Xeikon adds two new entry-level presses to its label printing portfolio

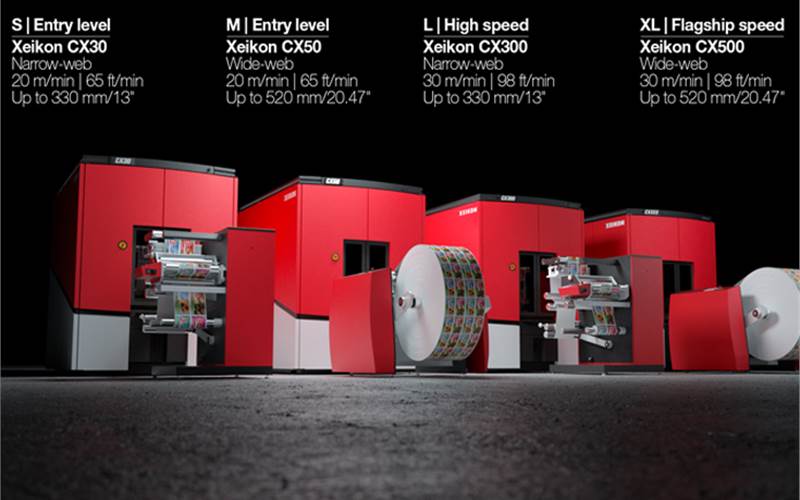

Xeikon has announced the addition of two new digital label presses — the Xeikon CX30 and Xeikon CX50. Building on its sixth generation platform and based on Cheetah 2.0 technology with new generation interfaces and cloud connection, these new presses are designed to offer maximum OEE. The Xeikon CX30 and Xeikon CX50 fit perfectly in the Xeikon portfolio between the Xeikon 3030 REX and Xeikon 3050 REX entry-level presses and the higher-end Xeikon CX300 and Xeikon CX500.

18 Mar 2021 | By Rahul Kumar

Xeikon has designed and developed the two new presses to suit any label printer operating on ‘middle capacity’, that is, 20,000 to 40,000-sqm or 30,000 to 55,000 MSI in all end-use segments but excelling in the pharmaceutical, food, and wine and spirit label sectors. The new machines are available for physical and online demonstrations at Xeikon’s Global Innovation Center in Antwerp, Belgium, and globally commercially available as of Q1 2021.

Filip Weymans, VP, marketing at Xeikon, said, “Part of the Xeikon strategy going forward is to make sure every label printer and converter has the maximum choice to purchase a Xeikon press which can help them drive business growth. A successful and cost-effective investment in a digital production solution works best when it is based on expected, realistic print volumes. Xeikon’s Cheetah 2.0 series offers competitive running costs, and printers have the opportunity to successfully expand the capabilities of their press (by upgrading either in speed or width, or both). The Xeikon CX30 and Xeikon CX50 are an appropriate choice for printers and converters looking at digital for the first time with future plans to expand and grow their operation — also for online label printers who are seeing their business explode.”

Both the Xeikon CX30 and Xeikon CX50 are ‘middle capacity’ presses that can be upgraded on site

Cheetah 2.0 technology is based on Xeikon’s scalable press architecture that includes five print stations and a full rotary process with a variable repeat length. Each station utilises Xeikon’s dry toner process and a variety of print widths up to 20.3-inches using an LED imaging head operating at 1200×3600-dpi and delivering offset/gravure image quality.

The Xeikon CX30 and Xeikon CX50 are both driven by Xeikon’s powerful and intelligent X-800 digital front end for ultimate efficiency and full automation.

“With Xeikon’s long standing expertise, we have developed the deeper understanding that can help label printers and converters with all aspects of running a successful digital business, from choice of equipment (10 label presses) and choice of technology (dry toner and UV inkjet) to workflow integration and expert colour management services. We are recognised as a go-to trusted advisor and solutions provider. Xeikon wants to help the label printer and converter transform his label manufacturing into a digital label manufacturing — not just digitising the printing aspect but also the other aspects of the manufacturing processes inspired by digital printing,” Weymans concluded.

See All

See All