Virtual.Drupa 2021: Seismotion innovates double-fold non-glue steel bar for blankets

Poland-based Seismotion produces a wide range of steel and aluminium bars, which the company is showcasing at the Virtual.Drupa 2021.

23 Apr 2021 | By PrintWeek Team

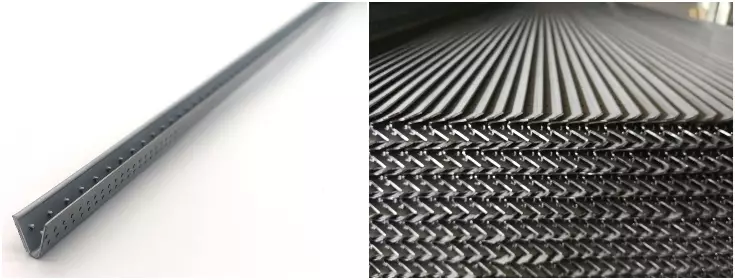

“Our latest invention is the NPP bar, which is 15x15x13-mm. That is a double-fold non-glue steel bar with perforation on both sides. What makes it unique is the two-side perforation. That means the bar fits to every kind of the blanket regardless of its layer structure and the grip is strong enough to have better results than industry standards,” Nikos Drosakis, executive managing director, Seismotion, said.

Drosakis explained: “I think non-glue steel bars make a big difference. If we consider that standard barring of blanket using glue, depending on method, needs time from five to 24 hours to get the full bar grip strength. This includes all additional operations like preparing the glue, gluing the blanket, curing the glue in the oven, and so on. Now, what we need to do is just to crimp the bar on the blanket and it's ready to go. Of course, not every bar can be replaced by a steel non-glue version. However, those which can make a big difference, especially when in the pandemic days, we often suffer from lack of personnel. By reducing the time of the barring process, we can try to minimise the impact on the company production rate as one person can make more blankets.”

Drosakis said for the industry, 2021 looks better than in 2020. “Now, the market is slowly picking up. Probably, it is because we have learned how to live and function in a new environment. The formula of how Drupa is being held this year is a perfect example. We have recovered from the first shock and now, we are working hard to bring the printing sector back to normal,” he said.

On the subject of the pandemic driving eCommerce, Drosakis said, a lot of companies have moved to the internet and advertising has become 100% electronic. For the common person, it means less leaflets, brochures, catalogues to be printed. “I believe, for printers this process already started years ago, but it has been compensated by constant growth of the packaging market which will continue for many years at a level of 4% per year. Don’t forget that pandemic stimulated the demand for cardboard boxes. I think that eco-packaging, if not already, will be the new area for printers. It is only about the ability to adopt, nothing new in a constantly changing market. Offset in that case should be safe, and we will be helping our customers to keep it that way,” he added.

He said, the company is working closely with its customers and is being responsive to their needs. “Even though we have more than 20 years of experience in this business, we always listen to the converters what they need, and we are here to help them. A good example would be designing a new master-bar for Mailander press. One of our clients wanted to use the latest NPP bar for their blankets. However, to fit this on the Mailander machine, he also needed a different master-bar. As a result, we came up with a new design that fits a steel bar. That product brought benefits to converters as the barring process is a lot shorter, and also to the printing company because this design made the blanket easier to install,” he added.

See All

See All