The making of Holostik’s UV embossed film

Established in 1991, Holostik is a pioneer and leader of anti-counterfeiting, labels, packaging and supply chain solutions in India. With goodwill of around 30 years, the company has become one of the largest manufacturers of security OVDs (optically variable devices) in the world in terms of volume.

17 Apr 2021 | By Rahul Kumar

It is not only one of the best global manufacturers of these products using the best global technologies, but also a CMMI- Level 3 certified developer of supply chain software. With the responsibility of solving the customers’ counterfeiting issues, the company believes in providing a complete ‘phygital’(physical+digital) solution.

Also, with a clear belief in innovation and technology the company spends about 5% of its annual budget on such R&D and technologies. Holostik has catered to more than 10,000 clients in 90+ countries around the world. Some of the prestigious clients in its portfolio include renowned names like Unilever, Coca-Cola, ITC, Konica Minolta, Dupont, Timex, Hero, Johnson & Johnson, Bridgestone, Diageo, Novartis, Abbott, and many others. As a testimony to its excellence, the company has received certifications like ISO, Drug Master File, Agmark, HSSMS and many others.

Standing firmly on the pillars of innovation, technology, values, and sustainability the company has successfully secured businesses, supply chains and consumers worldwide, which is true to its mission of ‘Authenticating supply chains, securing lives’.

UV embossed films

Among a wide range of Holostik’s products and solutions, UV embossed films have garnered massive demand and popularity due to their supreme aesthetic and strong visual appeal which makes the client’s product highly saleable. UV embossed films are mainly polyester films coated with UV curable resin, which are later cured by high power UV light at the time of embossing. UV embossing technology helps to produce higher quality lens/3D effects compared to hard and soft embossing processes.

UV embossing is a roll-to-roll manufacturing process consisting of 4 steps:

The coating process: A flexible substrate film such as polyester is unwound from a reel and then a liquid UV curable resin is coated on the bottom side of the film. The film is dried to remove the solvent from the resin.

Curing process: When the film is being embossed a high source UV light cures the resin.

Rewound: In this stage the completely cured embossed film is rewound on the reel.

Metallising: In this process, the UV layer is sandwiched between the metallising and film layers to form the final product.

The UV embossed film provides strong brand appeal to the product and makes it look unique on the shelf. The film is highly durable and thus, the effects on it remain unchanged until the end of product’s life span. It can include wide variety of effects like CRI (crystal relief image), PRI (platinum relief image), lens etc which gives it a distinct look. In addition, the film also includes anti-counterfeiting features embedded in the customised artwork.

The UV embossed film comes with thickness of 12- and 23-microns PET for carton and 50- and 36-micron PET for labels. UV coating comes from 3- to 7-gsm and available as metallised/ transparent. The film can incorporate any customised effects and more than 20 generic effects, texture, lens, images, and pillar of light.

Applications

The UV embossed films can be used to make 3D UV embossed labels and 3D UV embossed folding cartons. While UV embossed labels can be made with or without laminating the film with paper, UV embossed cartons are made by laminating the film with paper board.

The UV embossed films and its applications have changed the world of packaging forever. The films have become popular among FMCG, pharma, nutraceutical, personal care, and many other industries. This is due to the incorporation of various aesthetic and visually appealing effects and designs, which adds value to the final product.

The following are some of the labels and cartons made with UV embossed films:

He label

This is an aesthetic product label for an Indian deodorant brand. The label has been developed in-house by Holostik, from mastering to film making to registered printing and conversion. In this label, different effects have been transferred on MetPET film, including 3D PRI effect on the brand name HE and Magic DUO and controlled rainbow visualisation in the background. The labels have been developed in two different colours as per the requirements of the client. The labels give a unique look to the product, not found in any other competing brand.

Technical specifications: 50-micron MetPET film laminated with 62-gsm release liner, hotmelt pressure sensitive adhesive.

IFFCO edible oil label

The IFFCO edible oil label has been developed by Holostik for the ALFA range of corn oil products-sold across Middle East & Africa. The purpose of the label was to increase product sales, especially in supermarket chains, hypermarkets, etc and provide security against counterfeiting. The label has artistic drops with lens effect. The outer boundary of drops has a 3D PRI effect. The label not just enhances the brand aesthetics of the product but also provides it security against duplication. The label infuses the product with an attractive look to grab the customer’s attention in modern stores and big retail outlets.

Technical specifications: 50-micron MetPET film laminated with 62-gsm release liner, hotmelt pressure sensitive adhesive.

Agewell folding carton

This folding carton has been developed keeping in mind the high value content of a dietary supplement product - soft gelatine coconut oil capsules sold in South Africa and Nigeria. In this carton, Holostik has used the innovation of lens/3D effects on MetPET UV embossed film with registered printing. The film's unique property of showcasing different features makes the carton look appealing. Some of the unique features implemented in the product include 3D PRI effect in Agewell brand name on the front panel, dome lens effect in brand logo, complete background with pillar of light effect and 3D PRI effect in the images of coconut and leaves. With all these unique film effects, the product manufacturer has justified the high value content of the product. The effective packaging has leveraged the brand image on another level and makes it efficient against duplication.

Technical specifications: 23-micron UV embossed PET film, UV coating 5-gsm, 350-gsm FBBD.

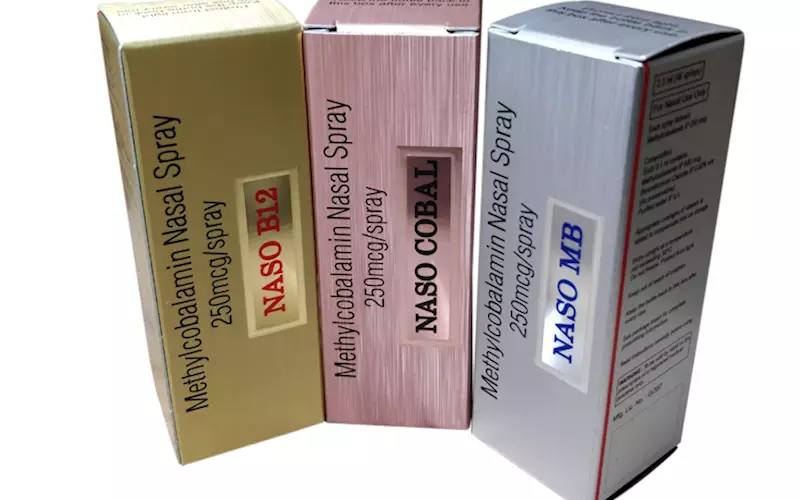

NASO folding carton

The folding carton has been developed by Holostik for a one-of-a-kind pharma product NASO- a vitamin B 12 nasal spray. The carton developed for the product has multiple aesthetic effects on its different panels. The front and back panel have a big dome lens with a PRI outline while the background has a brush effect. The address panel has three rectangular dome lens and TROIKAA branding with 3D PRI effect. The panel background has appealing dust effect. The carton accentuates the look and feel of the product. This enhanced visual appeal has helped the manufacturers to create a unique brand identity for the unique product.

Technical specifications: 23-micron UV embossed film, UV coating 5-gsm, 300-gsm FBBD.

See All

See All