A technical knowhow on mineral oils in food

Siegwerk India's Jatin Takkar highlights the health risks caused by mineral oils found in food products

10 Apr 2021 | By WhatPackaging? Team

An analytical investigation carried out in 1989 by the Food Control Authority in Zurich, Switzerland first discovered that mineral oils can be found in foodstuff. Since then, mineral oils have drawn a lot of attention from the media as well as consumers in the last decade.

In 2013 and 2015, the German magazine Ökotest analysed oat flakes and found mineral oil hydrocarbons (MOH) in 75% of the tested samples. In 2015, the NGO foodwatch analysed mineral oil saturated hydrocarbons (MOSH) and mineral oil alkylated aromatic hydrocarbons (MOAH) concentrations in 120 dry foods. Their packages were detected with MOSH and MOAH in 83% and 43% samples respectively.

In 2016, the Danish Consumer Council Think Chemicals measured MOH’s in 16 samples of cardboard and food packaging. And among those samples, seven exceeded MOSH and MOAH concentration of 24-ppm and 6-ppm respectively.

In 2017, Dutch cheese biscuits were recalled from the market due to the presence of up to 190-mg MOAH per kg. The MOSH concentrations in the food product further exceeded 1,000 mg per kg.

So, why were these food products recalled from the market? The problem is their harmful effect on human health. Some MOSH can accumulate in the organism and some MOAH are potential genotoxic carcinogens. And one of the main causes for MOH in food packaging is the usage of recycled paper or cardboard. Once used in packaging it either can contaminate the foodstuff via diffusion or by gas phase migration.

Definition of MOH

MOH are not a chemically well-defined substance, but a highly complex composition of various hydrocarbons. They are mainly derived from crude oil but equivalent products can be synthesised from coal, natural gas or biomass. The EFSA considered in their “Scientific Opinion on MOH in Food” hydrocarbons containing 10 to about 50 carbon atoms.

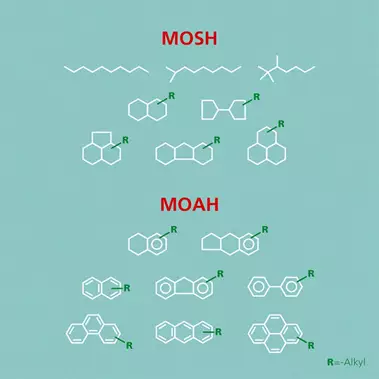

The acronyms “MOSH” and “MOAH” have been introduced by Biedermann and Grob in 2009 to distinguish these substances among others from the hydrocarbons of plant origin (relating to MOSH) or the polycyclic aromatic hydrocarbons (PAH), which consist of a limited number of largely nonalkylated ring systems.

MOSH comprise open-chain, often branched hydrocarbons (commonly: paraffin) and cyclic, saturated hydrocarbons, mostly alkyl-substituted (commonly: naphthenes); while MOAH mainly consists of highly alkylated mono- and/or poly-aromatic rings.

Sources of mineral oils

The contamination of food with MOHs can have two main reasons. Either the foodstuff is contaminated during the production process or the packaging could have caused the contamination.

There are a varied number of reasons for food contamination during production and processing. For instance, lubricating oils from machines can contaminate the harvest or jute/sisal bags can be contaminated with mineral oils. Furthermore, the EFSA indicated contamination by the use of release agents in bakery products or pesticides.

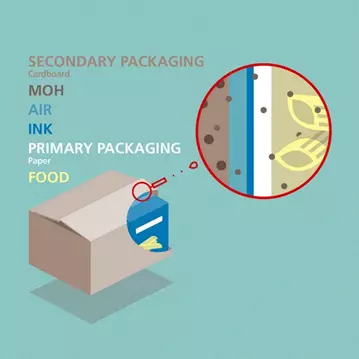

The contamination of foodstuff by packaging is mostly caused by the usage of recycled paper or cardboard, which can have high amounts of MOHs, mainly originating from mineral-oil-based, non-food grade newspaper inks. The strongest contamination will take place if the primary food packaging itself is made of recycled paper. Other sources could be, for example, directly on the packaging printed MOH containing inks or the use of corresponding adhesives/Hot melts.

The transport box could also be made of recycled cardboard and the mineral oils contaminate the food by migrating through the primary packaging into the food. This corresponds to a combination of gas phase – and diffusion migration.

Health risks

The toxicology of MOH depends very much on its mixture and the substances involved.

The most critical fraction is represented by PAH with three to seven rings and no or little alkylation. These substances are genotoxic carcinogens, whereas some highly alkylated MOAH can act as tumour promoters but are not carcinogens themselves. Nevertheless, MOAH can accumulate in the human body and therefore the German BfR recommends, that migration of MOAH into food should not be detectable.

In humans exposed to MOSH, microgranulomas have been observed in different organs for substances with a range between C16-C35, whereas no adverse effect was observed for MOSH between C10-C13. Even if these microgranulomas are considered of lower toxicological concern, the German BfR recommends, in this case, the minimisation of the migration of MOSH into food according to the As Low As Reasonable Achievable (ALARA) principle.

Siegwerk’s food packaging inks - A solution

The best option to prevent food contamination with mineral oils via inks is the use of packaging inks that simply do not contain any MOH’s. In the manufacture of all inks and varnishes supplied by Siegwerk that are intended for food packaging, mineral oils are not used as intentionally added ingredients.

In our comprehensive raw material introduction process, we request from our suppliers the disclosure of even minute amounts of mineral oils (MOSH and MOAH, in the range of C10-C35). This knowledge enables us to formulate our inks responsibly – without mineral oils. In very few cases, unavoidable traces of mineral oils may be part of important raw material.

Jatin Takkar is the manager – product safety and regulatory at Siegwerk India. He is a food technologist and has worked with various MNC’s like Nestle and Kraft Heinz before settling in at Siegwerk India.

Jatin Takkar is the manager – product safety and regulatory at Siegwerk India. He is a food technologist and has worked with various MNC’s like Nestle and Kraft Heinz before settling in at Siegwerk India.

At Siegwerk, Takkar is responsible for the product safety and regulatory segment and ensures the formulation of compliant inks which are demonstrated by systems and supported by documentation.

See All

See All