. Today, with the volatility of products, there can be a regular long-run job of 1,000 tonnes, in addition to a promotional campaign with run-length of 10 tonnes,” quips Hewitson, “And this can be achieved by the flexo process, unlike gravure.”

Reproflex3 positions itself as the flexo champions with the complete know-how of the process. “We will play a crucial role in managing the translation from design to print and to know what exactly the marketers want and what can be delivered,” he says. “The key is to ensure that these two match and the print firm who is doing the job is equipped to produce exceptional quality.”

Hewitson says, “We felt unless we bridge the gap between the converters and marketers, this technology will not move forward. This impacted on our entry strategy with India. We have interacted with multiple brand owners in the country and they are asking us to create a flexo ecosystem and not push a product and we are happy to do so.”

Reproflex 3 plans to bring in the entire knowledge of flexography and will ensure the entire knowledge transfer is done for the converters. “We will get our trained personnel’s from the developed markets and would train them and deploy them at the shopfloor of converters who will be our partners and teach them how to push a CI flexo machine to get exceptional results with implementing best practices.”

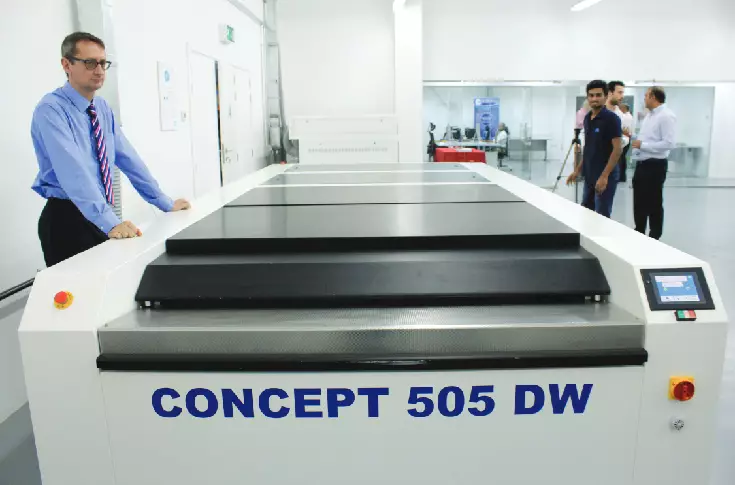

Reproflex3 plans to open a unit in Mumbai by the third quarter of 2018

The road ahead

Reproflex3 will establish a set-up in Mumbai as a flexo experience and educational centre where brand owners and print converters can come and understand the flexo process. The centre will also have a plate making facility and colour management system. The firms plan to rope in the multiple stakeholders like ink manufacturers and anilox manufacturer so that the brand owners can have a complete experience of flexo technology.

He says, “It will be a facility with the best technology and product, and we are looking to replicate our facility in Dubai and Newcastle. India being a large country, we plan for a bigger set-up, and it will be a continuous investment. We will also explore the possibility of a strategic partnership with existing flexo imaging players and flexo printers with in-house capabilities”

“The plan is to enable converters to deliver an efficient product while saving costs,” informs Hewitson.

See All

See All