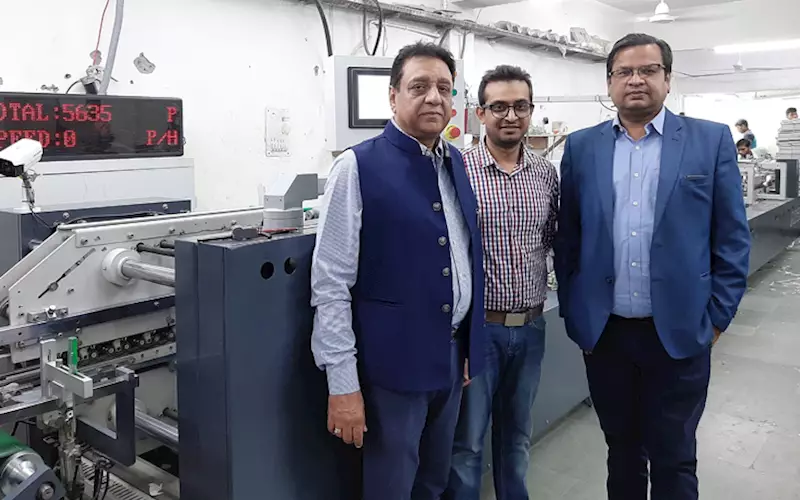

Delhi’s Bhai Printers opts for DGM SmartFold 800PC

New Delhi-based Bhai Printers has installed a folding-gluing machine from DGM. The installed folder-gluer can run a straight line, crash-lock bottom, CD cover/ pocket cover of solid board up to 800-gsm and 3-ply cartons up to 20-mm folded thickness.

09 Dec 2019 | By Rahul Kumar

The machine is running at the company shopfloor since September and according to Rajiv Khurana of Bhai Printers, the company’s production has increased up to 50% since the installation.

Rajeev Khurana of Bhai Printers said, “We opted for DGM as it fitted our requirement, pocket and expectations. Plus, its technical specifications are equivalent to top models of other available popular expensive machines. It is well affordable compared to its closest option in the market. Though it is a Chinese machine but with rich experience and no doubt quality is at par.”

Khurana said since the installation, the company’s production has increased manifold. “Prior to the DGM, we used to manufacture more than one lakh side-pasting boxes but after the DGM, we produce averagely more than eight lakh boxes in a 12-hour shift. Earlier, most of our operations were manual, but now we have shifted the entire operation to automatic mode.”

He said the installation has not just increased its productivity and efficiency it has also helped the neighbouring printers. As Bhai Printers is the only packaging converter in the vicinity with such a strong finishing line, the neighbourhood printers are using the spare capacity of the machine to complete their jobs.

Bhai Printers is Rajeev Khurana’s second foray in the printing industry. He entered the industry in 1983, but shut hope in 2005, before re-established the plant in 2014 on the suggestion of his son Ketan Khurana.

Bhai Printers is a 100% pharma focused printing facility and exports 15% of its total production.

The company’s post-press is equipped with one India-made folding gluing machine, two manual die-cutting machines, one automatic pre-owned die-cutting machine from Bobst and the recently added DGM folder-gluer.

“Our production facilities are fragmented. Our main production facility consists area of more than 8,000-sqft, another 3,000-sqft is equipped with Heidelberg four colour SM 72. We are planning a new print production facility and that will be equipped with a five-colour with online coating 28x40-inches printing press and DGM die-cutter and folder gluer in Okhla Industrial Area. The plant will be functional by March 2020,” Khurana said

The company converts around 60 to 70-tonnes of board per month. “We were growing at 10% per annum, but since the installation of the DGM, we are growing at 40%,” Khurana added.

DGM India has installed more than 20 machines this year. More than 50 DGM machines have been expected to be installed in India by the end of 2019.

See All

See All